TIG Welding (GTAW) - MIG Welding (GMAW) - Stick Welding (SMAW) Questions, and Answers

click here to go to the weldingtipsandtricks forum

Tig Welding Tips

Mig Welding Tips

Stick Welding Tips Stick, Mig, Tig Welding Questions, and Answers

Question:... I just acquired a lincoln AC 225 amp arc welder a few days ago. I have been playing around with some scrap metal and some 6011 rods, but really have no idea what i am doing. I have read some of your tips and tricks but i can't seem to get a nice weld, or at least one that looks good. I really have no idea of good practice or techniques. Would you be able to help me out at all?

Answer At your level, just striking an arc without sticking , and then running a straight bead is the first thing to learn.

I will tell you that the number one thing that virtually everyone does wrong when they first stick weld is to hold too long an arc. That’s because the rod is always getting shorter as it burns.

Make sure the machine is hot enough so that when you hold a very tight arc…the rod wont stick..like a close enough arc that you can feel the tip of the rod dragging the metal.

Then just move the puddle along slow and steady. You can experiment with making little circles by tracing the puddle but don’t get carried away… Once you get beads down pat, Some of the best practice you can do is to stack beads. They call it padding beads in school. Just get a flat piece of steel about a quarter inch thick, and run a straight bead near the edge. Follow it up by stacking another bead halfway over that one. Do it again and again until you get straight even beads with little or no valleys in between. Good luck,

Question: how can I get better ground with the standard ground clamp for mig welding? If that isn't a good option how do I change my ground setup? If my machine doesn't show volts how can I tell the voltage? Thanks

I created a separate web page to show you how to get a better ground when MiG welding. of course this will work for tig and stick welding too. It's just not as important for tig welding and stick welding because you dont have wire constantly feeding.

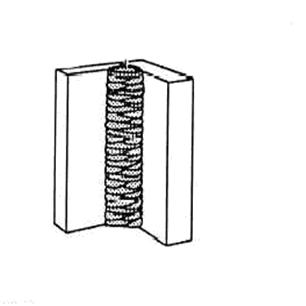

Here is the text explanation: To make a better MiG welding ground clamp,that works for tig welding and stick welding too. (just more important for mig welding) Find an old welding lead or ground cable and cut off about two feet of cable. Then Strip off the insulation and tape the ends. Fold it in half and put the ends in a vise. Stick a screwdriver in the loop and twist it pretty tight.

Now you have a cool tool that gives you a constant ground. Why??? Because its copper, and because when you clamp this thing to what you are welding using your old ground clamp, you have literally hundreds of little contact points that will never lose the ground...not even for a second. This is critical when MiG welding because your MiG machine does not know or care if you lose the ground for a second. It just keeps feeding wire. That is the number one cause for poor starts.Try it! This makes a much better MiG ground clamp than what comes on most machines.

the other option is just buy a copper alloy ground clamp but it still wont work quite as well as this trick See how to make a trick ground for mig welding

NEW!!

7 Days of Down and Dirty Tig Welding tips like...

Tig Torches - the right one to buy , Tungsten Electrodes - just keeping it simple, Tig Welding Rods for most any job , Remote amperage control - Foot or hand? , Argon and Helium...the answer is. , Welding gas cylinders - Big? Small? should I rent or buy?, Shielding the Back side of stainless.

If your machine doesn't show volts, here is one idea: If you have access to another machine that you know the settings for or If there is another machine nearby that you know settings that work well, and if both machines are set up with the same size and type wire and gas, then just pull the trigger and count 6 seconds....thousand one, thousand two...etc. Then measure the wire that just came out to the nearest inch and add a zero. For example, 25 inches = 250 inches per minute. Now that you know that you can get a piece of scrap and adjust the voltage till you get the bacon frying sound (if you are welding short circuit mig).

Heres a short Youtube video that demonstrates setting wire feed speed the same from one machine to another.

Question I have to go in a couple of weeks and run a plate test with MIG welding uphill. I've never run MIG welding uphill and am wondering what technique to use and also what size gap to use. I've welded plenty in the past with MIG welding downhill but not up. This will also be a visual inspection as well as x-ray. Thanks.

answer...... there are a lot of variables that are not mentioned here. like metal thickness, base metal type, filler metal, bare wire or flux core? Just for a start, I am going to assume that it is GMAW-s short circuit mig with e70s6 bare wire and 75/25 argon/c02 shielding gas. Some plate tests for mig use a downhill root pass with uphill fill passes. If thats the case a 1/8 " gap usuall works well if the degree of the bevel is 30-37.5 degrees. If the bevel is 37.5 deg , put a 1/16 land on the bevel first. If the root is uphill, again its going to depend on the bevel, but the gap will always be less than for downhill welding. I would recommend 3/32 with a 1/16 land. Less than that and you risk the gap closing up on you too much. you can always adjust the voltage and wire speed and you can even adjust your technique to compesate if it looks like your going to keyhole too much. A good starting point if the test is a 30 degree bevel uphill all the way is: Root pass...17 volts and around 200 inches per minute on the wire feed. filler and cover pass....19 volts and around 240 inches per minute

thnks for your question.

