Cutting Torch Oxy fuel Safety - Section 3. Understanding Acetylene and other Fuel Gases

1. What is the function of the fuel gas in an oxy fuel cutting torch process?

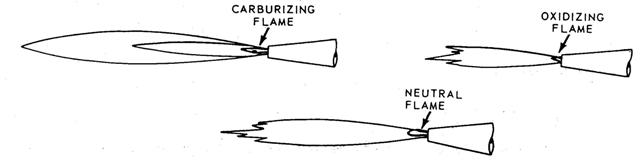

The first function of the fuel gas is to provide a medium for ignition. The second function is to combine with oxygen, typically adjusted to a neutral flame setting, and provides the heat to raise the temperature of the material to it’s kindling temperature.

2. There are several basic types of fuel gases. What are they and what are their respective temperatures (approximate), when mixed with oxygen to a neutral flame setting using a cutting torch?

a. Acetylene 6000 degrees F

b. MAPP 5400

c. propylene 5200

d. propane 5000

e. Natural gas 4800

The temperatures quoted here are only approximate.

Flame temperatures do not tell the whole story regarding differences between fuel gases. There are also different BTU delivery; oxygen mixing ratios; rate of burn; and, differences in the temperature and BTU on different parts of the flame.

Acetylene is still one of the most commonly used fuel gases for a cutting torch as well as for heating.

Soldering, brazing and welding are also done with acetylene. Acetylene contains the greatest amount of hydrocarbons. Acetylene produces the highest temperature of the commonly used fuel gases. It requires one part of oxygen mixed with one part of acetylene to achieve complete combustion of the fuel.

The inner cone of the acetylene flame is where the greatest amount of heat and BTU delivery will be obtained. The amount of heat delivery of the acetylene flame is 1,450 BTU/CF.

Acetylene will burn at the rate of 29 feet per second. One reason why knowing the burn rate, is in the design of cutting torch tips and heating tips.

Acetylene tips are typically straight or slightly concave at the tip face.

Alternate fuel tips are recessed at the tip face an increasing amount depending on the gas.

MAPP, propylene, propane and Natural gas are all considered ‘alternate fuels’.

There are several variations of these, depending on manufacturer.

MAPP contains less hydrocarbon than acetylene, but more than the other alternate fuels. When lit, it will produce a sooty flame, similar to acetylene.

For complete combustion, 2.5 parts of oxygen are required with one part MAPP. The greatest amount of heat is delivered in the secondary flame cone, of 1900 BTU/s. The MAPP flame produces a total of 2400 BTU’s/CF. Its burning rate is 15 feet per second. Cutting tips typically have a 1/32”recess in the tip face to provide for an efficient flame.

Propylene is the third class of fuel gas. It contains less hydrocarbon, so is a fairly clean gas. It requires 3.5 parts of oxygen mixed with one part propylene to obtain complete combustion.

It produces 2400 BTU’s/CF, with 2000 BTU’s delivered from the outer cone of the flame. It burns at a rate of 13.5 feet per second. Cutting tips designed for propylene have a 1/16” recess in the tip face.

Propane is a clean burning gas.

It requires 4 parts of oxygen, mixed with one part of propane to provide complete combustion of the fuel. It produces 2600 BTU’s CF, which is the most of the fuel gases, making it a popular choice for heating. Again, the outer or secondary cone of the flame is where most of the BTU’s are delivered.

Propane burns at the rate of 11.5 feet per second. Cutting tips designed for propane use will typically be recessed 3/32” in the tip face.

Natural gas is the cleanest burning gas of the common fuel gases (Hydrogen is cleaner). For complete combustion, 2.5 parts of oxygen are required, with one part Natural gas. It delivers a total of 1,050 BTU’s, with 1,000 delivered through the outer or secondary cone of the flame. The burning rate is 10 feet per second. Cutting tips designed for Natural gas are recessed the same as for propane, of 3/32”.

Ready for Section 4 - the burning process? see links below

• MAIN PAGE ON CUTTING TORCH OXY FUEL SAFETY

• SECTION 1. Understanding the fundamentals of combustion

• SECTION 2. Proper handling of compressed gas cylinders.

• SECTION 3. Oxy-Fuel gas characteristics

• SECTION 4. The burning process

• SECTION 5. Proper operation of oxy-fuel heating tips

• SECTION 6. Oxy-fuel Equipment inspection

• SECTION 7. Oxy fuel Safety torch - tips