Dual Shield Flux Core Welding vs Short Circuit Mig on a Vertical uphill Tee Joint

see more videos on dual shield flux core

3g and 4g plate test with Andrew Cardin

I visited JD Brewers shop for this video where we used 2 ESAB Rebel 285 machines to compare vertical uphill welding.

On one Rebel machine we used .035" Esab 7100 dual shield wire...

and on the other, .035" ER70s-6 bare wire.

C25 gas was used for both welds (75/25 argon/co2)

Usually, JD would use .045" or larger dualshield wire for 1/4" thick metal but we wanted to keep wire diameter the same for this test.

But the smaller .035" size wire does come in handy sometimes.

JD routinely uses .035" wire in the field where he welds with a small inverter mig welder powered by a generator. ( up until now, he used a lincoln powermig 210mp but soon we will try out the new REBEL 215 for that type of work)

.035" wire works really well for pipe welds where the root and hot pass are done with TIG and the fill and cap are done with dualshield flux core welding. video of pipe welding with JD tig root and flux core fill

for the shop, he usually uses .045" gas shielded flux core wire for the increased travel speed range it provides.

Dual Shield penetrates mill scale

JD uses dualshield flux core to build and repair mezzanines, handrails, hoppers, stairs, platforms, racks, and many other items made from square tubing, pipe, angle, and plate.

A lot of the shapes have a very light mill scale coating.

With dual shield flux core, JD finds that he is able to penetrate thru light mill scale easily without leaving undercut and without compromising weld quality.

And not having to grind mill scale translates into time saved and more money made per hour.

Manipulation of arc to control the puddle

In this video, it is plain to see that I was using quite a lot of gun manipulation in order to help the weld lay down flatter.

With short circuit mig, this seems to be necessary. At least for me it is.

But with dualshield flux core, the flux helps the molten puddle to solidify in such a way that no real manipulation or oscillation of the gun is needed in order to deposit a smooth flat weld in the vertical position.

(This is especially a benefit when teaching a helper to weld out o position.)

But mainly, the benefit is increased travel speed on vertical welds without over welding.

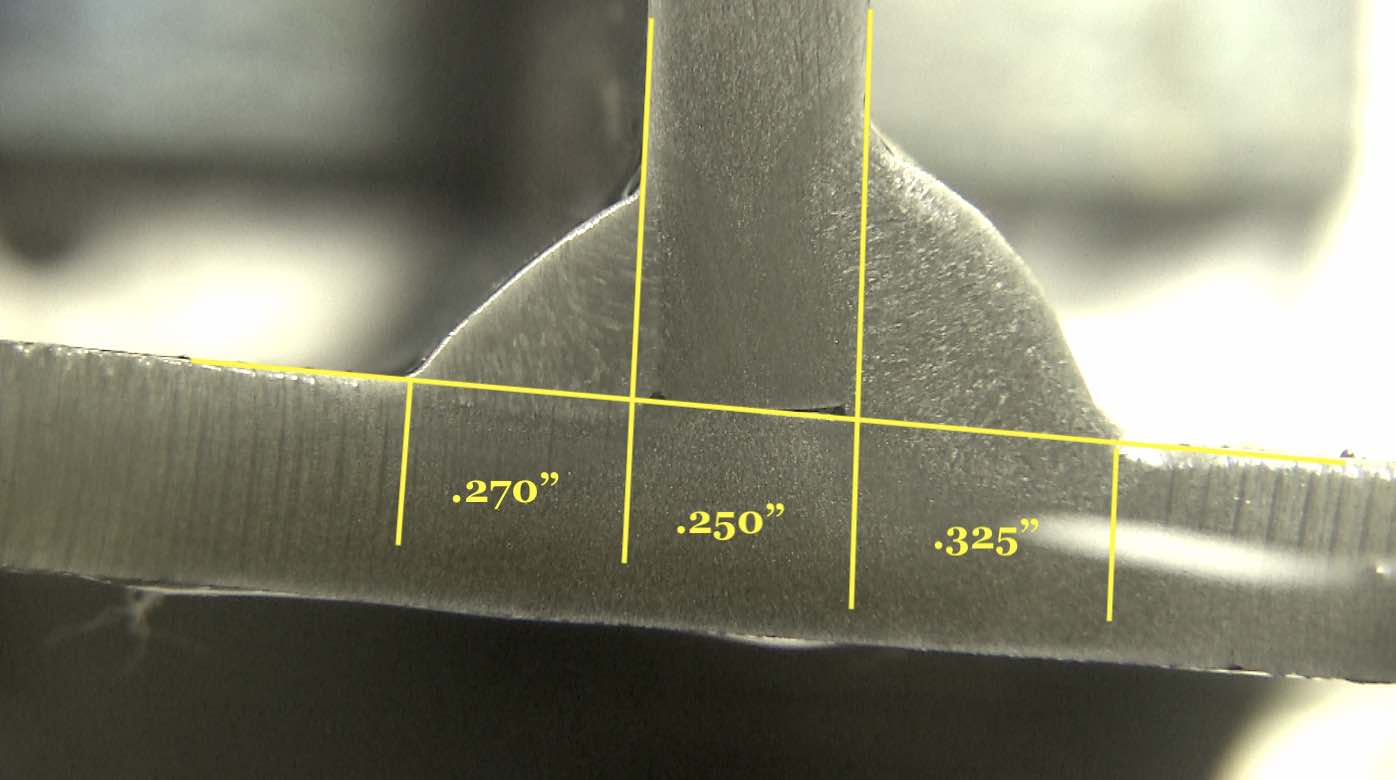

The short circuit mig weld was essentially over welded due to the fact that a minimum fillet weld size for 1/4" thick steel would typically be around 3/16"...sometimes even less.

The dual-shield weld measured .270" while the short circuit weld measured .325"

I have no doubt both welds are sound welds, but one just took longer and wasted more gas and filler metal in depositing more weld than was required.

Esab Dual Shield Welding guide pdf