How to TIG Weld Stainless

If you searched for "How to TIG Weld Stainless" you are in the right place.

This video shows tips for tig welding Stainless steel coped tubes along with some tips for purging stainless steel.

click on images below to visit the store

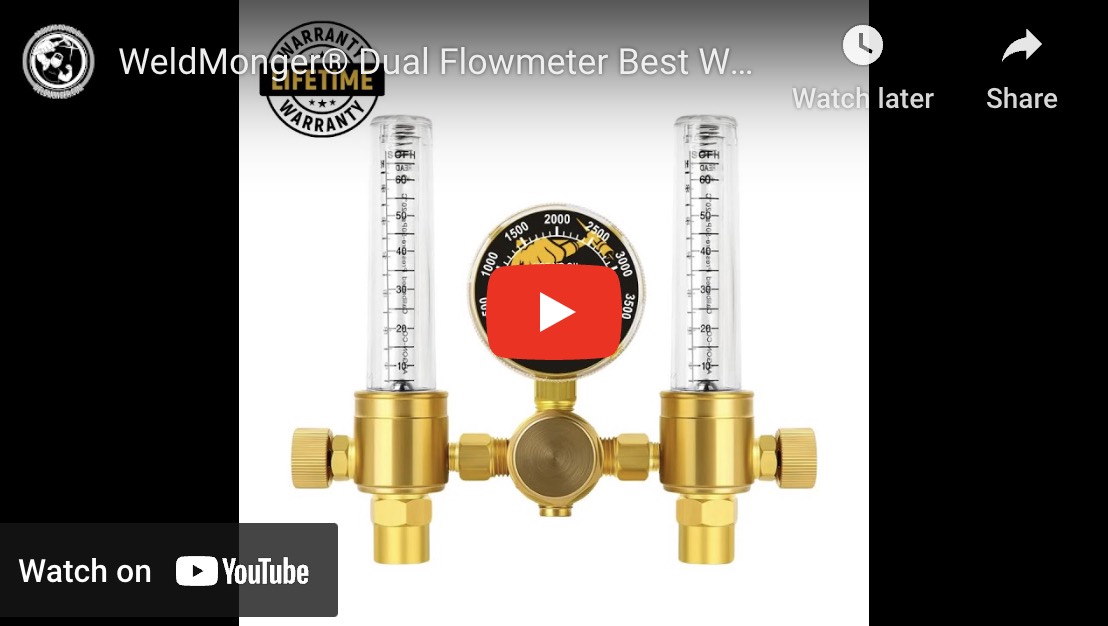

pictured below is the dual flowmeter, you can see it on my store here

Tips for How to TIG Weld Stainless Coped tubes

watch more tig welding videos

There are some best practices for TIG welding stainless steel that apply to nearly every situation.

1. Practice the 3 c's of tig welding stainless steel

- clean

- clean

- clean

What that means is make sure the edges are free from plasma dross,

remove all tape residue, glue, adhesive, oil, etc.

some stainless steel sheet comes with a peel coat and once that peel coat is removed, all that is usually needed is a solvent wipe and possibly deburring.

clean the filler rod too

- HOME

- Tig Welding Stainless

- Tig Welding Stainless Steel

- How to Tig Weld Stainless

- to prevent heat building up , get your puddle established quickly and get moving. when I say quickly, I mean less that 2 seconds.

- always be comfortable and use a TIG Finger if you need to prop

- Keep your electrodes sharp and free from crap

- use a gas lens cup like the Jazzy10 furick cup or furick ceramic 12

- keep the hot tip of the filler rod shielded in the argon

- use a filler rod one size smaller than what works best for carbon steel

- only 2/3 the amperage is required on stainless as compared to carbon steel ( on this job the thickness was .120 and amperage was set to 120 but only full pedal for the first few dabs)

- use only new stainless wire brushes or wire brushes that have only been used on stainless steel

- purge the back side when required. a weldmonger dual flowmeter makes this easier

- an argon purge is sometimes required by code or welding procedure but sometimes aluminum or copper backing works fine.

- if the hot tip of filler rod gets oxidized, snip it off with wire cutters or dykes.

- use matching filler metal or as close as possible...if the part is 316L stainless then use 316L filler wire

- dont keep the part too hot for too long.

TIG Welding Stainless Steel pipe Root pass technique

This short video shows bridge tacks vs penetrated tacks, root pass technique and all settings used

Check out this stainless steel manifold video

The Stainless Steel manifold welded in this video is a great example of purge requirements.

Sometimes an argon purge is completely needed.

other times, a copper or aluminum backing is the way to get the job done.

This stainless steel manifold did not really required an argon purge so I used aluminum for backing to prevent distortion as well as severe oxidation also known as sugaring.

The final welds were purged in case I accidentally penetrated all the way thru.

Outside corner welds were made using an aluminum angle bar.

Things to consider when welding stainless steels

Stainless steel is more expensive than carbon steel and is usually only used where corrosion resistance is very important.

The procedures used can either maintain stainless properties or destroy them.

Limit heat input by avoiding excessively slow travel speeds.

use only stainless steel wire brushes and abrasives that have only been used on 300 series stainless.

follow interpass temp limits in the welding procedure

to improve corrosion resistance after welding, consider electropolishing