Mig Welding Tips - Mig Welding Tip #16

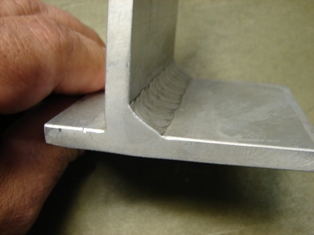

When welding a fillet weld, like for a t joint or lap joint, the size or leg of the weld should be approximately equal to the thickness of the parts welded...or at least as big.

Make the weld the right size but not too big...It is not always a good idea to overweld things.

If metal thickness is 1/4”, a 3/4 “ weld is not going to make the joint any stronger than a weld that is at least 1/4" in the thinnest area.

So if the metal is 1/4“ thick, make the weld 1/4” and not much bigger.

Along the same line of thinking, if the metal to be welded is 1” thick, a single pass fillet weld that is 5/16” is not going to be nearly strong enough. But remember, when you are welding a joint with different thickness like for instance a 1/4“ piece welded to a 1” thick piece, you only need a 1/4” weld .

When drawings are used, welding symbols are used to specify the size of the weld. But there is a bunch of stuff that is welded without drawings where common sense is the only thing used.

more mig welding tip articles