Mild steel TIG Welding

First of all What exactly is mild steel?

Mild steel is a term used to describe plain low carbon steel.

Low carbon steel is referred to as "mild steel" because it contains a relatively low percentage of carbon (typically 0.05% to 0.25%).

The term "mild" signifies its softer and more ductile nature compared to higher carbon steels. Since it has a lower carbon content, it does not harden significantly when welded or when it is heated and then quick cooled or quenched.

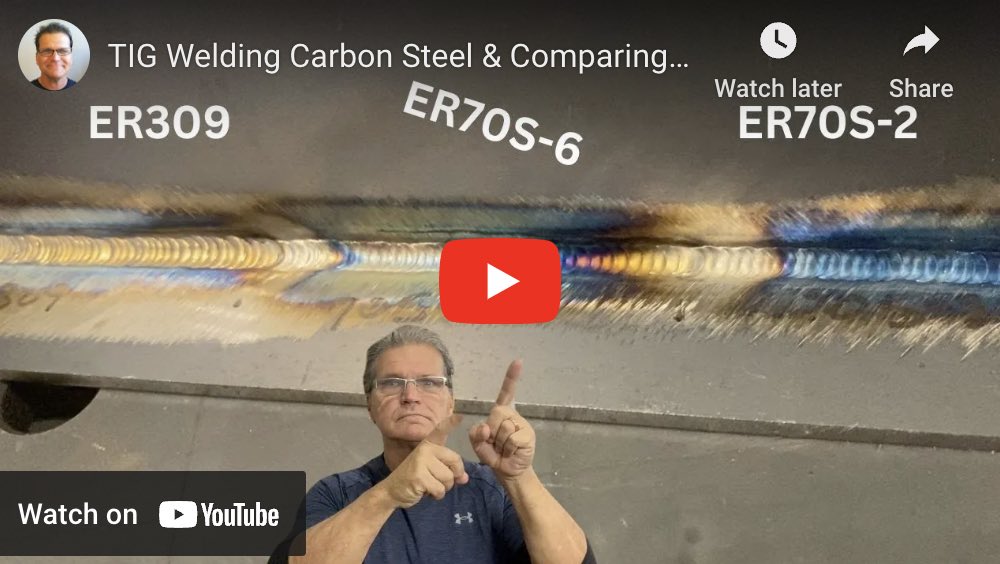

TIG welding a mild steel Tee joint 11ga cold rolled steel

The video above shows mild steel tig welding on a 11ga cold rolled tee joint.

Travel speed is a big factor and the faster you can travel the more amperage you can use.

If you have ever seen an episode of "Forged in Fire" where they make knifes, swords, and other blades, you may have seen the contestants heat up a blade to cherry red and then quick cool it in oil in order to make the blade hard.

After heating and quenching, the contestants test the hardness of their blade with a file to see if it hardened.

Occasionally, a contestant will accidentally chose mild steel out of a pile of scrap to make their blade and they learn quickly that mild steel wont harden.

Why is mild steel easy to work with compared to high-strength steel?

- Higher Ductility & Malleability – Mild steel is more ductile and malleable, allowing it to be easily cut, bent, and shaped without cracking. High-strength steel, on the other hand, has increased hardness and tensile strength, making it more difficult to form and shape.

- Lower Hardness – The lower carbon content in mild steel makes it softer, which means it can be machined, drilled, and welded with less wear on tools.

- Easier Welding – Mild steel is easier to weld because it does not harden significantly during the welding process, reducing the risk of cracking. High-strength steels require careful control of heat input and special filler materials to prevent brittleness and failure.

- Less Brittle – High-strength steels contain additional alloying elements and have a higher carbon content, making them stronger but also more brittle. Mild steel, being more ductile, can absorb impact and deformation without breaking.

Because of these characteristics, mild steel is widely used in construction, automotive manufacturing, and general fabrication where ease of use and cost-effectiveness are priorities.

What is the best filler rod to use for mild steel?

What filler metal is best for mild steel tig welding? ER70S-2 OR ER70S-6?

Walking the cup vs Freehand on a Mild Steel 3F tee joint

Outside Corner Joint 11ga mild steel

Corner joints and lap joints 11ga steel

Arc length tips

Mild Steel TIG welding is usually the very first thing you do when learning to TIG weld.

In welding school, you might stay on mild steel for weeks before tig welding any other metals.

I think that method of teaching has room for improvement.

I think a better way to learn to TIG weld is by alternating between aluminum and mild steel.