Properties of Stainless Steel and how to weld stainless

Q: What is stainless steel?

A: Predominately Iron with 10.5% or more Chromium. Other elements such as nickel are sometimes added to achieve certain properties

Stainless steels are commonly divided into five groups:

*martensitic stainless steels

*ferritic stainless steels

*austenitic stainless steels

*duplex (ferritic-austenitic) stainless steel

*precipitation-hardening stainless steels

martensitic stainless steels

: the most common for types of martensitic stainless steels for aerospace usage are :410, Greek Ascoloy, Jethete

properties of stainless steels in the martensitic group are high strength and resist scaling and oxidation at elevated temperatures.

for knifemaking, the most popular martensitic grade is probably 440c. 440C can be hardened to 60 hrc

They are magnetic, hardenable by heat treatments, and are generally resistant to corrosion only to relatively mild environments. Chromium content is generally in the range of 10.5 to 18%, and carbon content may exceed 1.2%. The chromium and carbon contents are balanced to ensure a martensitic structure after hardening.

Ferritic stainless steels: are magnetic non heat-treatable steels that contain chromium but not nickel. 409, 430 , 436 Common use: auto exhaust pipes

properties of stainless steels in the ferritic group ...not hardenable by heat treat and hold up well at elevated temperatures.

Austenitic stainless steels: Usually contain 17-20 % Chromium, and 7-12% Nickel. (18/8) Non heat treatable 300 series is most common, 301, 303, 304, 321, 347

304 is the most widely used and is what you see in restaurants, on boats, pool ladders, etc.

properties of stainless steels in the austenitic group ... corrosion resistant, not hardenable by heat treat. very weldable.

Duplex (ferritic-austenitic) stainless steel

Has a combination of the properties of ferritic and Austenitic stainless steels. Widely used 2205 duplex SS contains 22% Cr and 5% Ni

Precipitation-hardening stainless steels:

Some contain as much as 1.5% Al which make them more difficult to weld.

17-4PH - easy 17-7PH - difficult

13-8MO - difficult

15-5 - easy

15-7MO - difficult

properties of stainless in the ph grades... much stronger than austenitic while still corrosion resistant.

Break it down!!!!!!!!

Hardenable stainless steels -martensitic, precipitation hardenable 410, Greek Ascoloy, Jethete, 13-8, 15-5, 15-7, 17-4, 17-7, A286

Non-hardenable,

ferritic grades like 409, 430, - 300 series......301,304, 321, 347,

300 Series stainless steels are among the most widely used stainless steels. They are classified as austenitic, and are hardenable only by cold working methods. These grades of stainless have chromium (approx. 18 to 30%) and nickel (approx. 6 to 20%) as their major alloying additions. Type 304 (also known as 18-8) is the most widely used alloy of all stainless steels.

301 An austenitic stainless steel. The high strength of this grade of steel in the six available conditions or tempers, its resistance to atmosphere corrosion and its bright, attractive surface make it an excellent choice for decorative structural applications in the Architectural, Automotive, Transportation, and Food Industries.

Strength of 301 work hardenable stainless steel

Condition Ksi

Annealed 75 1/4 Hard 125 1/2 Hard 150 3/4 Hard 175 Full Hard 185

301 ss Annealing Temperature 1850-2050°F

what does welding do to it??

welding will remove the work hardening effects.

303 ss A non-magnetic austenitic stainless steel specifically designed to exhibit improved machinability.

Can we weld it????

303 is not recommended for welding because of the sulfur that is added to improve machinability.

Sulfur causes cracking in most welds.

303 can be welded using special filler metals and techniques that minimize dilution and heat input. (but only for low stress non-critical applications)

304L

Chromium-Nickel austenitic alloy. Used for a wide variety of applications, this is one of the most familiar and most frequently used alloys in the stainless steel family.

Applications:

Food and beverage, Pulp and Paper, Chemical Processing, Transportation, Automotive

321 and 347 stainless

Stabilized stainless steels which offers an excellent resistance to intergranular corrosion following exposure to temperature in the chromium carbide precipitation range from 800 to 1500 Deg F.

What does stabilized mean??

stabilized stainless steels ...refers to additions of titanium or tantalum / columbium that binds up carbon or stabilizes carbon and prevents carbon from combining with chromium.

Applications; Aerospace, Refining, Automotive

AISI/SAE Stainless Steel Numbering System Alloy numbering systems vary greatly from one alloy group to the next. To help alleviate this problem the Unified Numbering System (UNS) for metals and alloys was developed.

To make things more complicated, hardly anyone uses this new numbering system NUMBERING SYSTEMS;Oh well, so there is no simple numbering system!!!

