Stick Welding with 3/16" 7018 electrodes

- HOME

- STICK WELDING

- Stick Welding

While filming this video , I was thinking about my very first stick welding job.

see more videos on stick welding

I was about 4-5 months into welding school when my instructor let us all know that a local welding shop was hiring a few welders.

We had a winter break coming and it was a chance to make a few bucks and get some experience.

So I went.

I took a mig welding test and bombed it.

But they needed someone for stick welding too and I raised my hand.

That put me sitting on a bucket for 10 hours a day burning 3/16" diameter E11018 electrodes on a high strength steel masthead support for a mobile drilling rig.

With only 4 months or so of welding training under my belt, I wasn't worth much to a company, but I earned my pay.

I could burn a rod pretty good and I burned lots of them.

I remember this older man that everyone called "Dad" and he took me under his wing and showed me a few tricks for wrapping corners, avoiding undercut, and making decent restarts.

I learned a lot during those few weeks, and even though it was a crappy job by anyone's standards, it taught me a few things.

And the main thing i learned was that I did NOT want to do that type of work for the rest of my welding career.

So I went right back to welding school and progressed to pipe and TIG welding.

Stick Welding with 7018 vs 11018 rods

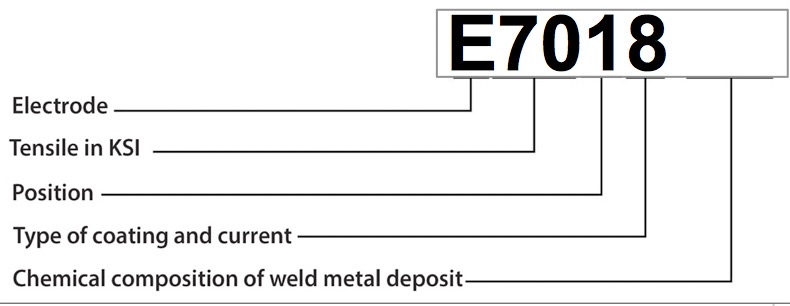

The numbers 70 in 7018 indicate a minimum tensile strength of 70ksi.

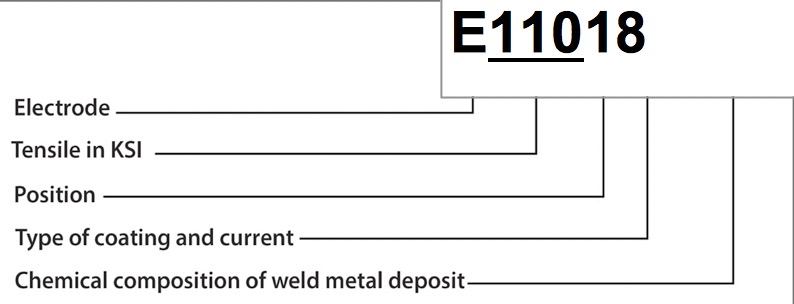

But there are stick electrodes that have a higher tensile strength than 100 and so another digit is needed.

So in the case of 11018 electrodes, the first 3 digits indicate tensile strength.

Small alloying elements like chromium, nickel, and molybdenum are added to 11018 to increase the strength but they burn very much like 7018 electrodes.

Both 7018 and 11018 rods are considered low hydrogen electrodes and should be used within a few hours or kept in a rod oven once exposed to air.

Some welding codes are very strict on how long a low hydrogen electrode can be stored on the air before it is no longer considered low hydrogen.

There are even limitations on the number of times a low hydrogen electrode can be reheated to remove hydrogen.

On that first job of mine, they were not too concerned about keeping the rods in a portable rod caddy during the workday, but i went thru a 50 lb can every day sitting on my bucket.