Furick #7 Clear Cup on Thick aluminum

Brad Goodman gives a demonstration on how he pulses with the foot pedal for that stacked dimes look. Brad builds dog boxes, dog feeders, and does a lot of welding for motorsports teams. His customers want the stacked dimes look.

In the video above, Brad uses a Furick #7 clear cup at over 270 amps to test the cups amperage rating

TIG Welding Aluminum Corner Joint with a furick #7 clear cup - Andrew Cardin

Michael Furick has a brand new cup and its pretty sweet!

It's the clear #7 furick cup and its a great all around gas lens cup for TIG welding both aluminum and steels.

The Furick 7 clear cup is rated at 200 amps but that is a very conservative rating.

The reason I know is that I tested it by welding several beads on a thick piece of aluminum on a turntable at over 270 amps with no problems. ( video coming soon)

Here are a few tips that I learned while filming this short #7 cup video...

Argon flow rate and AC balance are related. The degree of cleaning action you get is not only influenced by the AC balance setting but also by the argon flow rate and cup size.

I will dig into this in the future but I did some testing while filming this video and the results were very enlightening.

Once I got the flow rate optimized, I started using a newly sharpened tungsten on every restart.

That really made a difference on arc starts...they got better.

How Argon shielding is related to AC balance and cleaning action while using a furick #7 clear cup

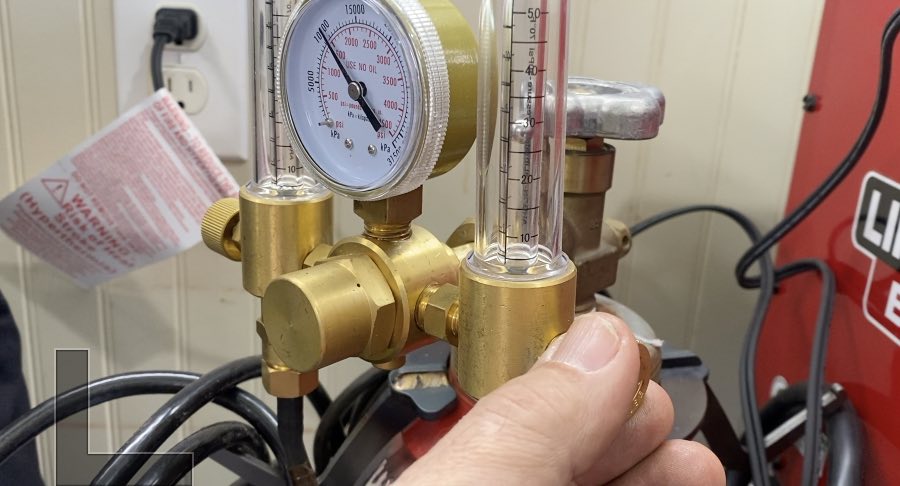

Argon flow rates are largely determined by the size of the cup and a good rule of thumb for flow rates is 2 to 3 cfh per cup size.

So for example, for a #7 cup, that would be 14-21 cfh.

Sometimes that rule of thumb works and gets you right in the ball park.

But while we were making this video, we noticed something off at 20 cfh.

We were not getting as much cleaning action as we expected.

So we increased the flow rate to 25cfh and the cleaning action improved but not quite to our liking.

so we bumped it up to 30 cfh and the puddle got cleaner, and we could see a wider etching band at the toes of the weld.

All this without touching the AC balance setting.

So we learned that the cleaning action of the AC arc needs an argon shielded area in order to work best.

Cleaning action does not like to go where there is no argon.

So for every cup size, every joint type, there is a sweet spot of argon flow rate.

Dont be afraid to adjust argon flow if you are not getting the results you want.

Technical stuff about argon shielding

When TIG welding aluminum, the argon shielding gas serves two main purposes:

- Shielding the weld pool: By surrounding the weld area with a flow of argon gas, it displaces the surrounding air and prevents oxygen from coming into contact with the molten aluminum metal. This shielding effect helps to minimize oxidation and ensures a clean, high-quality weld.

- Protecting the tungsten electrode: Even though it is said in many technical documents that TIG welding uses a "non consumable" Tungsten electrode to provide the arc, the tungsten sometimes still gets consumed by accident. When the tip of the tungsten gets crapped up by filler metal or by oxidation, it needs to be reground.

Argon gas shields the tungsten from oxidation while welding and while the tungsten is cooling off after the arc is terminated. That is why you need to have your post flow setting at least high enough to shield the tungsten and keep it silver. If you move the hot tungsten too quickly after a weld and the tungsten turns grey or purple, that is severe oxidation and when you restart the weld, that oxidation out-gasses and contaminates the weld area and causes those brown or black sooty clouds and introduces oxides into the puddle.

If you really need the best and crisp restarts , regrinding or replacing the tungsten electrode with a newly prepped one for every restart will make a difference.