Remember this:

300 series are approximately 18/8 Cr, Ni and are non heat treatable

400 series are mostly straight Cr (around 12%)

Grades like 17-4, 15-7 and anything with a PH behind it is heat treatable

300 series SS: food service industry

400 series (409 is most commonly used for auto exhaust)

Precipitation Hardening Stainless Steels common in aviation and aerospace welding...harden by extended time at elevated temperature

HARDENING MECHANISMS

300 series can only be work hardened and can not be hardened by heat treat

martensitic grades like 410 harden by reaching a transition temperature and then cooling quickly

precipitation hardening grades like 15-7 and 17-7 harden by reaching an aging temperature for a prescribed time period

Best practices

NEVER USE CARBON STEEL WIRE BRUSHES ON STAINLESS STEEL MAKE SURE MATERIAL IS FREE OF CONTAMINANTS (OIL, PLASMA SPRAY, OXIDATION etc.) NEVER WELD WITHOUT BACKUP SHIELDING GAS LIMIT HEAT INPUT ANTICIPATE DISTORTION USE THE CORRECT FILLER ROD

More on welding 304 stainless steel

What are the properties of stainless steel ....and What makes Stainless Steel Stainless?

Chromium, Chrome, Cr...thats what. in order for a stainless steel to be called a stainless steel, it has to have more than 10% chromium.

first lets talk about the most common run of the mill stainless steel used all over the world.

304 stainless. 304 contains roughly 18% chromium, 8% nickel, and the rest is iron. its also known as one of the 300 series stainless steels, also known as 18/8 stainless.

Have you ever heard that stainless steel wont rust?

Well guess what? It will rust if not welded using the right methods,and it will get severe corrosion pits if exposed to certain environments. Especially if welded using the wrong methods.

What are the wrong methods? Here Are Some:

Using a Carbon Steel Wire Brush Or Wire Wheel

Using a Grinding Wheel That Has Been Used On Carbon Steel

Using a Wire Brush Or Wheel That Has Not Been Dedicated For Stainless Steel

Getting The Weld Too Hot And For Too Long

Too Much Oxidation In The Weld...( A Black Weld Can Be Sanded Smooth And Polished Shiny But That Does Not Change The Fact That It Got Hot And Oxidized)

Wrong Rod ( 308L Is The Preferred Rod For Welding 304 Stainless Steel...The L Is For Low Carbon)

Insufficient Shielding Gas

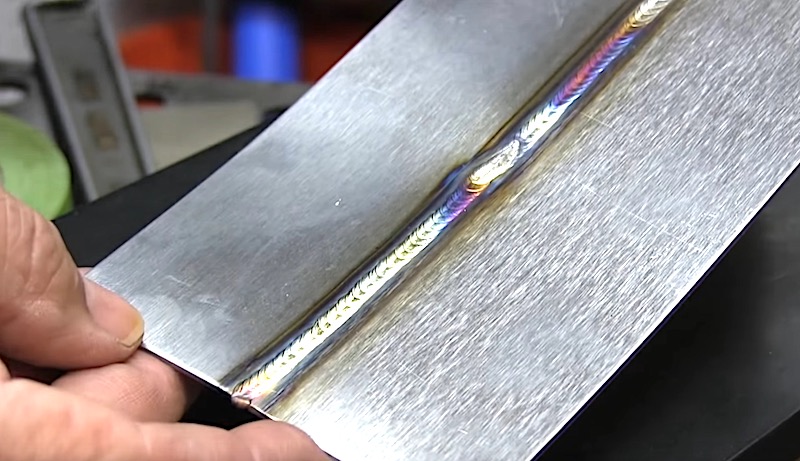

No Shielding Of The Back Side On A Full Penetration Weld

Abusive Grinding

Using A Carbon Steel Brush Or A Brush Or Grinding Wheel That Has Been Used On Carbon Steel Can Embed Carbon Or Iron Particles In The Stainless And Cause Rusting Later On

Getting The Weld Too Hot For Too Long Can Cause Rusting Later On Too.

Getting stainless too hot lets the chromium combine with carbon and that leaves areas depleted of chromium and chromium is the element that resists corrosion.

not shielding the back side of a weld with argon causes something called sugaring or granulation. Again the chromium can be depleted from the molten metal not being protected.

Another problem is all the pits and crevices in the sugared weld metal that are a natural place for corrosion to begin.

When you first learn to weld stainless steel, its easy to get some misconceptions.

Its easy to assume that mistakes made welding stainless can be undone and everything will be fine.

So you get a weld that is black instead of shiny. You just grind and polish and no one will ever know. right?

maybe, maybe not.

Welders who have years of experience know different. And I am not just talking about welding experience.

I am talking about experience being around the same welds for years after they have been put into service.

I have a friend who installs stainless steel piping for sanitary application and also does maintenance on the same plants he has piped in. He gets to see which welds rust later. He remembers when he had a purge problem or when he got a weld too hot.

It bites him squarely in the ass.

Review...

what are some of the properties of 304 stainless?

pretty good corrosion resistance non magnetic ( unless severely cold worked) resists rust not very thermally conductive moderate strength can not be hardened by heat treatment exit properties of stainless steel and learn more about the tig finger heatshield