6010 Root Downhill with 5/32"

watch more stick welding videos

If you searched for "tips for a 6010 root downhill using 5/32" rod"...

you found it.

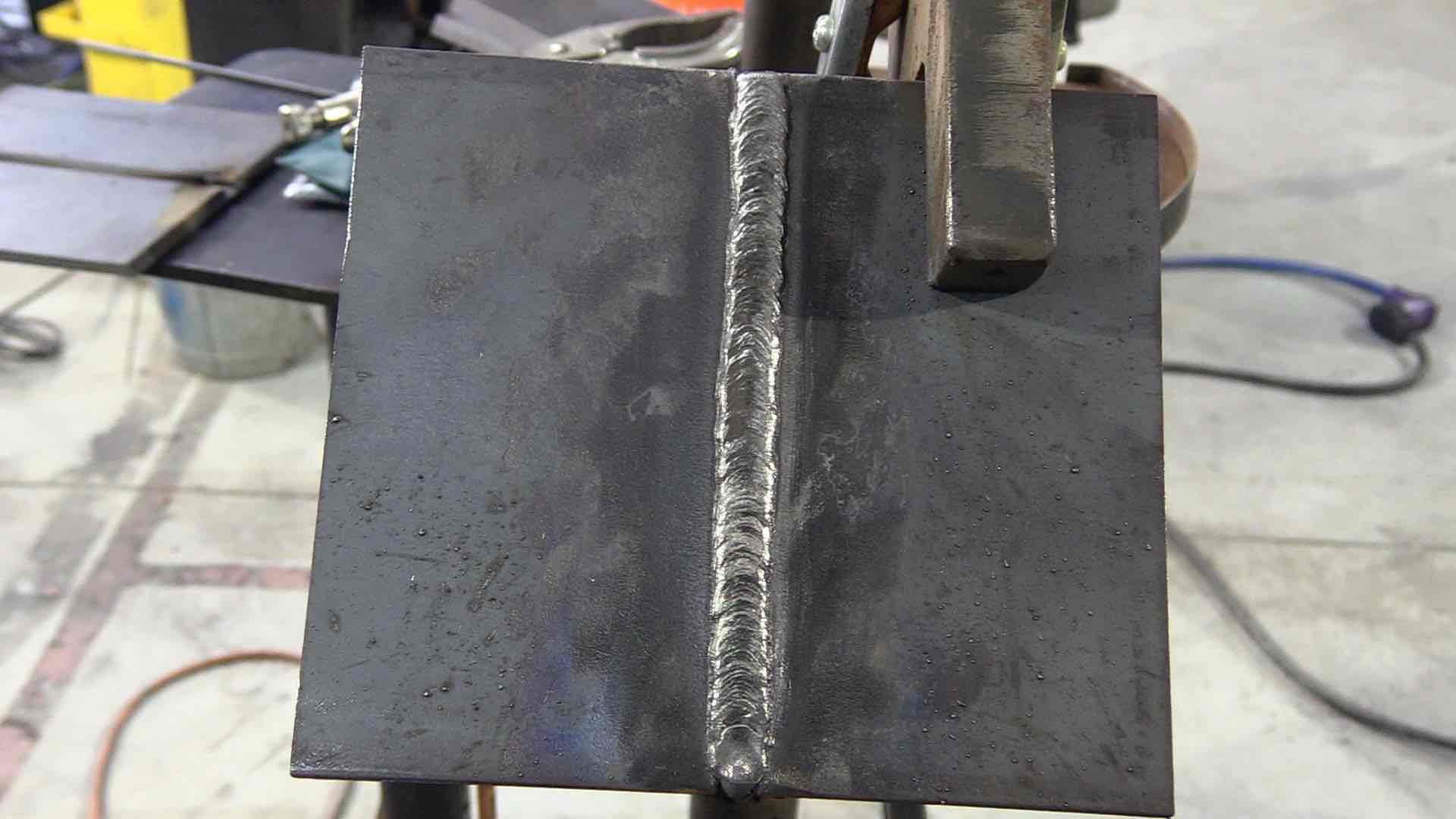

In this video we set up a practice plate at a 45 degree angle to mock up that 10 oclock area of a pipe joint.

Root pass was welded using 5/32" 6010

Fill and cover pass were welded using 3/16" 7010 electrodes.

Previously we filmed a vertical downhill practice plate welding the root pass with 1/8" 6010 and fill and cap with 5/32".

click here to watch the vertical downhill video using 6010 1/8"

6010 root with 5/32"

Why 5/32"?

first of all, this video is about using practice plates to build the skills need for passing a pipe welding test and also to weld downhill pipe in the field.

Downhill welding with 6010 and other XX10 electrodes is part of the procedures in API 1104 (American Petroleum Institute Standard for welding pipelines and other related facilities)

In the field a 5/32" rod welds farther with one electrode and also is just much more efficient for downhill pipe roots under the API 1104 code.

Amperage was set to 125-130 for the root pass.

Arc length, rod angle, and pressure make a lot of difference in a downhill 6010 root.

The fitup was as follows:

- 30 degree bevels

- 1/16" gap

- 1/16" land

With a 5/32" rod for the root pass, it is especially important to hold a tight arc due the the large diameter of the flux making it more difficult than a 1/8" to reach the root.

3/16" 7010 hot pass

Since this plate is a practice plate in preparation for a downhill pipe, this is a good place to start using the larger diameter electrodes that are used in the filed for downhill pipe welding.

After grinding the root ( this is part of the procedure we were following and is not normally required) The hot pas was welded using 3/16" 7010 at 145-150 amps.

3/16" 7010 fill and cap

Amperage stayed at 145-150 amps for the fill and cap passes. ( except was bumped up to 165 for a small stripper pass to even up the fill before capping.

This 45 degree position plate is one of the easier positions so using the larger diameter electrodes is not that difficult.

Where it gets harder is on the bottom of the pipe where gravity works against you.

Coming soon is an overhead practice plate and after that will come the 12" pipe joint using 5/32" 6010 for the root and 3/16" XX10 electrodes for the fill and cap.

The pipe welding video is in the works and will be linked up right here when it is done and ready for viewing.