What is the Best all around tungsten electrode?

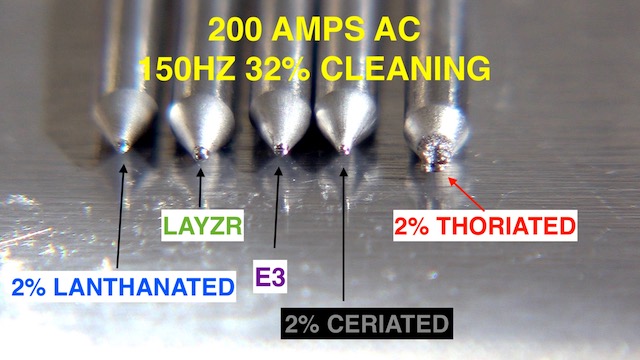

2% lanthanated, LayZr, E3, 2% ceriated, 2% thoriated?

- HOME

- TIG WELDING

- Best All Around Tungsten

If you are going to TIG weld, you need to know a little something about tungsten electrodes.

Back when I was first learning to tig weld, there were basically only 2 choices of tungsten you could get at a local welding supply.

( I was at my local welding supply a week ago and guess what? That’s all they had on display 2% thoriated and pure)

Carbon Steels and Stainless steels were welded with 2% thoriated tungsten and using DC current (direct current electrode negative)

Aluminum was welded using 100% pure tungsten on AC ( alternating current)

Times sure have changed.

Now there are several other different types of tungsten to choose from.

It can be confusing.

Fortunately, there are a few types of tungsten that work well for all metals and on both AC and DC.

E3, LayZr, 2% ceriated, and 2% lanthanated are all good all around tungsten that work well on both DC and AC.

My personal preference for an all around best tungsten is 2% lanthanated.

I use it for everything.

But that is just me because I bounce around from aluminum, to carbon, to stainless, to titanium.

Here is my 2 cents on the 4 best all around tungsten electrodes

2% ceriated - if you weld mostly carbon steel, chromoly, or stainless and only occasionally weld aluminum, then 2% ceriated might be a good choice because ceriated maintains a sharp point well on DC.

E3 and LayZr - These both seem to perform identically. Good low amp arc starts and low tip erosion on aluminum at medium range amperage

2% lanthanated - Good low amp arc starts on both DC and AC and high amperage range on AC. Best all around tungsten in my opinion