7024 Electrodes

In this video I will be welding with some big stick rods

3/16” diameter 7024 rods also known as Jet rod…or Drag rods.

Toward the end of the video there is a quick summary of the more popular stick rods for low carbon steels.

6010, 6011, 6013, 7014, and 7018.

The "2" in 7024 electrodes means flat or horizontal only

7024 electrodes are also known as a drag rod. They are best used for laying down a lot of metal quickly.

The

2 in 7024 indicates these electrodes are rated for flat and horizontal

position fillet welds. Some manufacturers literature recommend single

pass fillet weds only but others state OK for multi pass fillet welds.

In

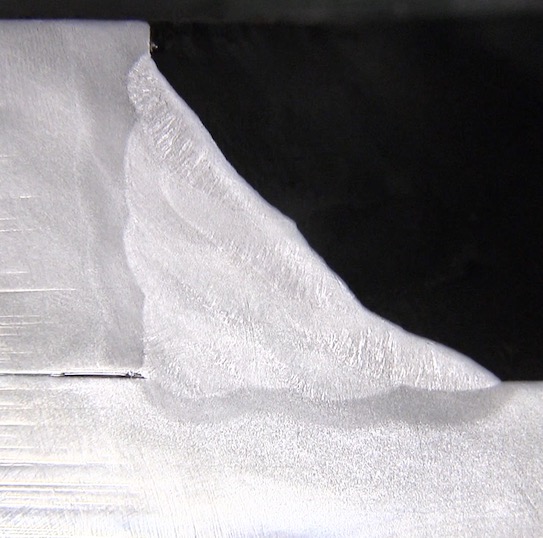

this video, I ran into issues on the upper half of a multi pass fillet

weld. The first bead welded great and looked smooth as glass.

The second bead looked pretty good but had a noticeable ridge in the center of the bead.

The

beads after that were more horizontal and less flat …even though

technically the lap joint welded is considered horizontal (2F) position.

Where high deposition rate is needed in 2f

fillet welds and other more productive processes like GMAW spray are not

feasible, and low hydrogen electrodes are not specified, 7024 is an

alternative.

Personally, I would much rather use a 7018 rod of the

same diameter and not deal with the issues of weird looking beads in

horizontal position where there was no metal to support the bottom of

the bead.

But for single pass fillet welds, that do not specify low hydrogen electrodes, a big 7024 works great.

6010 rods are classified as a fast freeze electrode and are used a lot for pipe welding. Especially for the root pass both uphill and downhill. 6010 can be used on DCEP and DCEN but typically won’t stay lit on AC.

A lot of smaller inverter type welders dont have the right type of power to weld with 6010.

Thats where 6011 rods come in.

6011 rods are a lot like 6010 but can also be used on AC. And most inverter machines that will not burn a 6010 can burn a 6011…some better that others.

6013 are classified as fill freeze electrode. 6013 electrodes can be used on DCEP, DCEn and AC.

They are easy to use and restart and can be used in all positions but they do have a heavy slag that can cause wormholes if incorrect angles or currents are used. 6013 rods have become known as “farmer rods” because of the ease of use and ability to use inexpensive AC buzz box welders.

7014 electrodes are also fill freeze and are similar to 6013 in arc characteristics but deposit more metal due to more iron powder in the flux. 7014 rods also run fine on AC as well as DC

7018 electrodes are classified as low hydrogen electrodes. Since hydrogen can cause cracking problems in thick steel ...especially high strength steel, 7018 rods have become a standard in structural welding.

In order to maintain the low hydrogen properties, 7018 rods must be kept new in box, or in a rod oven and there are limitations on how long they can be exposed to atmosphere before use.