Gas Metal Arc Welding Tests

Gas metal arc welding (gmaw) MIG TRIAL - PENETRATION vs WIRE SPEED AND VOLTAGE

Martin Rubenstein from the UK sent this detailed mig welding report.... I thought it was too good not to share.

Here is the summary...

8 sets of Test welds were done at 22 volts and 26 volts with different wire feed speeds. and using Coogar 5 gas. = 93% argon 5% co2 2% oxygen

Google seems to think the correct spelling is Cougar 5 but Air Products confirms the correct spelling is Coogar 5.

The mix for Coogar 5 is: 5% Co2, 2% 02 and 93% Argon Ferromaxx 7 is: 7% Co2, 2.5% 02 and 90.5% Argon

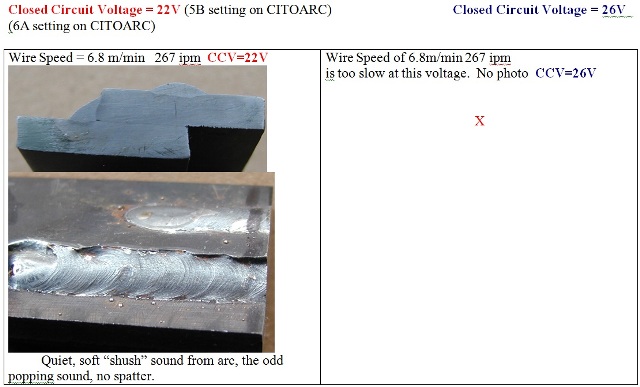

gas metal arc welding test #1 shows a lap joint fillet and a plain weld bead welded at 22volts closed circuit (under load) and Wire Speed = 6.8 m/min 267 ipm

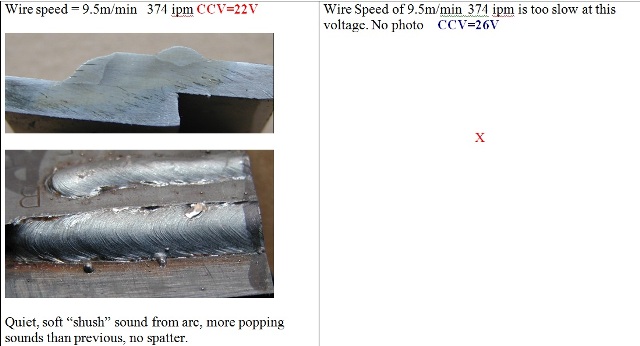

gas metal arc welding test #2 Lap joint fillet and a plain weld bead welded at 22volts closed circuit voltage (under load) and with Wire speed = 9.5m/min 374 ipm

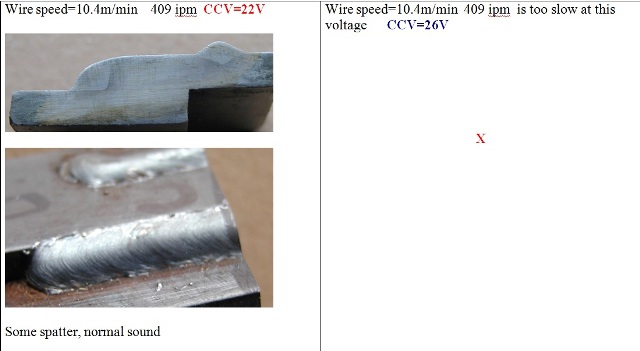

gas metal arc welding test # 3 Lap joint fillet and a plain weld bead welded at 22volts closed circuit voltage (under load) and with Wire speed =10.4m/min 409 ipm

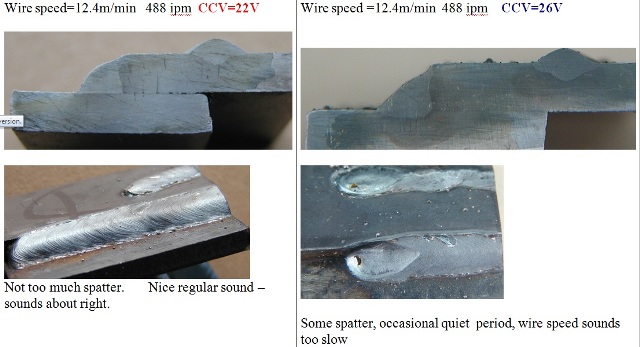

gas metal arc welding test #4 The photo below shows lap joint fillets and plain weld beads welded at 22volts and 26 volts closed circuit voltage (under load) and with Wire speed =12.4m/min 488 ipm

gmaw Test weld #5 below shows lap joint fillets and plain weld beads welded at 22volts and 26 volts closed circuit voltage (under load) and with Wire speed =13.7m/min 539 ipm

