How to TIG Braze

...on a file for a knife handle

- HOME

- TIG WELDING

- Tig Welding

- How to Tig Braze

This video is about How to TIG braze a knife handle on a file.

Have you ever tried to weld a file? or other high carbon steel...only to learn that it was a bad idea.

Welding high carbon steel without the right filler metal and preheat usually results in immediate cracking.

But TIG brazing is very different than tig welding.

That is why I made this video to help you learn how to TIG braze using a simple knife project.

I have been wanting to try this for quite a while and I thought it would be a fun project and also a good lesson in basic welding metallurgy.

Basic metallurgy of Files, and high carbon steel

Files are usually made from either plain high carbon steel... or chromium alloyed high carbon steel.

High Quality files are often made from the chromium alloyed high carbon steel.

Either type contains approximately 1% carbon.

With that much carbon, the problem with welding is that the metal will usually become too brittle and crack.

That is why brazing with a brass or bronze filler with an oxy fuel torch is a popular method of joining and repairing cast iron parts.

But you can also use the TIG brazing process with good results.

I have repaired many cast iron parts using Aluminum Bronze filler rods and a tig welder.

A strange thing happens when you overlay silicon bronze or aluminum bronze over a carbon steel.

The bronze filler metal metals around 1900F so it is possible to not get the base metal hot enough to make the high carbon steel brittle.

But another thing that happens is that the copper alloy is much more thermally conductive and so much of the heat seems to be confined to the bronze deposit.

As I brazed bead after bead, I noticed that the red hotness was not transferring to the file.

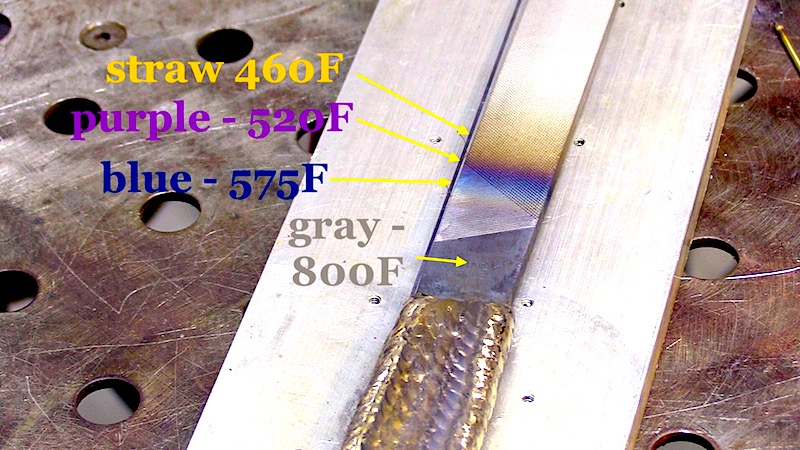

It appears I only heated the file metal next to the braze deposit to around 800-900F....not enough to transition to a brittle zone.

This actually might be a good thing in the handle to blade intersection.

Heating the metal to 800F might just make the blade less brittle in that area.

A lesson I learned a long time ago

Back in the 1980's I was working in a fab shop.

There was a safety audit that cited gas cylinders not being stored securely so the shop foreman gave me a sack of bolts and told me to weld them to some flat bar so that the cylinders could be chained up.

So after tack welding a few of these bolts, I welded a couple of them out with a 7018 rod.

I went to chip the slag off and I accidentally bumped one of the bolts with the wood handle of my chipping hammer.

The bolt snapped off right at the weld...I barely grazed it and it just snapped.

I had been handed some high carbon, high strength bolts.

I didnt think to check the bolts, or to ask about carbon content, I assumed if the foreman handed them to me, they must be ok.

That is a lesson I wont forget...and this "how to tig braze" video on this file brought the memory back.

Q & A about Silicon Bronze filler rod

What is silicon bronze used for in welding?

Silicon Bronze is often used for brazing plain or galvanized steel sheet metal. Due to its low melting point compared to steel, the process is technically brazing and not welding even though it is often referred to as welding. Silicon bronze filler rod can be used for either tig brazing or oxy fuel brazing. Silicon bronze filler rod can be used for joining any copper alloy to any other copper alloy as well as for joining dissimilar metals. Stainless steel, carbon steel, cast iron, and copper alloys can all be joined to each other using silicon bronze filler rod. But tensile strength of silicon bronze filler rod is often lower than the metal being joined so that is a consideration.

Silicon Bronze is also used for surfacing parts for wear resistance and also corrosion resistance .

What is the tensile strength of silicon bronze?

Different filler metal suppliers list the tensile strength of silicon bronze filler differently but ERCuSi-A grade is listed somewhere around 50,000 psi. This is often lower than the metal being joined so in the case of fillet welds, it is sometimes wise to make a much larger fillet.

What is the chemical composition of silicon bronze?

ERCuSi-A Silicon bronze is mostly copper but contains between 2.8 and 4% Silicon along with residual amounts of manganese, tin and zinc.

Fe 0.50, Zn 1.0, Sn 1.0 Al 0.01, Mn1.5, Si2.8-4.0, Pb0.02 , Cu Balance Other0.50

What is the melting point of silicon bronze ?

The melting point of ERCuSi-A grade silicon bronze filler rod is listed at 1866 F. Since the melting point of carbon steel is around 2700F, it is possible to use much less heat to join metals and this can prevent distortion in thinner sheet metals. Silicon bronze filler is often used to joint galvanized sheet metal due to lower distortion as well as maintaining the zinc coating.

Tips for how to tig braze

Both DC and AC currents can be used for tig brazing.

Silicon bronze filler can usually be done using DCEN with great results although sometimes AC produces a cleaner deposit.

For Aluminum Bronze, AC usually helps clean up the puddle.

Cleaning the filler metal with emery cloth and an acetone wipe can really help too. Scotch brite can also be used but some grades leave a residue so the acetone wipe should be thorough.

Pulse settings can help with overheating but are not necessary.

One of the biggest factors in multiple pass surfacing is allowing the part to cool between beads.