Best Tungsten for Titanium

...Introducing the New WeldMonger Challenger TIG kit that includes the most frequently used Cups.

The Best tungsten for Titanium depends mostly on the thickness and type of weld.

There are several good choices like 2% ceriated, E3, LaYZr, and 2% thoriated, and 2% lanthanated can all do fine on titanium.

I personally use 2% lanthanated on most everything to keep life simple.

But if I were to be in a job where I welded titanium for extended periods I might choose something else that stays sharp longer on DCEN polarity.

Some titanium welds involve several restarts and since E3 and LaYZr tungsten both excel on restart consistency, both are a good choice for tig welding titanium.

The main 2 things you need out of a tungsten electrode for titanium welding are...

- ability to hold a sharp tip for a long time

- sure fire starts and restarts

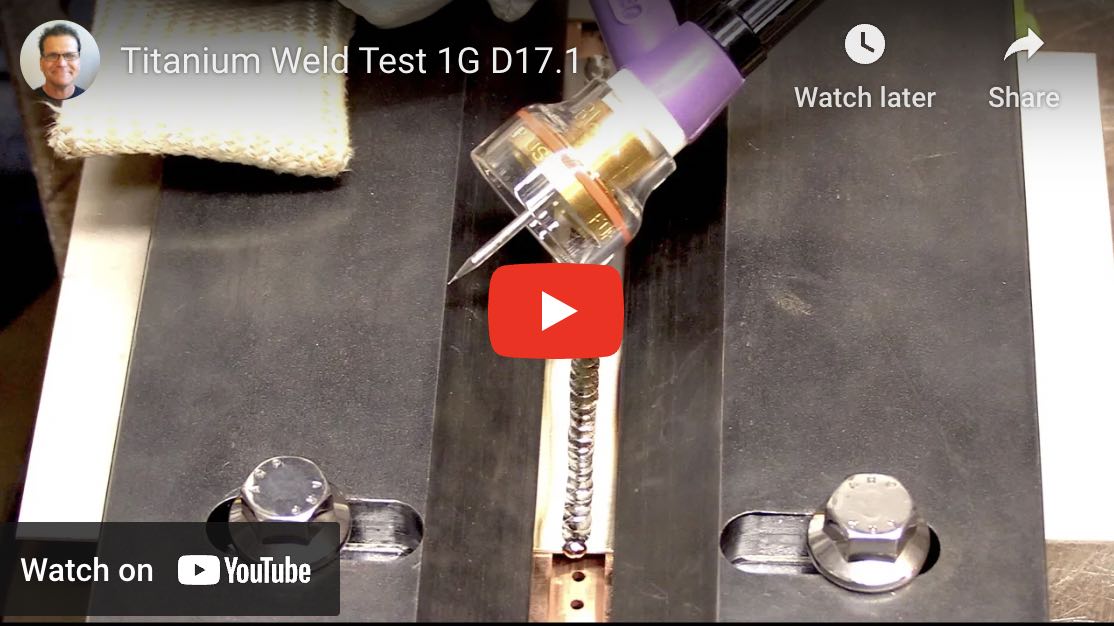

The 3 best tungsten electrodes with these 2 features are 2% thoriated (red), E3(purple), and LayZr (chartreuse) from ck worldwide in my opinion.

Since 2% thoriated has received a lot of bad press over the last 15 years or so concerning radioactive elements, E3 and LayZr might be a better choice.

But as far as performance goes, 2% thoriated is still one of the best tungsten electrodes for DC tig welding.

both LayZr and E3 tungsten electrodes can be a good choice for TIG welding titanium due to their unique properties. Here's why they might be suitable:

1. Improved Arc Stability : E3 and LayZr tungsten electrodes are known for providing a very stable arc, which is important when welding titanium to prevent contamination and ensure clean welds.

2. Enhanced Longevity : E3 and LayZr tungsten electrodes typically have a longer lifespan compared to some traditional tungsten electrodes, reducing the need for frequent replacements and maintaining consistent weld quality.

3. Low Contamination :E3 and LayZr tungsten electrodes both have low contamination risk, which is important when welding reactive metals like titanium.

4. Versatility : E3 and LayZr tungsten electrodes are effective for both AC and DC welding, making them versatile for various applications and types of welding machines.

While there are several choices that will work fine for most titanium tig welding applications, E3 and LayZr tungsten electrodes can also be an excellent choice for TIG welding titanium, offering similar benefits in terms of staying sharp, arc stability, longevity, and low contamination risk.