309 Tig rod for welding stainless to carbon and high strength steel

309 Tig Rod was designed to weld stainless steel to carbon steel and still have a strong ductile weld that can hold up to heating and cooling cycles.

304 stainless steel contains approximately 18 percent chromium, and 8 percent nickel...that is why it is also known as an 18-8 stainless.

Plain carbon steel does not contain any chromium or nickel except for maybe very tiny traces.

Why 309 tig rod? ...and not a nickel alloy filler metal

309 stainless steel contains a higher percentage of both chromium and nickel than 304 so that when 309 is used to joint carbon steel and stainless steel...and some carbon steel is mixed into the weld metal (called admixture or dilution) The resulting weld deposit still has favorable amounts of chromium and nickel to make the weld crack resistant and both strong and ductile.

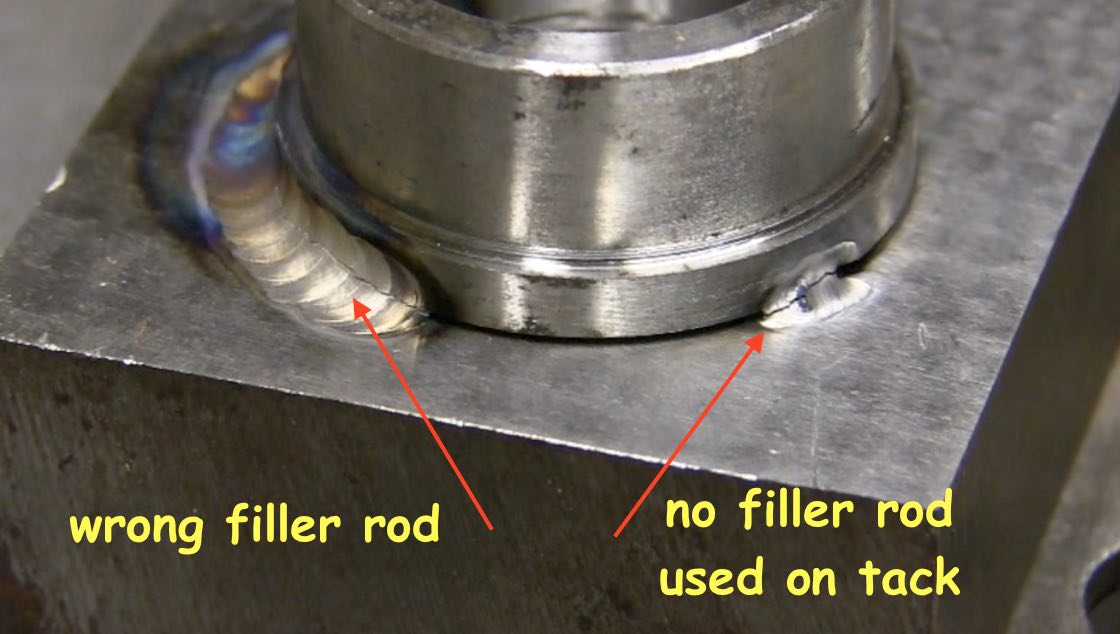

Just to demonstrate why you should select a rod that is backed by engineering data, I chose to use some Hastelloy filler metal that is not recommended for welding carbon steel.

Now one might think that a nickel alloy rod would be an ok choice for joining carbon steel to high strength steel...at least you might not expect that it would crack.

...and if I had chosen Hastelloy W, things would have turned out differently.

But I used hastelloy X.

But it's hastelloy right? and arent all the hastelloy rods pretty much the same?

Heck No!

This is a good example of the importance of following procedures.

one letter difference or one number difference can be huge when it comes to welding.

There is a big difference in Hastelloy W and Hastelloy X.

Here are the chemical compositions of both so you can see the differences...

Hastelloy W chemistry

- Ni- 63

- Cobalt - 2.5

- chromium - 5

- moly- 24

- iron- 6

- silicon- 1

- manganese- 1

- carbon- .12

hastelloy X chemistry

- Ni- 47

- Cobalt - 1.5

- chromium - 22

- moly- 9

- iron- 18

- silicon- 1

- manganese- 1

- carbon- .10

- W- .6

Hastelloy W is much higher in nickel and moly, ...and lower in chromium.

and Hastelloy X even contains about .6% W (tungsten)

I said all that to say...

Its best to choose a rod that has some engineering data to substantiate a likelihood of success.

There is plenty of data out there on using 309 for welding stainless steel to carbon...