How to Weld Stainless Steel

If you searched for "how to weld stainless steel, this video should help.

Take 10% OFF All TIG Accessory Kits.. YEP! Even the PRO klts. That saves you $40 right there alone.. Deadline for the kit deal is Sunday, 10/23 at midnight!

use code FALLKIT10 at checkout

10% off tig cup kits here

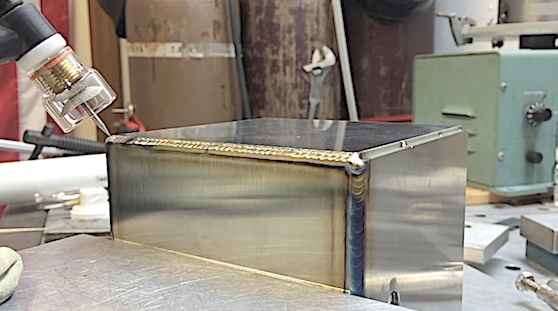

The main things to give attention to for tig welding stainless steel are:

- TRAVEL SPEED

- GAS SHIELDING

- BACK PURGING

- CHILL BARS

- USE ONLY SS WIRE BRUSHES

Any "how to weld stainless steel" article should address these best practices.

TRAVEL SPEED

Travel speed is an often overlooked factor in the way it affects stainless steel.

300 series stainless like 304L can lose stainless properties if the metal is kept at too high a temperature for too long.

Travel speed has a great affect on that so a great tip for anyone learning how to weld stainless steel is to pay attention to travel speed.

...and not only Travel speed but getting the puddle started quickly to prevent heat from building up.

Once heat builds from a slow start, it can be hard to outrun it.

GAS SHIELDING

Stainless steel loves Argon.

So using as large a cup as practical can really help you get a better weld.

Gas lens cups help...But specialty cups like the Furick jazzy 10 and Furick 12 work even better because of the added diffuser screens.

When a stainless puddle gets oxidized, it does not flow easily and requires more amperage to flow. Proper shielding prevents oxides from entering the puddle.

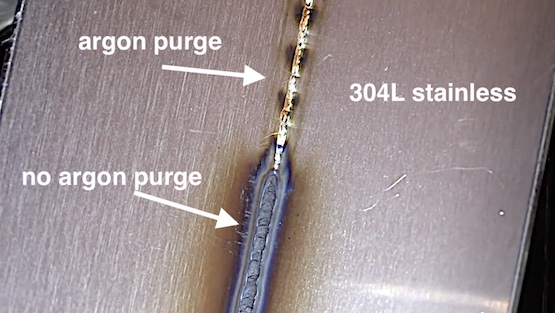

BACK PURGING

When the back side of a stainless steel weld becomes molten, it gets granulated.

Another slang term is it "Sugars".

No matter what you call it, its not a good thing.

Argon shielding on the back side prevents Sugaring.

Sometimes you can get by with aluminum or copper backing but for the highest quality, argon purging is usually best.

There are certain industries like food service, nuclear, and semiconductor industries that require a high quality argon purge on the back side with no other options.

CHILL BARS

Chill bars are not always possible to use but when they are, I recommend it.

chill bars not only prevent distortion but pull heat out of the part so that a smaller cup can give the same results as a larger one.

USE ONLY SS WIRE BRUSHES

Use only Dedicated Austenitic Stainless Steel wire brushes.

Dedicated means brushes that have only been used on stainless steel.

When you wire brush hot stainless steel with a wire brush that has carbon steel particles on it, you risk embedded carbon.

This situation can cause rust and corrosion.

It doesn't always show up right away either. It could take weeks or months.

WHAT IS PASSIVATION?

Passivation is a chemical treatment that removes free iron from the surface of stainless steel parts.

Sometimes a low electrical current is used along with a chemical solution.

Food service industry and pharmaceutical industries often require parts to be passivated after welding.

Frequently asked questions for How to weld Stainless Steel

what type of welding is best for stainless steel?

Stainless steel can be welded using TIG, MIG, Stick, or Flux Core but...

Unless we are talking about a high production environment of 11ga or thicker stainless steel, TIG welding is the most versatile and precise method for welding stainless.

Can a normal welder weld stainless steel?

Any welder who is proficient at tig welding carbon steel and weld stainless with a few tweaks.

As far as welding machines, most DC stick welding machines can be used for scratch start tig welders.

Any DC tig machine is capable of tig welding stainless steel.

Is welding stainless steel difficult?

stainless steel is slightly more difficult than carbon steel.

2 main issues are:

1. using best practices outlined in this article to retain the stainless properties

2. stainless steel warps more easily than carbon steel

stainless steel is not as thermally conductive as carbon steel and that factor allows heat to build up.

excessive heat build up not only contributes to loss of stainless properties but can cause distortion.

getting a puddle established quickly and getting moving along with using adequate travel speed will help prevent excess heat buildup.