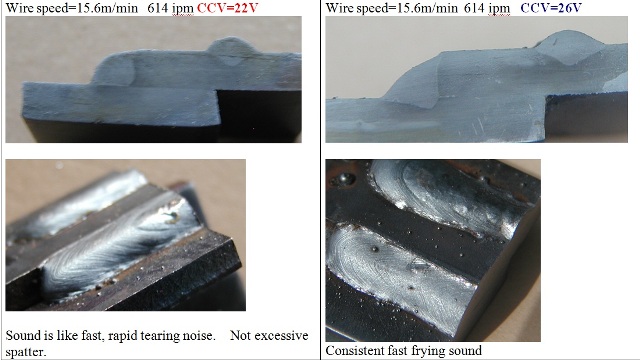

test weld #6 The photo below shows lap joint fillets and plain weld beads welded at 22volts and 26 volts closed circuit voltage (under load) and with Wire speed=15.6m/min 614 ipm

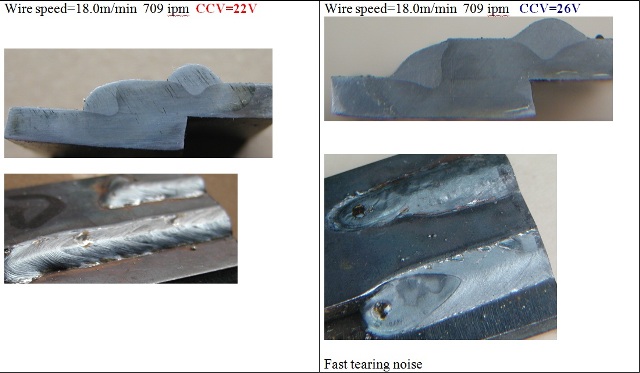

#7 Lap joint fillets and plain weld beads welded at 22volts and 26 volts closed circuit voltage (under load) and with Wire speed =18.0m/min 709 ipm

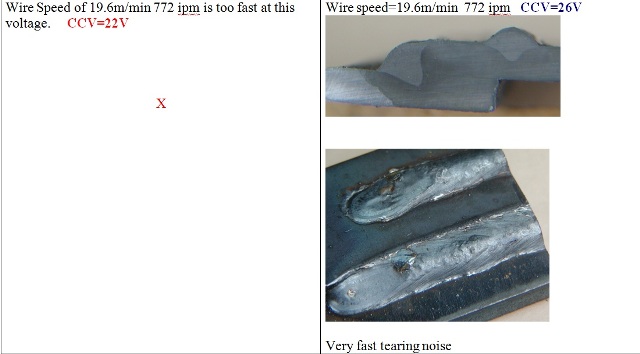

gmaw test weld #8 below shows a lap joint fillet and a plain weld bead welded at 26 volts closed circuit (under load) and Wire Speed = 19.6m/min 772 ipm

Wire speeds are listed on the images below in meters per minute as well as inches per minute.

The welds were cross sectioned polished and etched. The weld penetration is plainly shown.

here are the conclusions of the Mr Rubenstein after running the test...

"I did some trials recently at college - MIG penetration vs voltage and wire speed, to help me understand things better. "

1. There isn't necessarily a right or wrong wire speed for a given voltage. Penetration increases with wire speed - no real surprises there. (That's not to say that the "frying bacon" wire speed may well be best for other reasons eg spatter, appearance. etc) (And, obviously, wire speed could be too slow or fast to get a decent bead.)

2. You can get good MIG welds over a much greater wire-speed range (for a given voltage) than I had thought.

3. Penetration increases with voltage (again, no surprise); however, a small change in voltage has considerably more effect on penetration than a small change in wire speed.

4. For good penetration (ie always!) set the voltage high and adjust the wire speed to suit (which is what your most recent video is all about).

5. The voltage setting is more critical for a good MIG weld than is the wire speed (which is not to downplay the importance of current/wire speed, of course, but what I have realsied is that I shouldn't worry too much about listening for the right sound; I should concentrate on getting the voltage right, first and foremost).

a. 0.8mm / .030" dia wire

b. Cougar 5 gas = 5% co2 2% oxygen and 93% argon

c. 6mm .240" mild steel plate lap joint in horizontal –vertical position

d. Stringer bead on top plate included to show penetration

e. Open circuit voltage on CITOARC is considerably higher than operating, closed circuit voltage (CCV)

f. Trial conducted in dip transfer mode at 2 CCVs (22V and 26V, corresponding to 5B and 6A voltage settings)

g. Slope angle approx 45 degree, aimed into corner, tilt angle approx 75~80 degree, stickout short approx 3/8”

exit gas metal arc welding tests and see mig welding tests for uphill welding