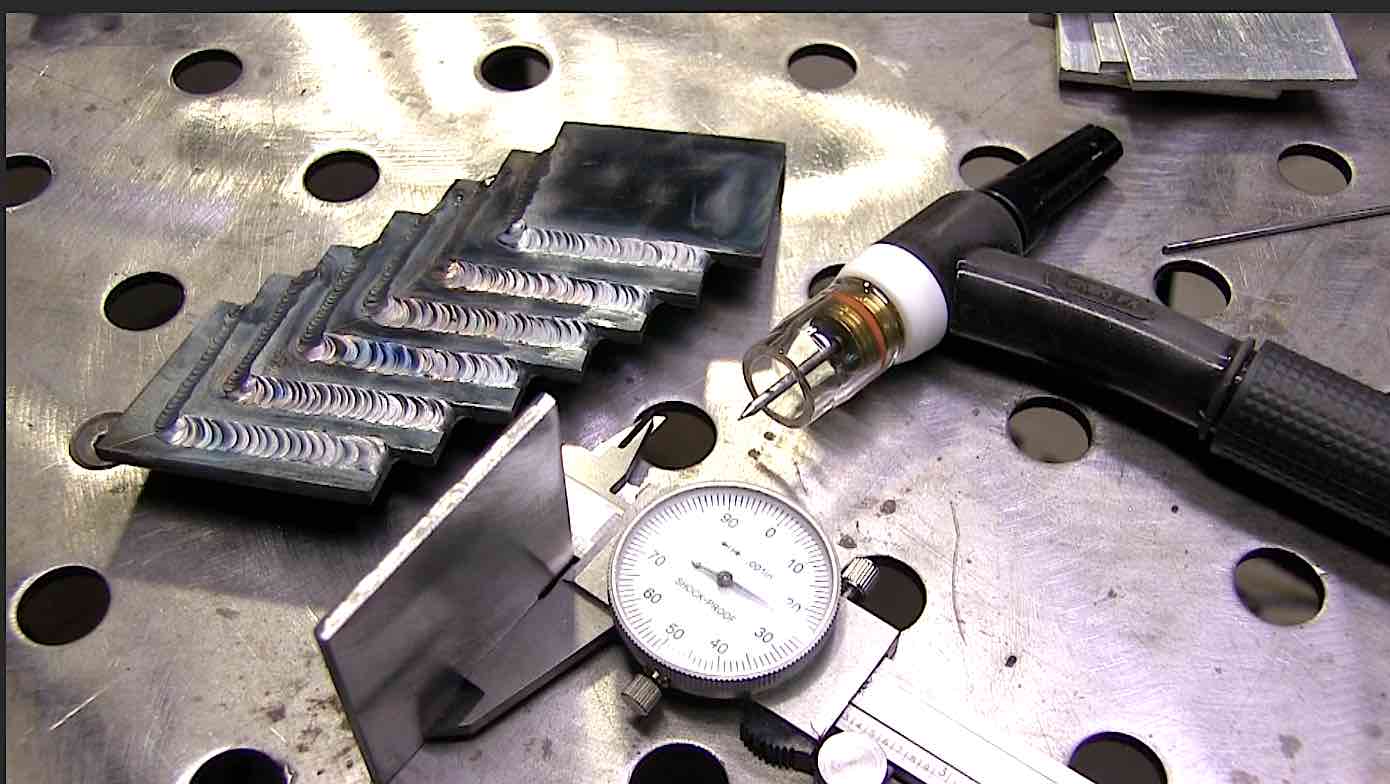

TIG Welding Lap Joints with a #8 Furick cup

click here or image below to learn more about the furick #8 cups

CK worldwide mt200 and a #8 furick cup= fun city.

I had some 2"x2" drops of cold rolled flat bar so I decided to get some tig welding practice on some lap joints.

The material was .125" (3.2mm) cold rolled steel.

I set the amperage to 120 and was pretty close to full pedal at times and topped out at 117 amps.

That just goes to show you the one amp per one thousandths of thickness is a pretty good rule of thumb for .125" and under.

click here to Check out the #8 furick cup at weldmonger.com

120 amps with foot pedal amperage control (117 amps max reached)

3/32" (2.4mm) 2% lanth electrode

1/16" (1.6mm) er70s-6 filler rod

I started out with a #6 gas lens, then switched to a #7 gas lens

using a stubby gas lens kit for the air cooled #17 CK torch

The #8 furick cup worked the best.

I used around 20cfh of argon with the #8 furick cup and was able to extend the electrode around 1/2" with no shielding problems.

I dont always extend the electrode that far but it makes filming easier.

Welding over severe oxidation

When you weld one side of something that is .125" or thinner, the back side will get oxidized unless you have some chill backing or argon shielding on the back side.

Welding over flakes of oxidation is no fun and usually winds up looking bad...or at least not as good as the weld done first.

So if you can clean it down to bright metal with some type of disc, abrasive, wire brush, or carbide burr, that removes the oxide layer completely, the metal will flow better and the weld usually looks a lot better.

Left hand practice

I dont do it often enough, but I try to remember to intentionally weld with my left hand when I am practicing.

Its a necessary skill that comes in really handy at times.

I dont need to use my left hand all that often since I am no longer welding pipe for a living but back when I did weld pipe every day, being able to weld with either hand was a big help.

I also think practicing with the non dominant hand gives you a different perspective and makes you think deeper about everything.

That is why I encourage anyone learning to weld, to use both hands early on in your training and practice.