MIG Welding Vertical

3 Tips for Mig Welding Vertical

- Use lower settings than for flat

- keep your stickout short (for short arc mig)

- Use a technique that keeps arc on leading edge of puddle

Push vs pull and MIG Welding Vertical uphill

Factory Recommended settings vs MIG like TIG

One Technique for all Positions 1F, 2F, 3F, 4F

These are three of my Best MIG welding videos showing different machines, different techniques, and instructive arc shots.

If like what you see here, you might want to check out my DVDs on mig, tig, stick, and pipe welding.

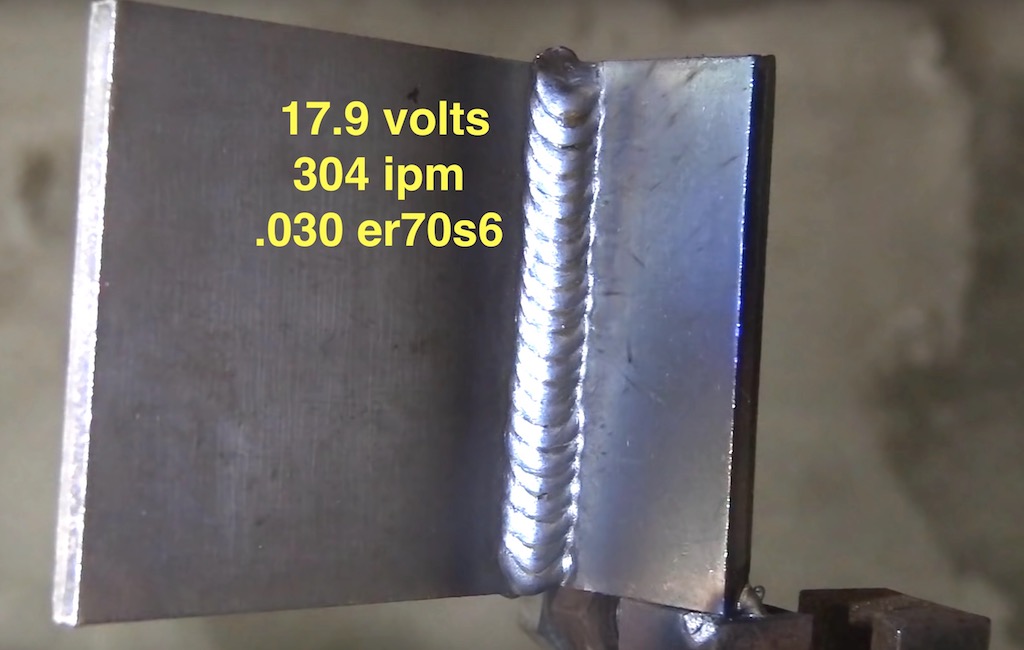

Its all short circuit MIG with C25 gas (75/25 argon/co2).

Factory recommended settings for mig welding are intended to be used in the flat and horizontal positions.

They are a pretty good place to start and are usually good and hot.

But when you start mig welding vertical uphill, its difficult to handle the heat that works great for flat and horizontal welds.

Gravity pulls the molten puddle downwards so it helps to lower both voltage and wire speed for mig welding vertical uphill.

Since almost every mig welding machine has a settings chart on the inside of the feeder door, all you need to do is select settings for one or two thicknesses less and it usually gets you right in the ball park for a vertical uphill mig weld.

If the machine has auto settings, just selecting a thinner material thickness does the trick. ( I also lower my wire speed by about 10% to give me a little more time on odd shaped joints like tubing clusters).

Make sure to pay attention to your wire diameter too.

The mig settings charts are helpful but you definitely need to be sure you are using the right settings for the diameter wire you are using.