Stick Welding a 5F Weld test with 3/32" 7018

- HOME

- STICK WELDING

- Stick Welding a 5f Weld Test

This page is about stick welding a 5F weld test tube to plate.

A 5F tube to plate test is where the plate is vertical and the pipe or tube axis is horizontal.

Usually, there is a macro etch test along with some break tests to check for complete penetration into the root of the joint.

Complete penetration into the root does not mean full penetration all the way thru the back side...it just means into the root of the joint where the 2 members meet.

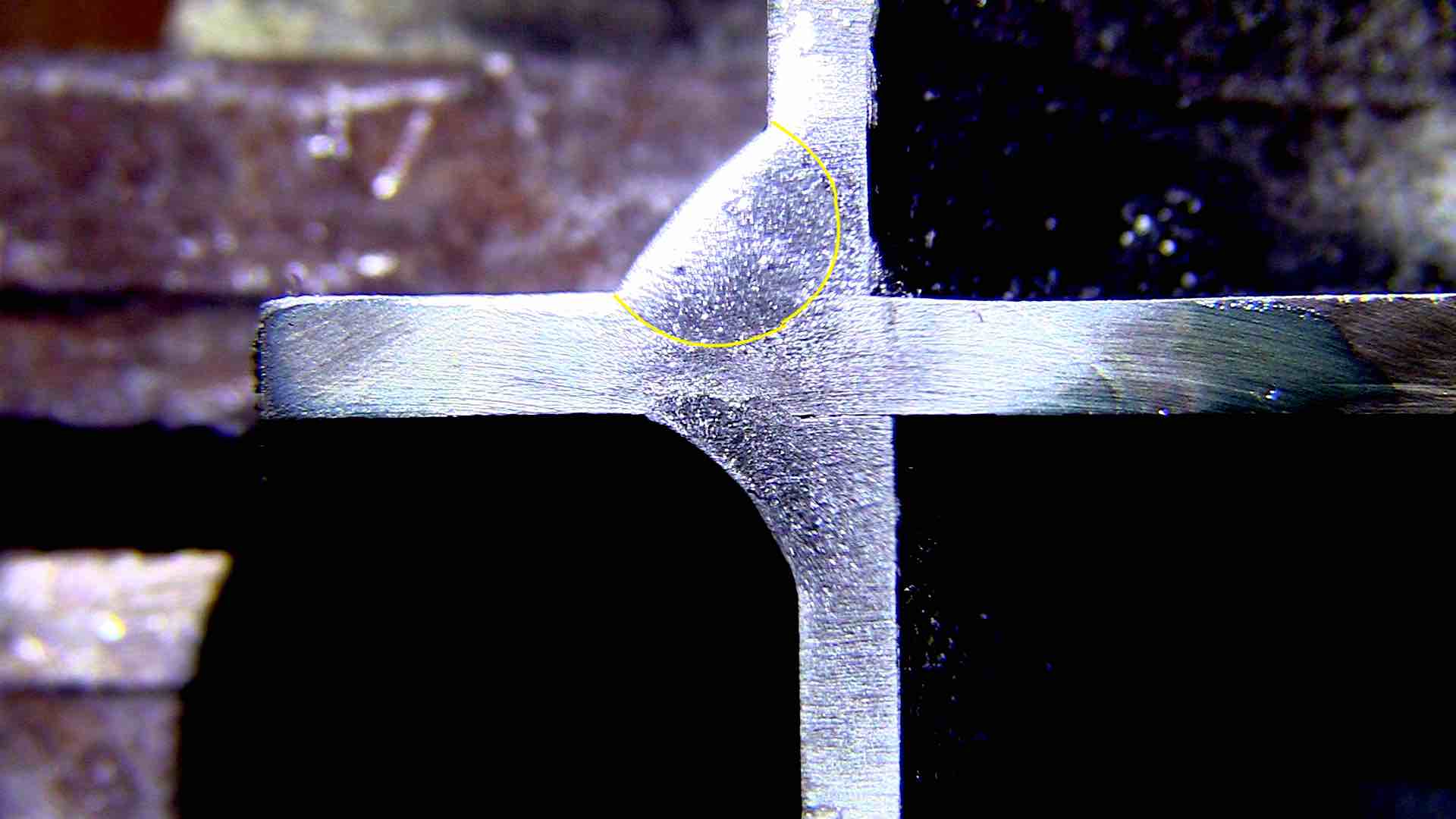

the image below is a cross section of the 5f tube to plate weld in the video.

the bottom weld is a 4f tig weld done on the back side to save metal.

You can see the video of the 4f tig weld here

Does anyone really need a 5f stick welding certification?

Here is a quick example:

My friend Andrew Cardin needed a certification to weld one single socket weld end cap.

Andrew has lots of pipe certifications for downhill xx10 welding but none of those certifications covered him for a one inch socket weld with 7108.

The engineers were saying he needed a 6g test. But for one single weld"

That seemed like overkill to Andrew so he went to the code books and quickly identified the 5f weld test as the simplest and least expensive test to take.

The 5F stick welding test using 3/32" 7018 was the simplest test that would qualify him to go make that single lonely 1" carbon steel socket weld on a LNG plant.

Pipe welding codes are all a bit different but most of them allow for a 5F weld test qualifying the welder for fillet welds in all positions.