How to Get the most out of your Stubby Gas Lens kit

If you are still using the standard TIG cups and hardware that came with your machine or TIG torch, I can just about guarantee you will get better results if you upgrade to a weldmonger® stubby gas lens kit.

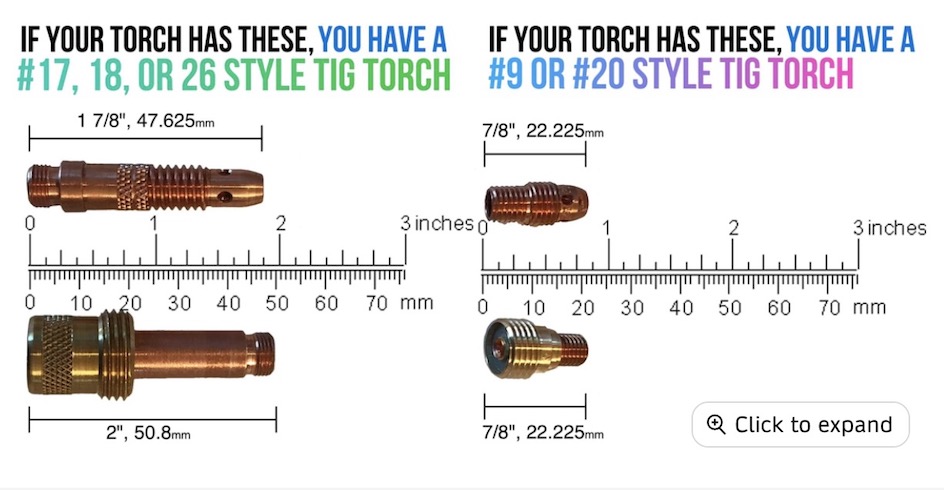

Make sure you know what type of TIG torch you have

- HOME

- TIG WELDING

- Stubby Gas Lens Kit

Know how to install all the hardware correctly

What size cup to use? scroll down

What flow rates do I use for each size cup? scroll down

What size tungsten is best for what I am welding? If you have a 200 amp tig welder, a 3/32" 2% lanthanated tungsten will handle pretty much everything a 200 amp tig welder can do. And you might find that makes life easier to just leave a 3/32" tungsten in your torch all the time.

If you have more amps to play with, a 1/8" tungsten might be a good choice.

If you find yourself tig welding a lot of thin metal for long periods of time, a 1/16" tungsten is much easier to sharpen, costs less, and can provide crisper arc starts at low amps.

how far should I extend my tungsten? as a rule of thumb, try not to extend your tungsten any further than the inside diameter of your tig cup. Example: cups are sized by 16ths of an inch so a #8 cup is 1/2" inch and that is a good maximum stickout distance for a #8 cup.

There are always exceptions but that is a good rule of thumb.

what filler metal should I use? there are filler metal charts for aluminum and stainless steels to guide you on filler metal selection but for low carbon steel, ER70S-6 from weldmonger.com works great.

how long should I set my post flow gas?

Post flow gas is the time shielding gas continues to flow after the arc is stopped. Too much post flow wastes gas and too little oxidizes the tungsten. 7 seconds is a good minimum but if you are welding stainless, chromoly, nickel, or other steel, more post flow is needed....and for Titanium, Sometimes the maximum your machine setting allows is needed along with a pedal bump to continue the post flow is sometimes needed to prevent oxidation.

What is pre flow and what is the best setting for pre flow?

pre flow is to get argon flowing before the arc to provide a clean arc start. for most steels, .5 second is plenty. But for aluminum a full 1.5 seconds can help with clean arc starts.

Are there other cups I should add to my stubby gas lens kit for best results?

If you need really good shielding for stainless, nickel, 4130 chromoly, tool steels, etc. along with the ability to use a long electrode extension, a ceramic jazzy10 and a ceramic 12 furick cup are great addition to the weldmonger stubby gas lens cup.

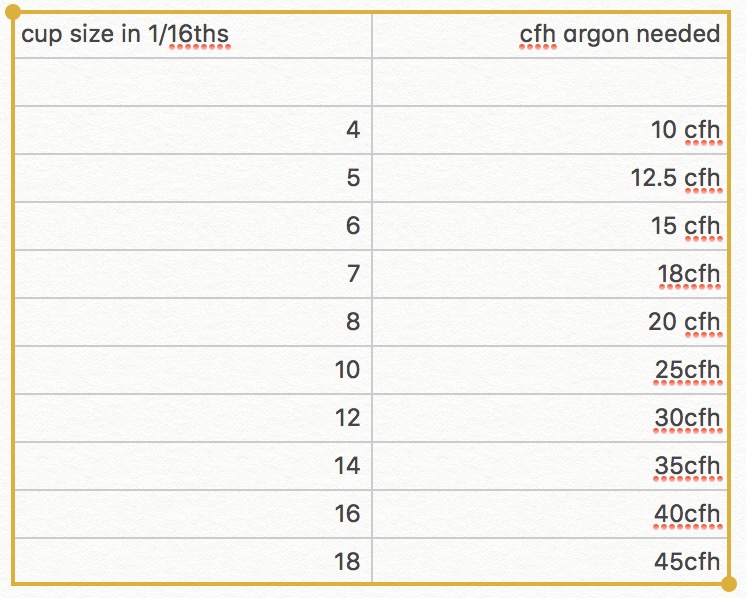

What size cup is best for what? and What argon flow rates do I need for each size cup.

Argon Flow rates for each Cup size using 2.5 as factor

Each welding task brings unique challenges so there are no hard and fast rules for cup size.

But here are some guidelines that will help:

Argon flow rates are largely determined by the size cup you are using and as a rule of thumb, it takes 2 to 3 CFH of argon flow for best results.

So a #4 stubby gas lens cup needs 8-12 CFH while a #12 cup needs 24-36 cfh.

I like to use a #4 for thin aluminum fillet welds and for speed tack welding to save argon.

A #5 stubby gas lens cup is a favorite for a lot of really good tig welders I know for aluminum up to around 1/8" (3.2mm) thickness.

A #6 stubby gas lens cup is a great all around cup for aluminum. Especially if you like to use a #5 but need to jump up to a larger electrode like a 1/8" (3.2mm) because a 1/8" tungsten really fills up a #5 cup too much.

A #7 gas lens cup is a good all around size for carbon steel, stainless, and aluminum.

A #8 stubby gas lens is the largest size I typically use for aluminum but works great for all around welding of steels.

Our Weldmonger Stubby Gas lens kits come with furick gas lenses and furick wedge collets that are much higher quality than other kits.

Having the furick gas lens collet bodies with o ring grooves lets you build on this kit without needing to buy adapter kits for clear cups