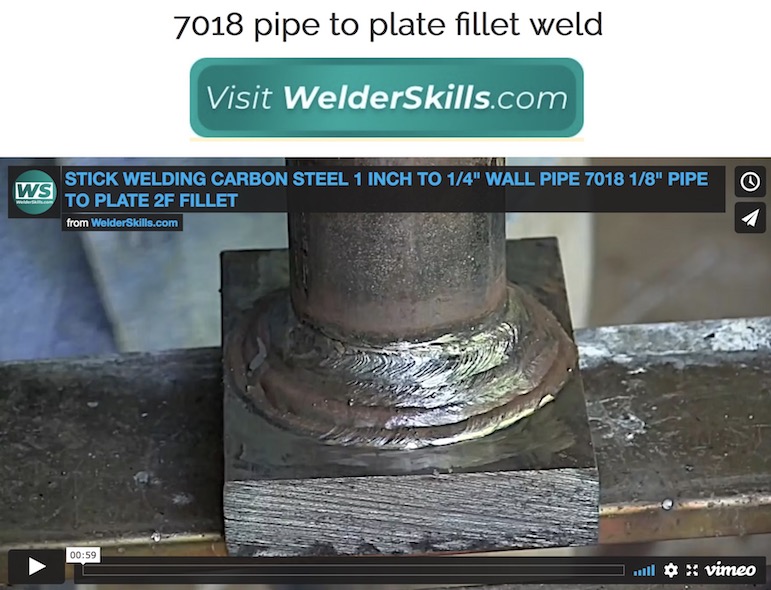

7018 pipe to plate fillet weld

For me, stick welding something that is round becomes much easier if I chuck up the rod at the right angle in the stinger. This lets me maintain a good angle just by turning my wrist

- HOME

- WELDER SETTINGS

- 7018 Pipe to Plate

WELD PROCESS = SMAW, SHIELDED METAL ARC WELDING, STICK WELDING

METAL TYPE = CARBON STEEL A36

THICKNESS = ONE INCH TO 1/4" WALL PIPE

WELD TYPE = Fillet weld MULTI PASS

JOINT TYPE = TUBE TO PLATE

POSITION = HORIZONTAL ON BENCH

AMPS = 140 AMPS

POLARITY = DCEP

ELECTRODE = 7018 1/8"" EXCALIBUR

ADDITIONAL SETTINGS =

TIPS: SET THE AMPERAGE HOT ENOUGH TO NOT STICK THE ROD WHEN YOU HOLD A TIGHT ARC… THEN HOLD A TIGHT ARC. DIFFERENT MANUFACTURERS ELECTRODES REQUIRE SLIGHTLY DIFFERENT AMPERAGE SETTINGS. USE AMPERAGE DEMONSTRATED TO GET YOU IN THE BALL PARK. TWEAK AMPS FROM THAT POINT AND ADJUST ARC CONTROL TO FIT THE SITUATION