Uphill Welding with 7018

When you are welding uphill with 7018…or any other rod for that

matter, you typically will use less amperage than you would for flat or

horizontal welds.

So how hot is hot enough? and how hot is too hot?

that's exactly what I am working on today.

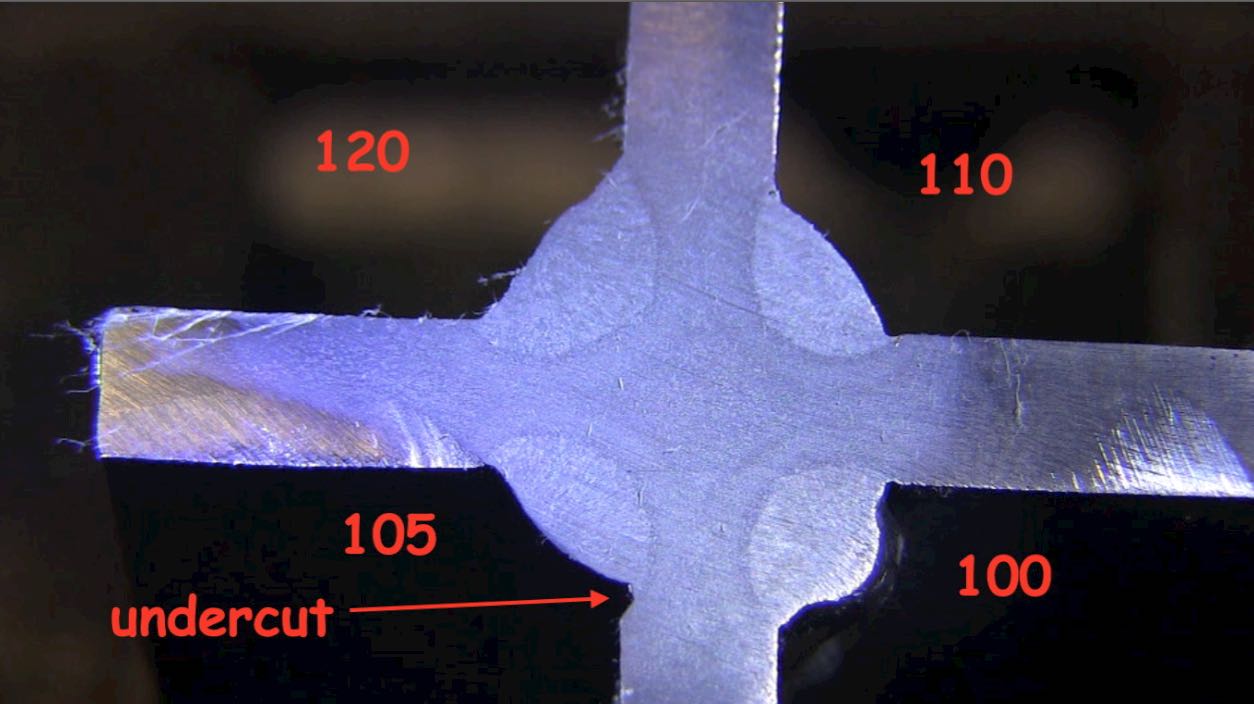

I set up a double sided Tee joint for this video so that I could weld 4

joints at 4 different amperage settings to determine the sweet spot

amperage setting for uphill 7018 1/8” (3.2mm) electrodes on 1/4” (6mm)

thick steel.

So here is what I did…

First joint was done

at 100 amps. Then I cooled the metal all the way before increasing

amperage to 110 amps…then I cooled it off again and increased amps to

120.

At 120 amps, I could tell, things were going to get out of

control if I went any hotter, so I cooled the piece and welded the last

joint at 105 amps.

Clams for Uphill Welding with 7018

In Stick Welding, there is something called the Clams Acronym that helps to remember the essential things that go into a good weld.

- Current

- Length of Arc

- Angle of electrode

- Manipulation of electrode

- Speed of travel

With CLAMS in mind, Here are some observations from this video on vertical uphill welding with 7018 electrodes.

Current

100 amps is about as low as I want to weld with a 1/8” (3.2mm) 7018.

and 120 was pretty close to max amperage for vertical uphill on 1/4” thick steel (6mm) thick

115 amps probably would have been optimum for the machine I was using

Length of Arc

I tried to maintain a very tight arc length. Not forcing it into the puddle, but very tight.

good advice for stick welding is to set the machine hot enough that the rod wont stick when you hold a tight arc…..then hold a tight arc.

this advice works for all positions but for vertical uphill, less amperage is needed than for horizontal or flat.

Angle

I tried to maintain a 90 degree rod angle knowing that I would probably get into a slight push angle…just seems to happen with the helmet drops

Manipulation of the rod

slight manipulation helps me see where I am going but allowing the light to change. A slight manipulation of the electrode can also help to flatten out the face of the weld

Speed of travel

A general rule of thumb in stick welding is to travel slow enough not to leave undercut….and not much slower than that.

Also, when you are using a slight manipulation technique, its important to pause at the edges of the weld to let them fill with weld.

There is another issue not addressed by CLAMS and that is Arc Blow.

Arc blow can be a real problem on small pieces like I was welding in the video.

Generally speaking, welding at the lower range of an electrode helps prevent arc blow and in this video, For example, I didn’t notice much arc blow at the 100 and 110 amp settings using 1/8" 7018. But at 120, I definitely noticed arc blow toward the top of the weld.

Arc blow happens due to magnetic forces setting up in the work piece that affect the way metal droplets deposit across the arc….

So positioning the ground clamp directly to the piece and midway seemed to help.