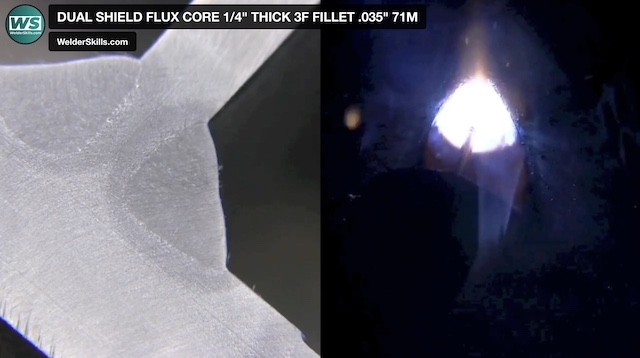

DUAL SHIELD FLUX CORE 1/4" THICK 3F FILLET .035" 71M

scroll down for settings

- HOME

- Mig Welder Settings

- Dual Shield

- Dual Shield

WELD PROCESS = DUAL SHIELD FLUX CORE

VOLTAGE= 23.5

WIRE FEED 370 IPM

METAL TYPE = CARBON STEEL

THICKNESS = 3/16"

WELD TYPE = Fillet weld

JOINT TYPE = tee

POSITION = 3f vertical

FILLER WIRE = .035" lincoln 71M

POLARITY = DCEP

GAS FLOW = 35 CFH 75/25 (c25)

VOLTAGE AND WIRE SPEED WILL VARY SLIGHTLY FROM MACHINE TO MACHINE AND WITH DIFFERENT BRAND WIRES BUT 23.5 VOLTAGE AND 370 IPM WILL GET YOU IN THE BALL BARK FOR .035" DIAMETER DUAL SHIELD WIRE