Laser Welding Cut and Etch Tests

The first video I posted generated a lot of comments asking for some laser welding cut and etch tests.

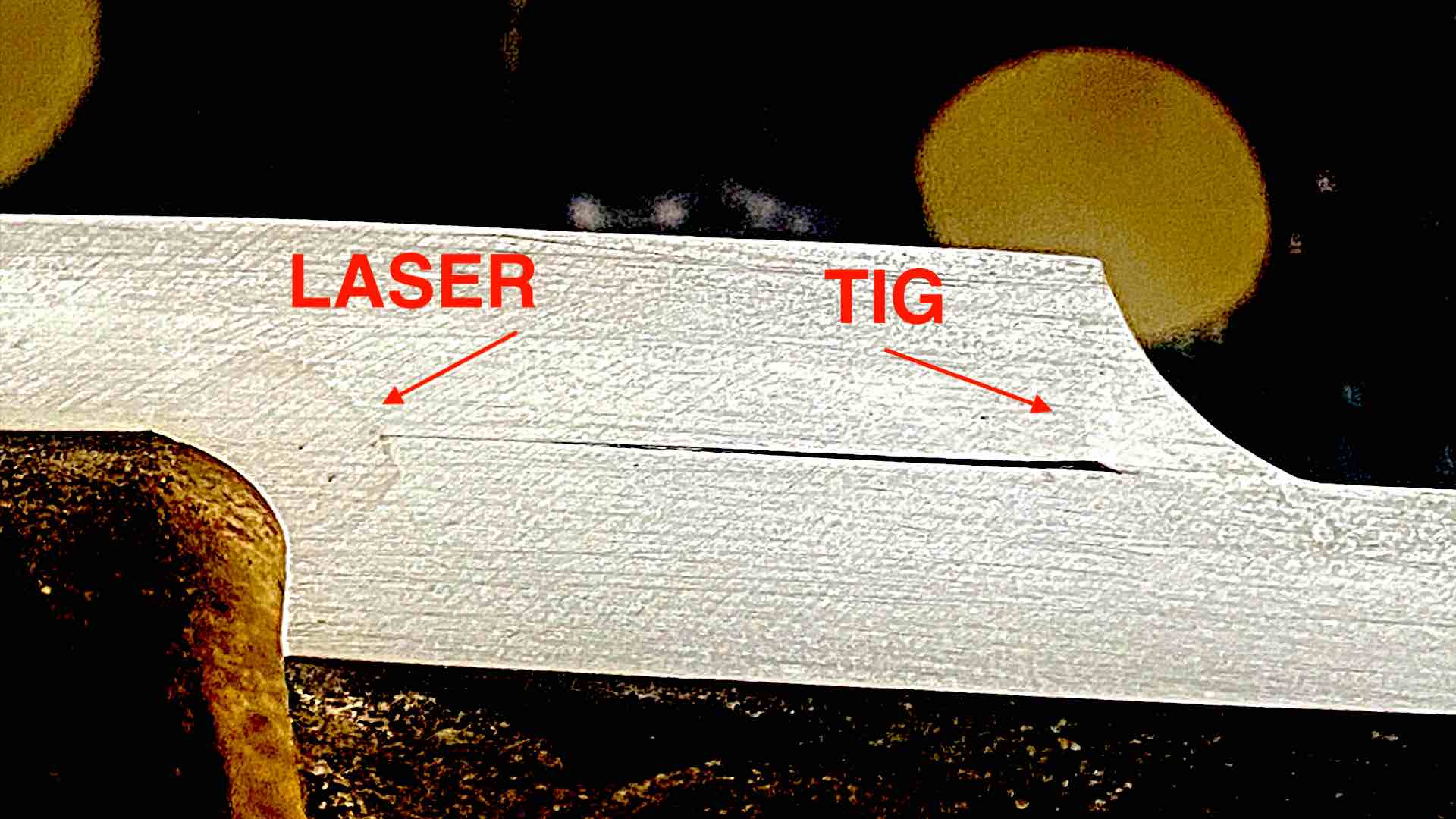

So I saved the samples that were welded at Denaliweld laser headquarters and did some cut and etch tests on them and compared them to an aluminum weld made on the same material.

A visual test can only tell you so much. That is why I like to test things using the cut and etch method.

The Denaliweld Hand held laser makes a very small weld but the cut and etch test reveals that a very small weld can actually have a greater throat size than a larger leg size TIG weld.

So will Hand Held Laser replace TIG Welding?

I think there will always be a place for manual TIG welding but for some manufacturing applications, the benefits of Laser welding cannot be ignored.

Not only is travel speed much faster but the heat affected zones of stainless and aluminum will be a big factor as far as corrosion resistance and strength.

I see hand held laser welding being utilized more and more in the automotive manufacturing industry as well as aerospace components. The low heat input and low distortion benefits will be a key factor on aluminum alloys, titanium, and other specialty alloys.

I look forward to learning more about both the capabilities and limitations of hand held laser welding.