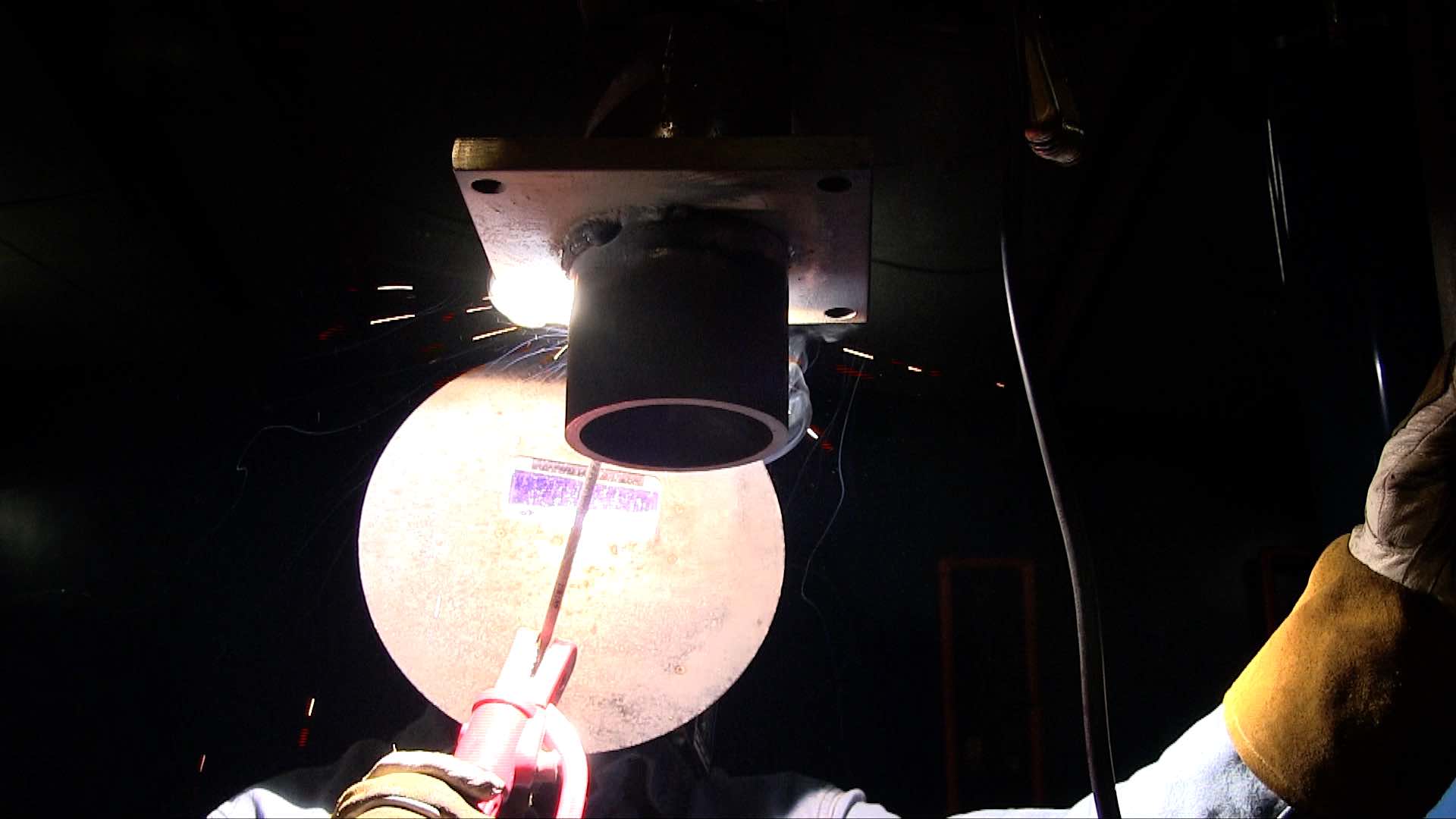

7018 Overhead Tube to Plate with 5/32" rod

If you searched for 7018 overhead tube to plate, you found the right place.

In this video, We welded Tube to Plate using 5/32" 7018 at 175 amps.

Here is the key to overhead stick welding with 7018...

Set the amperage high enough so that the rod will not stick even when you hold a really tight arc...

Then hold a tight arc.

175 amps on a lincoln 210mp with an arc force setting of 10 worked pretty well on this tube to plate 4f joint.

The same techniques used for an overhead tee joint will work for this overhead tube to plate joint.

The only real difference is that the part is round.

Pipe and tubing require body repositioning while welding and that is a skill that should be practiced.

The main things to consider when overhead stick welding with 7018 are:

- Amperage and Polarity...for this weld we used 175 amps on DCEP with arc force set to 10. (amperage range for 5/32" 7018 is 130-210)

- Arc Length was as tight as practical without sticking

- Rod Manipulation was minimal. The first pass was a drag pass. 2nd and 3rd pass seemed to go in better with some slight manipulation.

- Travel Speed was just slow enough to fill and avoid undercut

Why 5/32"?

The reason I chose to use 5/32" diameter electrodes for this video is that I have received several requests from welders who are being required to use 5/32" rods for field work as well as certification test welds.

5/32" 7018 can definitely be more efficient than 1/8" for certain situations.

It deposits more metal, less rods are needed, less restarts...you get the picture.

For efficiency sake, many contractors want the welder to use 5/32" 7018 instead of smaller rods where possible.

5/32" are pretty easy in flat and horizontal positions but are slightly more difficult for vertical and overhead.

main takeaways ...

Setting the amperage high enough but not too high. Too much amperage will cause arc blow and undercut.

Use minimal rod angle

Hold a tight arc

What is Undercut?

"an area melted into the base metal left unfilled adjacent to the weld toe or weld root ...left unfilled by weld metal"

In other words, an area where the arc melted away base metal and left it unfilled.

AWS D1.1 limits for undercut is 1/32" with some allowances depending on the length of undercut.

Undercut can be caused by several things.

Too much amperage will cause it...but you can also get undercut just by shaking too much.

click here to see the full web article of the overhead tee joint video shown above