Aerospace Welding test

A 2G aerospace welding test is not all that different from a flat 1G test.

...but X ray results often tell a different tale.

So here are a few tips to help you pass a 2G test for aerospace.

I used plain old 304L .063" stainless steel for this video but all the same tips apply to the other more commonly stainless alloys used for an aerospace welding test.

2 of the most commonly used stainless steels for aerospace tests are:

17-7ph and 15-7ph.

Both of these contain slight additions of aluminum to allow them to be heat treated and that makes them weld a lot more sluggish than 300 series stainless steels.

But, if you follow these tips, your chances of passing will be better.

(the jazzy 10 cup makes a big difference on aerospace alloys)

TIP #1...use the 3 C's Clean, Clean, Clean.

Wipe with acetone first to remove any oils, adhesives, or films.

then..

Use a clean dedicated file to clean the sheared edge of the tests pieces.

It might also help to use a fine abrasive disc like a silicon carbide 3m roloc disc ( I would not recommend scotch brite discs due to the polishing lubricant added)

TIP #2...Use a cup like the Jazzy #10 cup shown with around 25 cfh.

A 12 might even work better depending on the alloy

2.5 cfh argon per cup size will get you in the ball park but hey, this is a test so a few extra cfh will let you run a fairly long stickout and also gives you a very large area of argon to shield the hot tip of your filler rod.

TIP #3... use the minimum flow of purge gas that will still shield the back side.

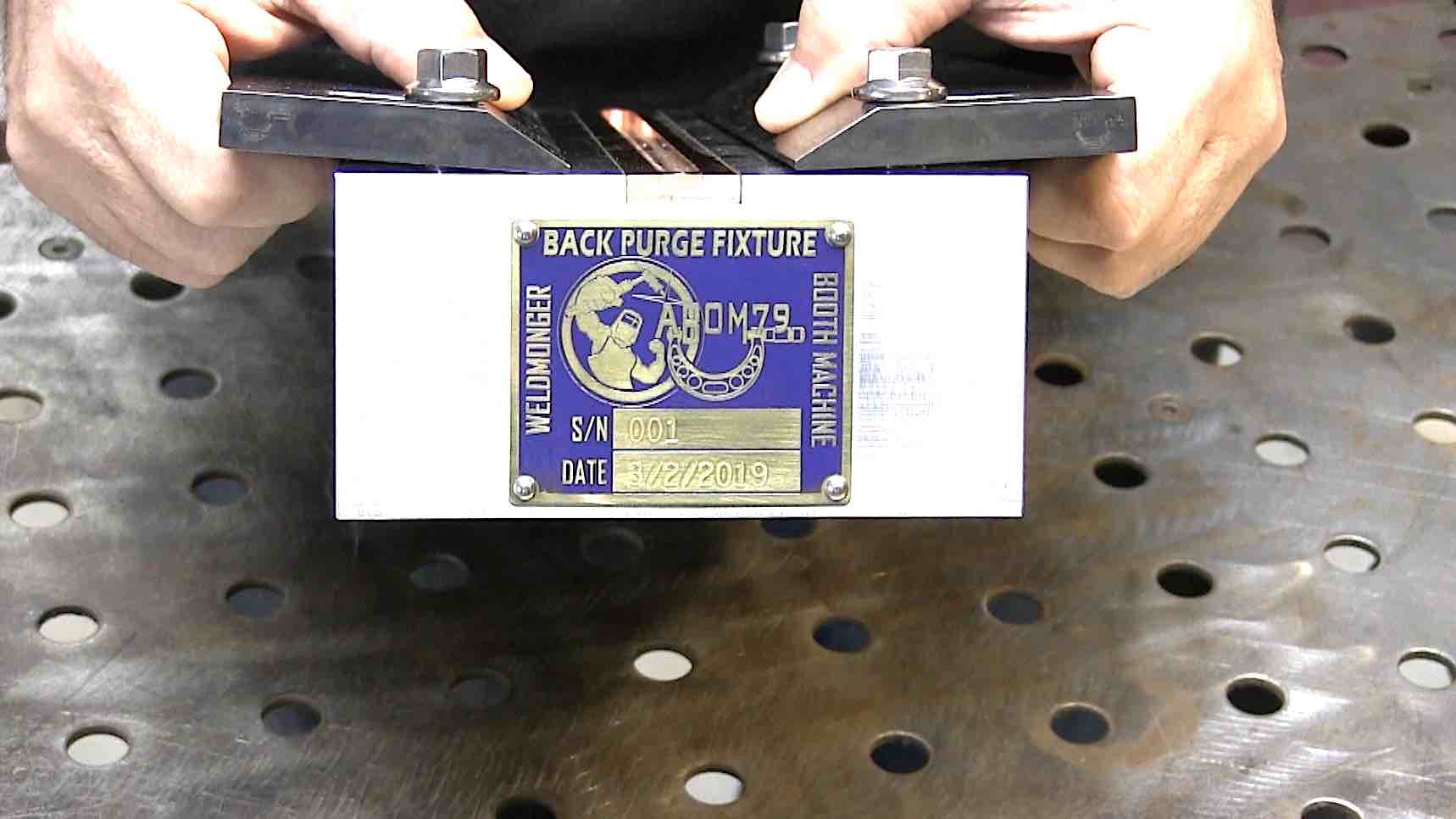

Most of the time, you will be testing on a fixture similar to the one shown here. ( seems to be an industry standard).

The purge holes and groove are usually pretty small and don't require much argon to get the job done.

Too much argon flow will disturb your cup gas on the ends and can even prevent smooth penetration on the back side.

Purge flow is like aspirin... enough is enough and more is not necessarily better.

You might even be provided a procedure on an aerospace welding test that gives a range for cfh of purge gas you will need to be within that range.

TIP #4...use an upward pointing electrode angle for 2G weld tests.

This one tip made a lot of difference in x ray results.

General tips:

I used a 3/32" 2% ceriated electrode for this practice joint.

A 1/16" tungsten would have easily done the job and might even be called out in a WPS (welding procedure specification)

If given a choice on filler wire diameter, I would choose as small a diameter as practical. Too large a filler wire chills the puddle quickly every time you add rod and that can cause porosity.