Gas Metal Arc Welding - How to Mig Weld an open butt root downhill and weave uphill

( ... having trouble viewing this video? click here to view it at Welding-TV.com. )

Gas Metal Arc Welding is more commonly called MIG welding and is great for welding downhill when there is a gap.

Thats why open butt root passes go so well with mig welding. The puddle chases you down and once you do a few root passes, its as easy as falling off a log.

If you need to practice laying open butt root passes and you dont have access to lots of beveled plates, the next best thing is to use corner joints with gaps as shown in the video.

It really is very close to the real thing and I have used this joint for years to prepare students for an open butt V groove welding test.

3/16" hot rolled 2" bar stock is a lot cheaper than 3/8" beveled plates and works just about as well for practicing downhill roots.

Here are the main tips for gas metal arc welding (Mig welding) a root pass in an open butt V groove weld or practice corner joint with a gap:

• Keep the arc on the front of the puddle but not so far as to shoot wire thru.

• maintain consistent gun angle all the way

• KYSS - keep your stickout short

• pay close attention to fitup and get the gap right

Vertical Uphill Welding with Mig (gmaw)

Once the root pass is done, there is more practice to get out of this joint.

It is really good practice to weld an uphill weave bead over top of the root pass that was welded downhill.

One mig welding technique I like is to trace the leading edge of the puddle.

What do I mean by that?

The video demonstrates better than I can in words but basically what I mean by tracing the front of the puddle is to move the arc back and forth tracing the rainbow shape in front of the puddle.

This keeps the arc on the business end of the puddle and also gives a good technique for getting uniformity in your uphill vertical mig welds.

Gas metal Arc Welding uphill or downhill can result in cold welds that are not penetrated if the wrong settings or techniques are used.

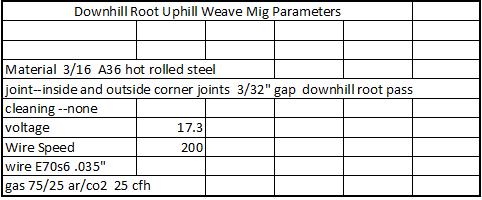

For 3/16" thick steel, here are the settings used in the video...

Support WeldingTipsandTricks.com and buy a T Shirt...click the shirts to learn more

exit gas metal arc welding and see the t shirts