6010 Downhill Root and practice

If you are practicing for the API 1104 6010 Downhill pipe welding test, I made this video just for you.

I think it is helpful to practice all the different positions using plate before trying pipe.

Why?

Because plate is cheaper, easier to prep, and a bit easier to weld if you practicing to weld pipe.

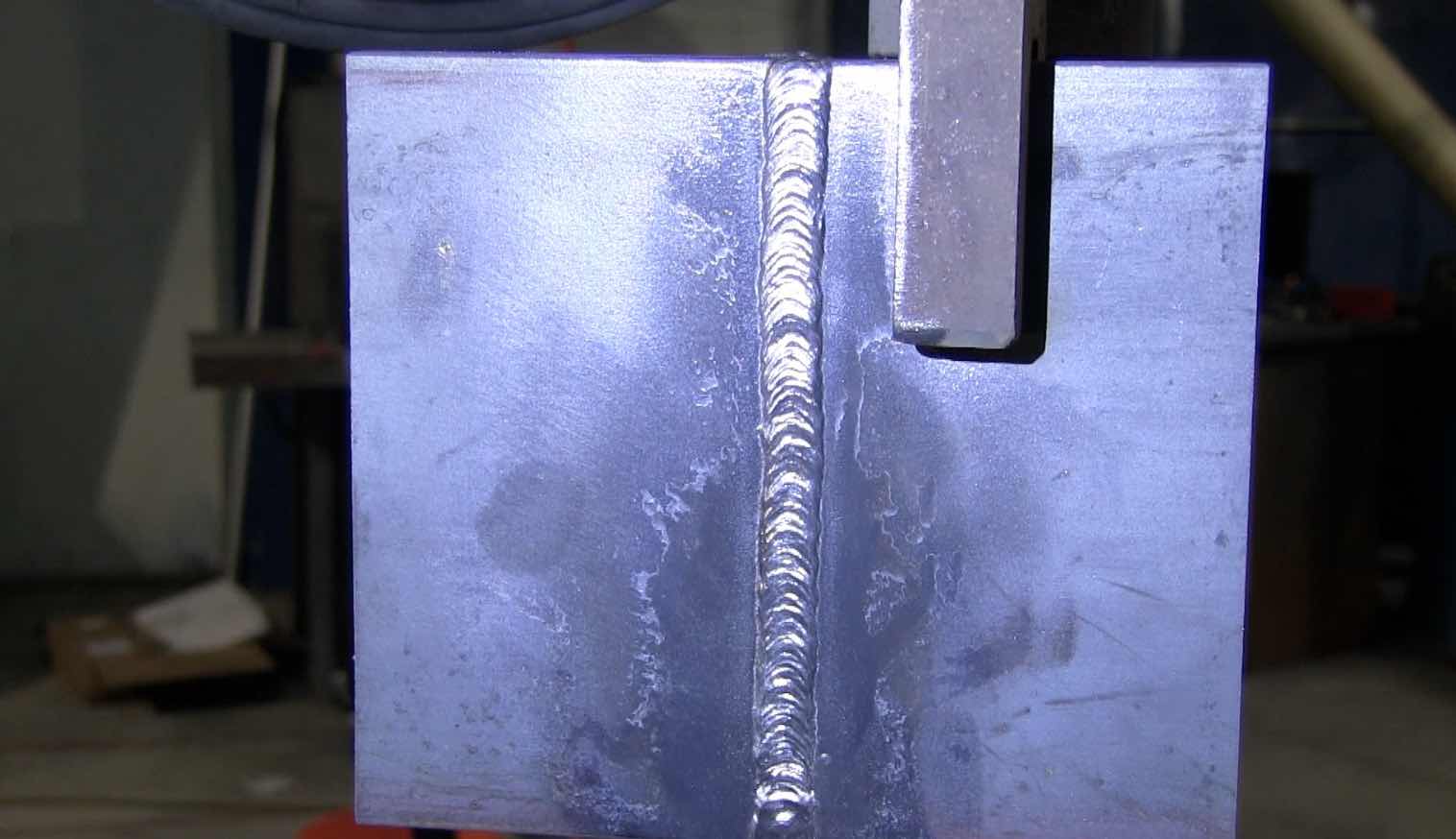

Fitup for 6010 downhill root practice

The plates are from Triangle engineering. they have a 30 degree bevel on them and are coated with a protective coating that can be welded over.

For this video we used a 1/16" gap and a 1/16" land.

It is important to get a good even fitup with no hi-lo (mismatch) and an even gap from end to end.

The tack welds will shrink the gap so make sure to gap the plates using a slightly larger spacer so that when the tack welds shrink, the gap will be 1/16". ( and if the gap is less, you can always open it up using a cutting wheel on a grinder).

Amperage for the 6010 downhill root

Amperage was set to 80 amps but was increased to 90 amps.

this will vary somewhat from machine to machine.

and also with fitup.

If your gap is more than 1/16" use less amps..and if your land is less than 1/16" , use slightly less amps.

and more amps if gap is tight but again...if gap is really tight, open in up with a grinder and thin wheel.

Hot pass with 5/32" 7010 hyp+

The hot pass was done using 7010 hyp + electrode.

the HYP stands for high yield pipe.

Amperage was set to around 135 for the hot pass.

In this video the root pass was ground out smooth, but that is not the norm.

Andrews company procedure calls for the root to be ground.

If root is not ground or barely ground, a slightly higher amperage might be called for.

Fill and cover passes

Amperage stayed the same from hot pass all the way out to cover pass.

This really depends a lot on interpass temperature.

On a test plate, heat saturates the plate rather quickly and so 135 amps seemed fine for the entire plate.

but on a larger piece, or a pipe joint, the piece would cool much more quickly and more amperage might be need after the hot pass.

Key things to remember

- fitup

- amperage

- rod angle

- pressure on rod

Fitup is really important.

Sure you can make adjustments to an extent but a really poor fit is hard to overcome.

Amperage will depend on several things like the machine, temperature of the metal, fitup, land, gap, and bevel angle. 90 amps should be close but as you saw in the video, we started out a 80 amps but it seemed cold and so we increased amps to 90

rod angle can be forgiving but also can be used to your advantage...it just takes practice to determine the best rod angle for a certain situation

pressure on rod depends on how close your amperage is in relation to fitup and other factors.