Tig Welding a Steel Cube part 1

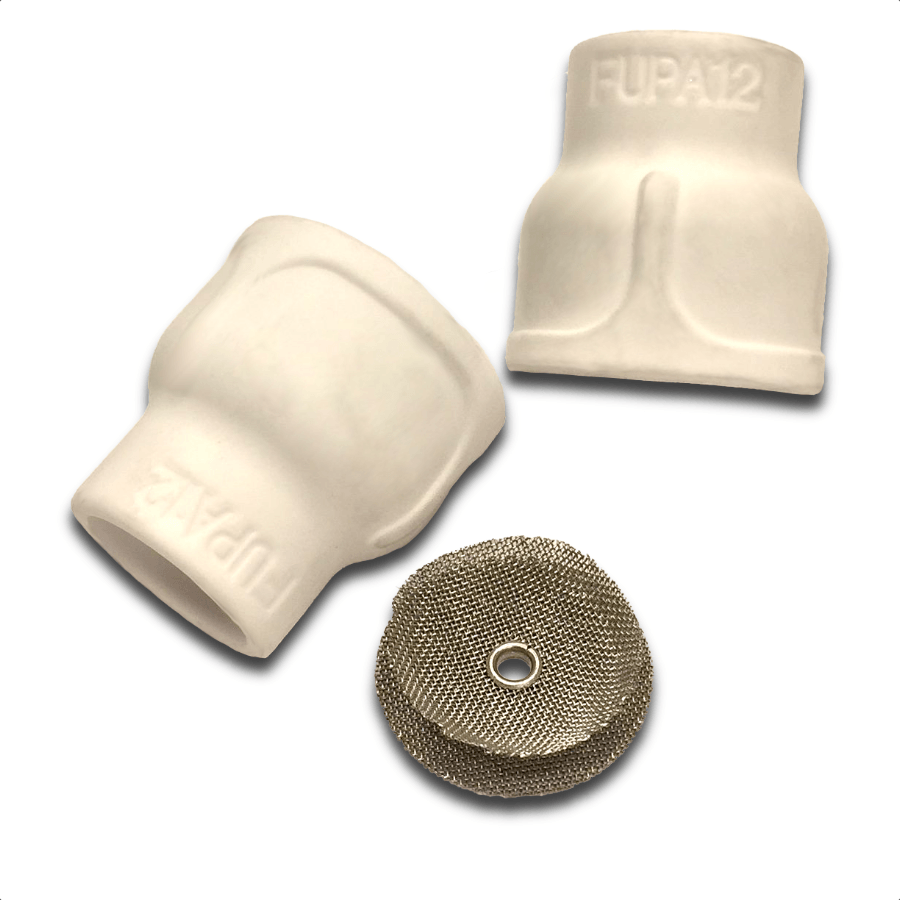

learn more about the furick #12 cup

Steel Cube TIG welding project

In this video, I am tig welding a carbon steel cube and experimenting with different filler wire types, and sizes as well as trying some pulse settings while tig welding a carbon steel cube.

This is the first of a 2 part video series and in the second video, I will fill the fillet area with silicon bronze to attempt a cool looking steel cube that can be used as a propping block, or a paper weight/conversation piece.

For the first run, I set the machine to 130 amps and used er309L 1/16" (1.6mm) filler wire.

309L is designed for welding carbon steel to stainless steel and is a good rod for dissimilar metals when you arent exactly sure what grade steel you are welding. (just to be clear, on anything critical, you must know the grade of steel in order to ensure good results)

I have used 309L successfully for modifying wrenches, stopping porosity when repairing a nasty sewer tractor, as well as tig welding stainless steel to carbon steel as it was designed for.

312 stainless is another good rod for the jobs I just mentioned...but 309 is usually much easier to find and usually cheaper too.

choosing the right filler metal

Filler metal size can make a pretty big difference. Choosing too large a filler metal can chill the puddle too much causing a very non uniform bead.

Too small a filler can be too flimsy, and requires a lot of feeding...sometimes even balls up before reaching the puddle.

For welding this cube, I found that 1/16" (1.6mm) was the all around best size.

But I also experimented with .045" (1.1mm) as well as 3/32" (2.4mm).

200 amps with the pulse frequency to 1.5 pps worked pretty well 2with a 3/32" size filler while using the "lay wire" technique.

I was not quite full pedal while set a 200 amps but pretty close at times.

If you are looking for an easy way to make a weld on an outside corner like this and your machine has pulse capability, consider trying it.

Once this cube cooled off , I used a wire wheel to shine it up to prepare it for the silicon bronze filler I will use to fill in the corner welds.

I think the silicon bronze will shine up nicely to make a nice paper weight or hand prop for future tig welding jobs.