Mig Welding Tips

See what our Forum members are saying on MIG Welding Tips

these stronghand mig pliers have a chain so that you can hang them on your welding table.

grab a pair at weldmonger.com

Uphill with Miller Mulitmatic 220

Weldmonger Hybrid Gloves are for both TIG and MIG

A good ground, A short stickout, The right mig welder settings, and a good technique and you are on your way to making better welds. Stick around and sign up for the Mig MythBuster series

"Welding School can be a really good investment..if you learn to weld pipe and are willing to travel ... "

Mig Welding Square Tubing

Hey Welder! have you seen the Series on Mig Welding Basics that includes setting the mig machine along with welding vertical and overhead?

just click here to check it out

"I may not be the best mig welder in the world, but that doesn't make it right?!.. "

- mig welding is probably the easiest way to get started welding

- bare wire mig with .023" wire is best for auto body work...

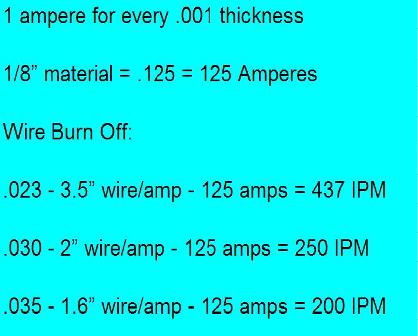

Mig Wire feed settings Chart

Ok, So what does this chart mean?

Its just one way to get some voltage and wire feed settings if you dont have any idea where to start.

lets take 1/8" carbon steel for example

1/8" inch = .125

one amp per .001" = 125 amps

if you are using .035" wire, the chart uses a factor of 1.6 to figure the wire speed for .125 metal.

125 x 1.6 = 200 inches per minute.

that gives you a good starting point for short circuit mig welding.

now just adjust voltage to get a good smooth bacon frying sound.

(assuming you are using short circuit mig with 75/25 gas )

Want to know the 7 Biggest fattest mig

welding myths?

Just fill out the form below and get them in your email.

I hate spam and will not spam you

And the Top 3 MIG welding tips are...

#1 MIG welding tip...Get a better Ground clamp.

This is probably one of the most important mig welding tips ever!

Ever heard someone light up with a mig gun and it sounds like a drive-by shooting?

You know what’s wrong? Bad ground!

That’s right a bad ground.

It is such a simple fix but I hear that sound all the time.

People have trashed machines and bought new ones for this reason alone and all the while, all that was wrong was a bad ground. Why? Have you paid close attention to ground clamps recently? They suck! I mean they really suck! It used to be that ground clamps were made from copper. Now they are plated steel with a tiny piece of copper on the jaws.

Guess what? The old ones are better.

You could say that about a lot of things right? But here’s a secret: you can still buy the old ones. It is no secret that copper is the best conductor. That’s why copper ground clamps are better. Especially ones that have a strong ass spring.

Bottom line is...in order to get good starts, you need a really good ground. I have a secret weapon that I use to get a good ground. And it involves copper..

Mig Welding Tip ...A Better Ground...

#2 Mig welding tip... Watch Your Stickout.

The second most important of Mig welding tips is "stickout"

Stickout is misunderstood. What it really means is the distance from the mig welding tip (also called contact tip) to the arc.

Not the distance from the nozzle to the arc!

Too long a stickout will soften the arc and make the weld pile up.

A longer stickout works ok and can be a good thing on really thin sheet metal like body panels.

and for high amperage spray transfer a longer stickout is preffered.

But if you want a good crisp arc using short circuit mig on thicker metal, keep the stickout less than 1/2 inch.

tip recessed= too much stickout=gorilla welds

Thats better...tip poking out= shorter stickout = better penetration and smoother welding on thicker metals.

some welding companies offer different nozzle /contact tip combinations for different types of mig welding but other times, you might need to trim the nozzle.

#3 MIG Welding Tip..Learn to weld Uphill

Another of many important MIG welding tips is to Weld Uphill on anything thicker than 1/4". Just look at the lack of fusion in the photo below.

this was a good looking weld but it hardly has any penetration at all.

That opening on the bottom bead was a real eye opener for the student who welded it.

The weld above is a lap joint welded first and a tee joint done on top of the lap to conserve metal.

After stacking lots of beads on the tee, the stress pulled the lap joint weld loose.

That bead just didnt penetrate.

#4 Mig Welding Tip...get a good Auto darkening Helmet

I Know there were only supposed 3 Mig welding tips...But this one is probably as important as any...

Even moving a quarter inch off track when you nod your helmet down can

really screw things up with mig welding. Why? Because Your mig welder does not care about you.

Mig machines just start laying down metal without concern for your well being

or whether or not you are on track. With an Auto Darkening helmet you

can see where your wire is pointing before you pull the trigger.

More Mig Welding Tips and Articles

Let’s talk about flux-cored and solid wire differences and 115v wire feed welders.

Nearly all wire-feed welders can use flux-cored wires.

Whether 115v or big heavier duty units like the Millermatic 250.

For right now I am strictly talking about self shielded flux core wires.

With self shielded flux core, the flux is inside the wire and creates a shielding gas and slag when the wire is consumed during the welding process.

No compressed shielding gas is needed. This wire runs similar to a 6013 Stick electrode.

...has considerable spatter and slag on the weld that must be removed. But the good thing is the weld area needs minimal preparation.

Self shielded Flux-cored wire works well in windy conditions.

The small diameter stuff you see in big box stores like Home Depot, Lowes, Tractor supply, etc....is most commonly used for hobby projects and farm work.

But if you are interested in welding heavy sections of steel with mig outdoors, you should definitely check out Hobart Fabshield 21b.

It runs pretty freaking awesome. It runs almost like a 7018 and with no shielding gas. It passed the bend tests that I ran with no problem and I really liked being able to take the nozzle off and weld.

The tests I ran were vertical uphill and overhead. I don’t think downhill would be worth a crap. But like I said, it’s kind of like a 7018 and 7018's don't like going downhill either.

Solid Mig wires require a shielding gas that comes in a cylinder and

is usually either straight CO2 or a mixed gas of 75% Argon and 25% CO2 for mild

steel.( for other mig processes like hot spray transer, other Argon mixed blends are used)

The advantages of bare wire aka "hard wire" with shielding gas are a clean weld with no slag and minimal spatter and the ability to weld thinner (24-gauge) materials.

The weld area needs to be clean within reason.

Solid wires are commonly used for all kinds of fabrication and repair as well as for auto body work and in other applications where thin materials are welded.

A good ground, A short stickout, The right mig welder settings, and a

good technique and you are on your way to making better welds.

Search here for more Mig welding tips?

The best way to find information on this website is to use this search bar