Harbor Freight Welding Spoon

I went to Harbor Freight today...All by myself because...

My wife simply does not appreciate the shopping experience.

So about once or twice a year, I have to go get my HF fix.

Sure, You

do have to be careful what you bring home from HarborFreight but if you are

careful, you can get some really good deals on certain tools.

Does Harbor Freight have any good Tools?

The first thing that jumped in my cart was a couple of Welding Spoons.

Whats a welding spoon you ask?

Its just a piece of copper welded or brazed to a steel handle.

So simple that I figured not much could go wrong with this tool.

A welding spoon is pretty much intended to be used for mig welding

holes in auto body panels where spot welds have been drilled out.

The

reason for the handle is so you can hold the welding spoon with one

hand, and prop a mig nozzle right next to the hole where the wire is

aimed right at the center of the hole ...at the copper backing... and

then, with the machine set low, a quick squeeze of the mig gun trigger

fills in the hole. With a bit a practice and trial and error of setting

the mig welder just right, it works great. Copper backing helps a

bunch for filling in holes on thin sheet metal.

For This weeks

video, I decided to use the welding spoon for tig welding some holes in

18ga stainless which is supposed to be .048" ( thats a little over 1mm

thick).

Tig Welding Stainless Steel holes with a Harbor Freight Welding Spoon

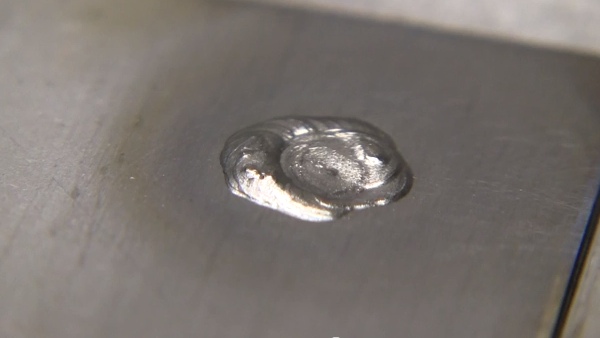

So in the interest of comparing how well the welding spoon works, I decided to weld one hole without any backing... one using the welding spoon...and one using something called a backup box which is a small purge box that uses perforated copper to supply argon to the back side of things.

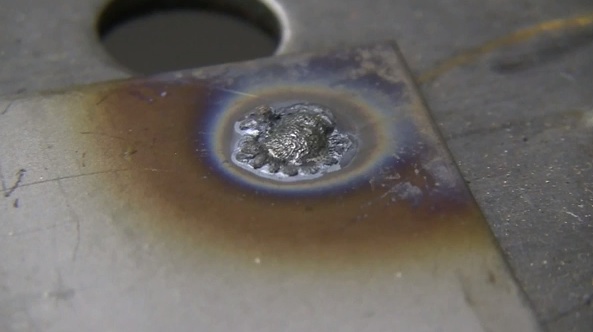

As expected, the hole that was welded with no backing sugared on the back side. Sugaring is a non standard term for "Granulation" which means molten stainless steel that has been severely oxidized.

Sugaring or Granulation is never a good condition no matter how you look at it.

For structural applications, its a stress riser and a place for corrosion to start. For the food service industry, its a place for bacteria to breed, And for pharmaceutical applications like valves, tanks and piping, its a nightmare....a lawsuit waiting to happen.

Copper backing is not always an acceptable way to weld stainless steel but it is 10 times better than using nothing.

For tig welding holes in carbon steel, it helps speed things up, makes for a better looking weld, and minimizes distortion. There really is no drawback.

Copper backing also works wonders for backing up the inside of an outside corner joint in stainless steel.

Oh yeah, and the next best thing to a copper block for backing is a thick piece of aluminum. Works almost as well.

I save every bit and piece of copper I can get because it really comes in handy. Copper pieces can be softened up by heating to cherry red and then quenching in water. Then you can bend and shape to fit right against the back side of a weld.

I also keep lots of blocks of thick aluminum around to use for backing and also for chill blocks on stainless sheet metal jobs.

But dont take my word for it. This is something you can prove out yourself with a small block of aluminum or copper and some thin sheet metal.

A word of caution,....even a little bit of welding time with heat up your aluminum or copper backing so make sure to handle it with care.

Sugaring / Granulation vs properly shielded back side of Stainless steel

So I am extremely happy with my new welding spoons.

I will probably use them more for tig welding but I will try to post a video filling holes with a mig welder soon too.