What is Autogenous TIG Welding?

Autogenous TIG welding simply means "TIG Welding without filler metal."

The word "autogenous" is a five dollar word that doesn't exactly roll off the tongue but is a term any welding student or professional welder needs to know because it is used in technical manuals, welding procedure specifications, and in conversations with engineer types.

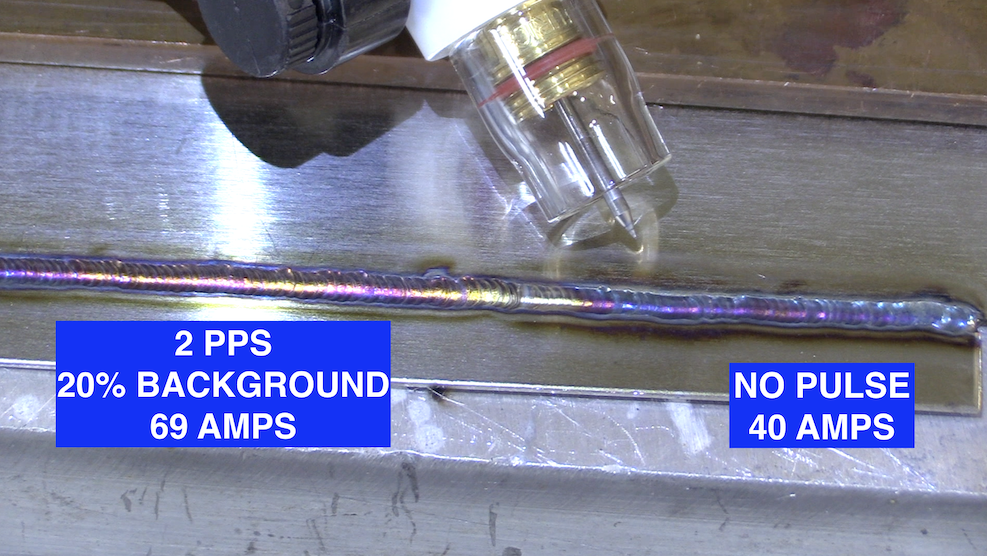

Autogenous TIG welding stainless steel lap joints with and without pulse settings

- HOME

- TIG WELDING

- Autogenous Tig

I welded half of a 16ga stainless steel lap joint without pulse at 40 amps and the second half was welded using 2 pulses per second (2pps) and 20% background at 69 amps.

I found the 2 pulses per second setting worked really well.

2 pulses per second is not that hard on the eyes and worked better than 1 pulse per second.

You might notice the second half with pulse settings was slightly less discolored than the first half where no pulse was used.

Not a huge difference...but a difference.

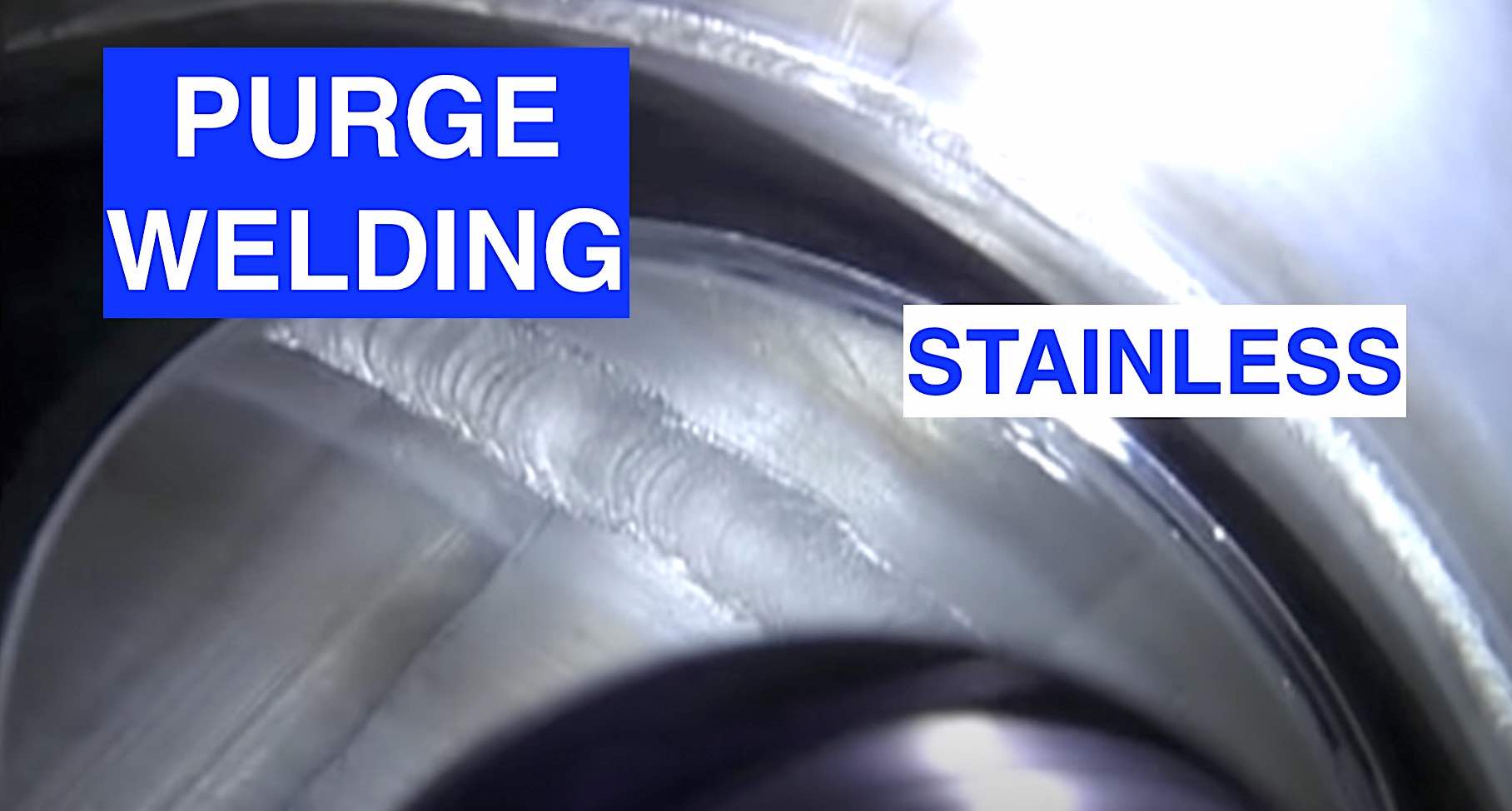

Sanitary Stainless tubing is another example of autogenous tig welding

Another example of autogenous welding is sanitary stainless tubing for breweries, hemp extraction, etc.

.063" wall thickness tubing is very common for sanitary tubing and usually no filler rod is used for a couple of reasons...

The most important thing about a sanitary stainless weld is the quality of the root pass.

A good purge is part of that.

Contaminants in the form of oxide islands are more likely to occur if filler metal is used and those oxide island deposits can trap bacteria.

18 ga outside corner autogenous weld

A third example of autogenous tig welding is 18 ga outside corner joint.

It can be a lot of trouble clamping chill bars for an 18 ga corner joint but its worth it to avoid distortion.

You can clamp them really close to the weld for best results in pulling out heat.

Pulse settings using a very low background current help too.

1.5 pps with 5% background along with chill bars worked great for 18 ga.