Tig Welding a small Purge box

making a small argon purge box for tig welding small parts.

some small parts can be easily welded on the bench without any additional argon shielding.

But some parts can benefit from being welded in an argon atmosphere.

Some examples are:

click here to see part 2 of this purge box video

- titanium foot pegs for a dirt bike

- precision machined parts that require a touch up weld

- odd shaped parts with cavities that need to be shielded with argon

how to make a small argon purge box

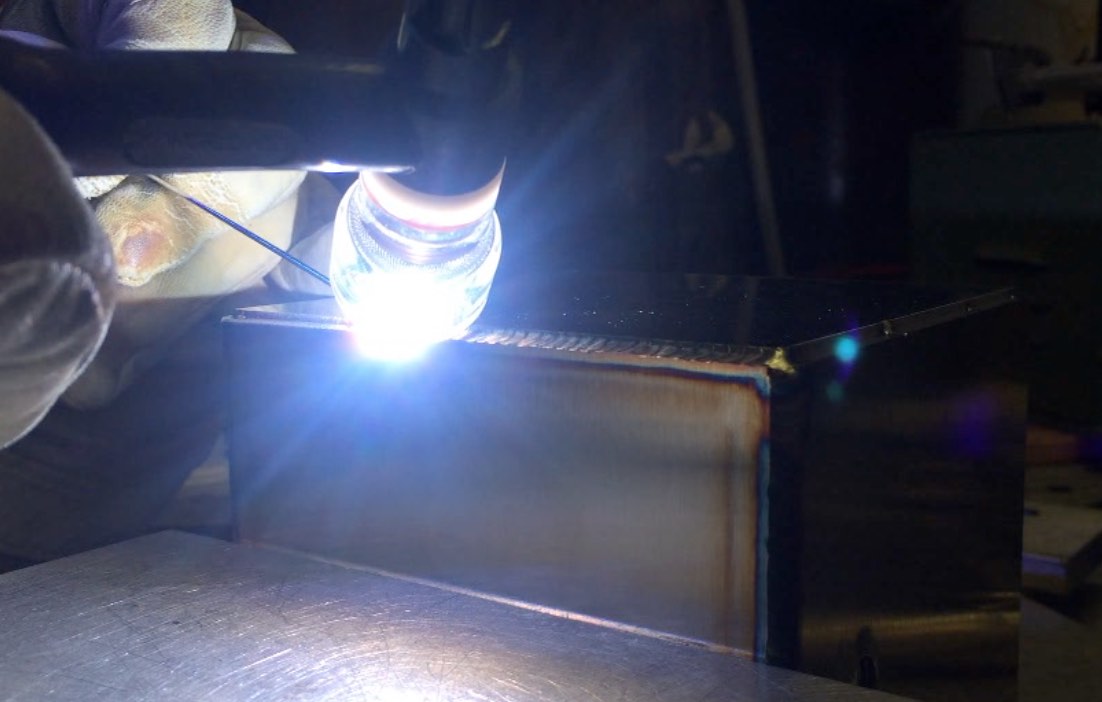

using 11 ga stainless steel, that was water jet cut... my friend Roy shows how he uses a #12 furick cup and chill bars to get great argon shielding on this small argon purge box.

An argon purge box is used not only for titanium parts, but also when a high quality weld is desired on small parts with hard to shield areas.

using aluminum for chill bars

The thinner the metal, the more important chill bars become.

The box being welded in the video is 1/8" ( 3.2mm) thick and does not really require chill bars. ( but they help)

But for .040" (1mm) thick stainless, chill bards would make a huge difference.

Chill blocks remove heat rapidly from stainless and help prevent distortion.

That is a good reason to save all the aluminum blocks you can so you can have an assortment of different sizes to use for chill bars when the need arises.

using a #12 furick cup to prevent discoloration is stainless steel

Discoloration is basically due to surface oxidation.

Discoloration in stainless steels might be tolerated for some applications.

But there are certain situations where the less oxidation the better.

using chill bars along with the Furick 12 cup lessens discoloration a lot.

click here or on the pic below to learn more about the fupa12 furick ucp

Once the argon box was welded, Roy added 2 sintered bronze air mufflers for diffusers. ( just search amazon for "sintered bronze air muffler" and you will see a variety)

A diffuser is used to allow the argon gas to flow smoothly and evenly and to provide a soft blanket of gas to the parts being welded.

..and Its a good idea to use a diffuser for purging anything.

it reduces turbulence and usually provides for a better, quicker, and more efficient purge.

and that is the whole idea of building a small purge chamber...to provide a quick argon atmosphere for tig welding without using a ton of argon gas.