Arc Control Welding Setting explained in a short concise Video...

Scroll Down for Video

- HOME

- STICK WELDING

- Arc Control Welding

Arc Control - Arc Force - Settings guide

What does the Arc Control Welding Setting do?

Let’s break down what the Arc Control setting—also known as Arc Force or Dig—does on a stick welding (SMAW) machine and how to use it effectively.

What Is Arc Control / Arc Force / Dig?

When Arc length gets short, the rod has a tendency to stick.

maybe that is why they call it "Stick Welding"

Some machines have a setting that senses this drop in voltage and automatically bumps up amperage while the arc is short.

Arc Control, sometimes labeled as Arc Force or Dig, is a feature found on many stick welding machines (especially inverter and multi-process machines). It controls how much extra amperage is automatically added when the arc length gets very short—like when the electrode is close to the puddle or nearly touching the base metal.

Think of it as a "boost" to help prevent the rod from sticking when you dip too close.

- When you're welding and the arc length shortens (like during tight arc or deep keyhole welding), the voltage drops.

- Arc Control responds by momentarily increasing the amperage to prevent the rod from sticking and keep the arc alive.

- This extra amperage helps maintain penetration and arc stability.

Without enough arc force:

- The rod can stick to the workpiece.

- The arc may sputter or go out during tight root passes.

- You may have difficulty running rods like 6010 that require a forceful arc.

With too much arc force:

- The arc becomes violent or harsh.

- You may blow out the puddle or create excess spatter.

- Welds may become too convex or erratic.

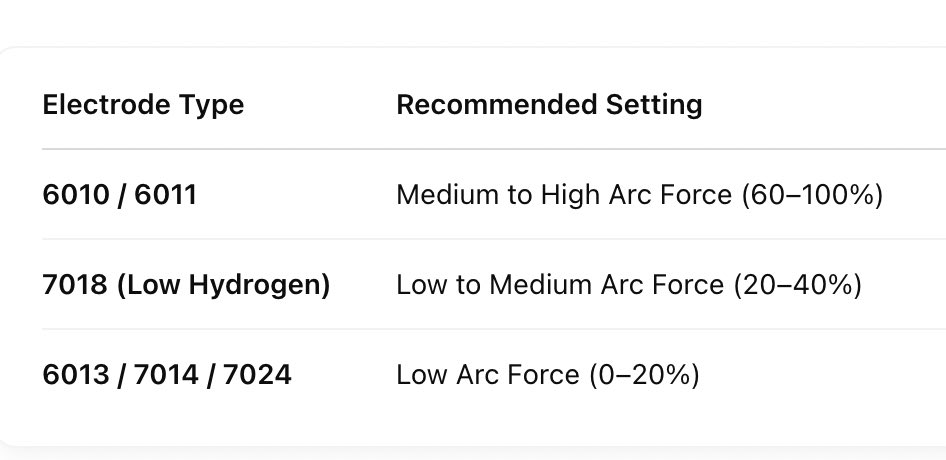

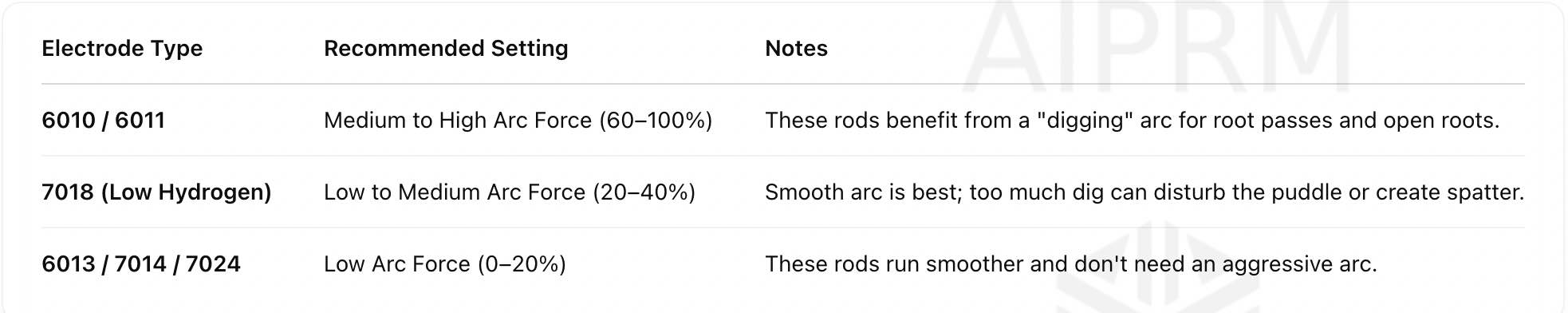

- Low Setting (0–20%): Soft arc, minimal digging. Good for thin metal or when a smooth bead is desired.

- Mid Setting (30–60%): Balanced arc. Great for most 7018 applications and general work.

- High Setting (70–100%): Aggressive arc for deep penetration, roots, and gap bridging. Best with 6010 or 6011.

How to Adjust arc control:

Start low and increase gradually until you get the arc performance you want.

✅ Pro Tips:

- On root passes with open gaps, increasing arc force helps keep the arc lit when you’re riding the keyhole.

- On fill or cap passes, too much arc force can make the arc harsh and unstable.

- It’s not a one-size-fits-all—tune it based on rod type, position, and base metal thickness.

watch more stick/arc welding videos

using "CLAMS" for welding

I know I am repeating myself here because I have already mentioned the term "CLAMS" many times as a way to remember the important things to help you get better at stick/arc welding.

But here goes anyway.

C stands for Current..thats amperage. As a general rule, you will want to set the machine amperage hot enough that the rod will not stick when you hold a tight arc length.

Current reminds us to check polarity as well os other settings like arc control and hot start.

L stands for Length of Arc. Hold a tight arc that is equal to electrode diameter or less.

A stands for Angle. Fortunately Stick welding is fairly forgiving on rod angle.

M stands for Manipulation of the electrode... there are lots of different rods and applications where some electrode manipulation is required. But welding flat or horizontal using a 7018 generally does not require any manipulation other than dragging it at the right speed...

S is for Speed...travel speed. rule of thumb is to travel slow enough to avoid undercut..but fast enough to avoid excessive build up.

Paying attention to these fundamentals of smaw will speed up the learning process

Welding machines and technology have changed quite a lot in the last 35 years.

But the fundamentals of welding have not.

These tips are just as good now as they were when I was in welding school.

visit the weldmonger store for DVDs, tig fingers, and much more.