Mig Welding Square Tubing 11ga

This page is about mig welding square tubing in 11ga thickness.

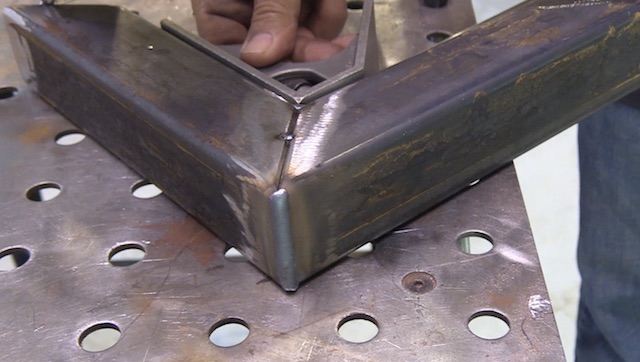

I got some 45 degree miter cut square tubing just for this video and what I want to demonstrate in this video is how weld metal shrinks and how you can use that to your advantage in keeping things square.

I tack welded things up using a tig welder and then mig welded them outside the shop using a lincoln powermig 210mp using .025" er70s-6 wire.

I like to use this smaller diameter wire on small parts and thin metal because I get really crisp arc starts and a smooth arc.

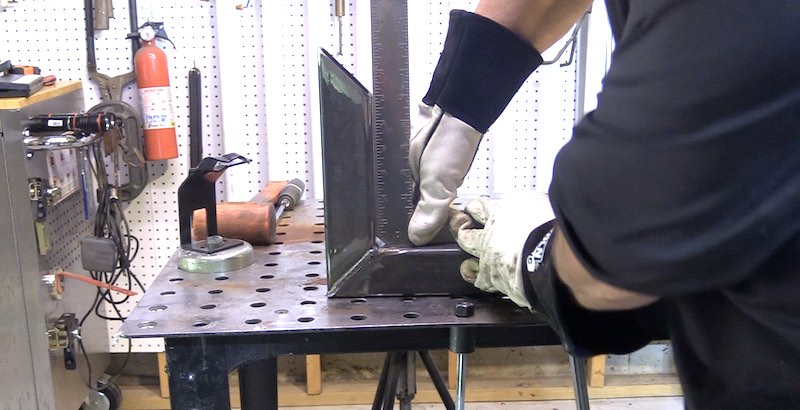

But the main thing in mig welding square tubing is often just keeping things square and straight without distortion.

Bead placement and direction of travel can have a big impact on keeping something square.

Remember that direction of weld travel can influence how a part distorts because weld metal shrinks....and it shrinks in the direction of travel.

So I usually weld the outside corner first on a 45 degree miter cut because that weld typically will not pull or move much.

Next, I weld the 45 degree joints from inside to outside.

Lastly, I weld the fillet weld in the crotch of the joint.

By the time I have the first 3 welds done the joint is pretty much locked in position and wont move much.

But if it does move, it will pull inwards so you have to keep that in mind.

My settings for the 11ga square tubing were 20.5 volts and 345 ipm using .025" wire.

I think for this machine...the powermig 210mp, .030" wire is probably the best all around wire size because it lets you go down to really thin metal like auto body panels...and it also allows for thicker metal up to around 1/4" thick.

but I really like using .025" wire for light duty mig welding square tubing...especially for thinner wall tubing..

... if I were to be routinely welding thin metal, I would definitely keep .025" wire on the machine...and another benefit for using .025" is if you weld using an extension cord on 115v.

This welder is a dual voltage and runs off 115v or 230v power using adapter plug pigtails.

It does better than most other welders on 115v but it will still pop a breaker if you push the limits too much.

using .025" wire seems to help get the most out of this mig welder when I am plugged into 115v power.