Mig Welding Uphill Lap joints

When you begin mig welding uphill, thats where the fun starts.

Mig is fairly easy to learn in flat and horizontal positions where gravity is not a problem...but as soon as you try to weld uphill, technique becomes really important.

So in this weekly video, I am showing 2 popular techniques that work especially well for mig welding uphill on both lap joints and tee joints.

2 techniques for Mig Welding uphill

click here for more mig welding videos

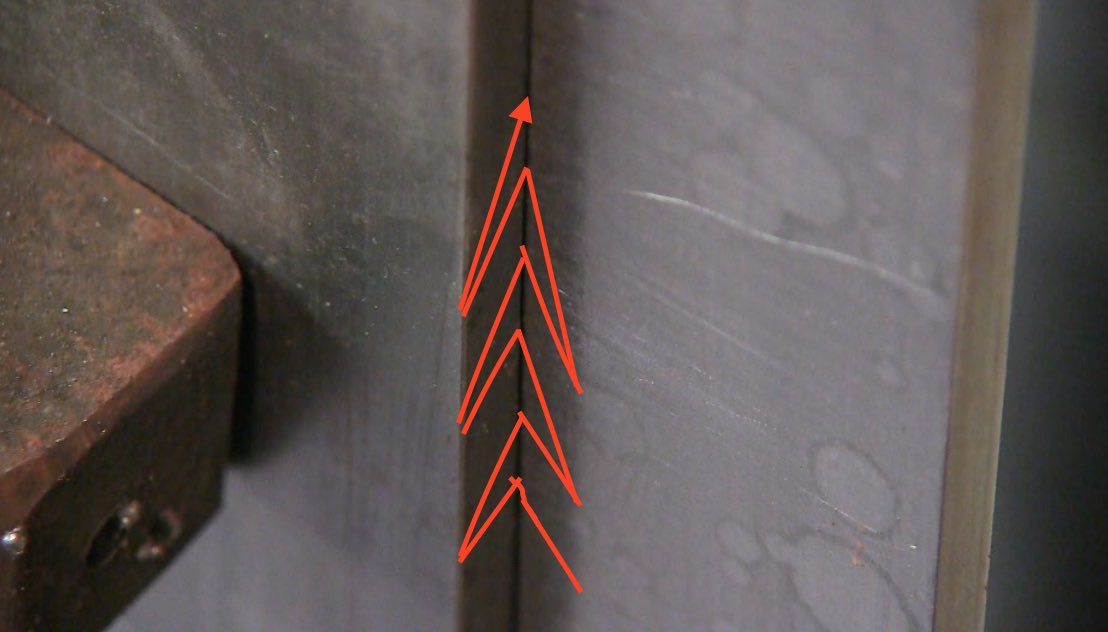

The first technique in this video is known as the "upside down V" technique.

A series of upside down Vs trace the leading edge of the puddle and provide for penetration as well as a way to let the metal to be manipulated in a way that limits convexity.

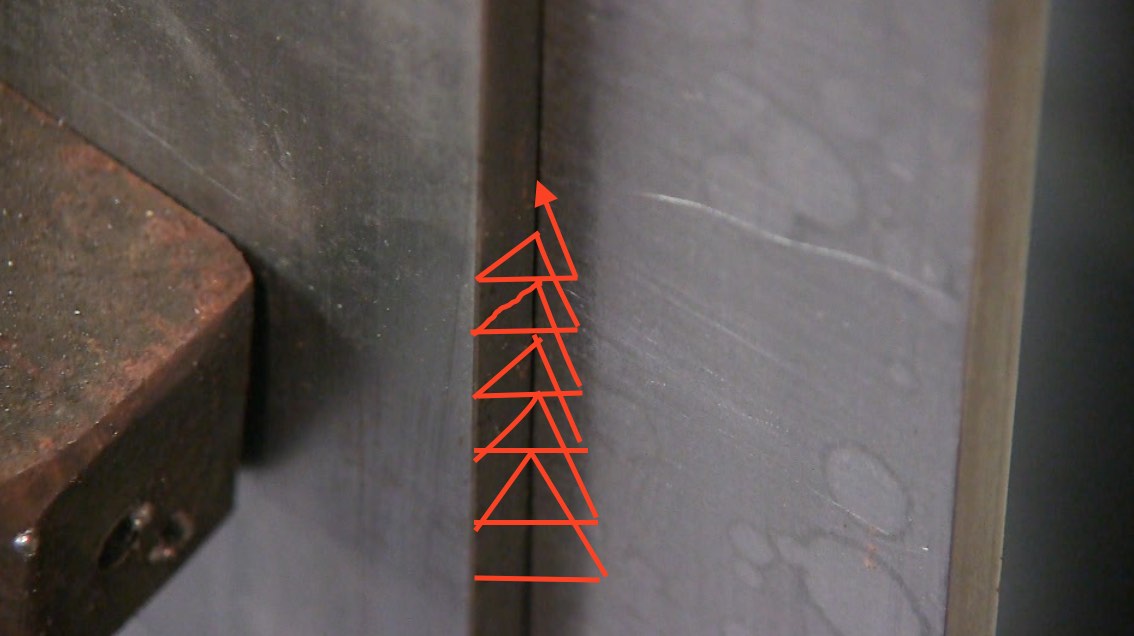

The second technique is called the triangle technique.

On a Tee joint, the direction of travel doesn't seem to matter at all but for lap joints, it seems to help when the upward travel happens on the side where there is no corner. Either direction works but its easier to prevent undercut if the downward motions are on the corner side.

For the first welds I set the machine to 19 volts and 280 inches per minute of wire speed.

19 volts and 280ipm are actually the recommended settings for 11 ga steel in flat or horizontal position...but when you weld vertical uphill, you typically need less heat to get penetration because gravity helps keep the puddle behind the arc.

I also welded a lap joint using slightly hotter settings of 20 volts and 290ipm and while penetration was slightly better, (not much) the convexity was a bit much...and would not be acceptable under certain welding codes.

Why too much convexity is not good

Excess convexity makes for an abrupt change in the shape the weld and can be a stress riser.

That is why some welding codes like AWS D1.1 have limits for convexity.

We think of bridges and buildings as being completely still but they actually undergo a certain amount of flexing. Whether from thermal expansion and contraction, or from dynamic loading like tractor trailer rigs passing over thousands of times.

A stress riser created by excessive convexity can be a place where a crack is more likely to occur.

and once a crack starts, it tends to grow.

Quick Summary for mig welding lap joints and tee joints uphill

- KYSS...Keep your stickout short. Stickout is the amount of wire sticking out between the contact tip and the arc... If you aim for about 3/8" (9mm) stickout, you will probably have more stickout than you think.

- Use a technique that helps keep the arc on the leading edge of the puddle. Both techniques shown in this video help keep the arc where it needs to be to get adequate penetration.

- Set the voltage and wire speed high enough to get penetration into the root of the joint...but not so high that you cant control convexity.

see the newest products on the weldmonger store