Question I have never welded before in my life and I know no one that can show me welding tips and tricks and how to weld. I am ready to visit the library and read how to weld. Before I do that, I would like to focus on a specific type of welding. I know there are ARC Welders, MIG Welders, etc. What is the difference? Which is best for certain jobs? I know there are different types of welds too (IE Spot welds, etc). That's it. That's all know. I am a good mechanic and i do alot of car engine work and want to start doing some body work which will require spot-welds and welding in some patch panels. Can you point me in the right direction? Any advise would be appreciated. Thank you!

answer.....

you could probably get the job done with tig welding or even with stick welding if you got some 1/16 rods..But for body work, you definitely need a 115 v mig machine with gas shielding ability. dont buy one of those cheap ass machines that only use flux core. My advise is to shop ebay, craigslist or your local pawn shop and get a Lincoln Electric Weld-Pac 100 that comes with a gas solenoid and a regulator for 75/25 argon/co2. You can always swap to flux core for outside jobs (like welding your brother-in-laws wrought iron mailbox back together after his ex-wife backed over it.) But if you get a cheap one it might not even be able to convert to the gas setup.

Another really good 115v mig welder is the Hobart Mig Welder Handler 140

Your question;

Thanks for the quick response last time! Here's another!

I get a ton of broken cast iron exhaust manifolds in here. I typically bead blast the area, "V" out the crack, then wash it down with carb cleaner. I then pop it my wife's gas grill and heat it to about 700 degrees, then burn myself carrying it to the welding bench, then proceed to weld it. Oh, forgot the best part, I don't have any TIG nickel rod so I buy stick rod and beat the flux off it, then TIG it together..... Sometimes it works, sometimes it doesn't. Actually most times it works, but please advise me what rod to order and am I wasting time with the gas grill? Thanks again!

Answer:….. On any cast iron engine part, If it works most of the time, you are doing as well as anyone, better than most.. I have done the gas grill preheat thing myself. I do not think you are wasting your time with the preheat...keep doing the preheat. If you buy some Cronatron 211t nickel tig rods, you will at least save some time not having to beat the flux off the stick rods. (something else I have done). Something I have been meaning to try is to get a cheap grill and only use it for heating cast iron parts. I was thinking of permanently attaching a ground to the grate and welding the part right on the grill so I can let it cool slowly. (disclaimer here, I am not saying this would be safe, results may vary, spilling hot coffee in your lap hurts, etc.) It is depressing when you can hear it crack before you are even done. I have had some success with peening the weld every inch or so with either a ball peen hammer or chipping hammer. It retards the shrinkage stress a bit.

Fyi.. Carbon steel will harden if it has about 0.3% carbon... Cast iron has more than 10 times that much carbon! hardening in the weld area is unavoidable unless you can weld it red hot and cool really slowly.

Your Question: Welding liabilities - As a small business outfit ,What can I legally weld on without getting sued or be held accounted for weld failure? Do's and don'ts Like welding across a stress member, auto,marine etc. Thanks

Answer…… This is a bit outside the scope of questions for weldingtipsandtricks.com but I will be happy to "weigh in" with an opinion anyway. With our lawsuit happy culture I am not sure there is anything you could weld that would be completely free from the risk of litigation. I have researched this topic quite a bit and one phrase seems to reoccur time and time again : "Due diligence" Due diligence could be defined as the opposite of "Negligence" Due diligence in certification of welders,,,in qualifying procedures or using prequalified welding procedures,,,in following best practices,,,,, etc.

It wont free you from litigation but if a weld fails and there was "due diligence" in all the important areas, it would be a lot harder for an attorney to prove negligence. That said, I am not a lawyer. I dont even play one on TV. So any advice I give concerning the law is worth exactly what it costs you. I have an aversion to making decisions based on fear of litigation but it affects by decisions anyway. Even answering this question could put me at risk... Unfortunately, thats the world we live in. I understand where you are coming from. Small businesses like yours work hard and compete with illegal labor issues and unfair global competition only to be at risk for being wiped out by a lawsuit.

Here is a short and simple description of a due diligence welding program: If the work you are doing is governed by a welding specification, get a copy and learn it. and comply with it. If you are not required to comply with a specific code, and you want to have some type of standard for qualifying welders, use AWS. B2.1 Qualify the welder and procedure . you can do this at the same time. only qualify to the task. overkill costs too much. for example, If you only do fillet welds , no need to use a full penetration groove weld for qualification. write a very basic welding quality manual that states how you qualify welders and how you follow established welding procedures or the code you are working to then do what you wrote. or comply with the applicable code.

feel free to ask more questions either by submitting at www.weldingtipsandtricks.com or by using this email

-----------------------

your question was: I've just bid a job that specifies 304 SS for a tank. Am I better off using 304 rod or 316? My knee-jerk reaction tells me 304 but a local (retired) aviation welder tells me either will work but he has had better success with 316, even on lesser grades of stainless. He recommends the 316 because it is 'purer', your thoughts?

My answer is: I cant think of any stainless easier to weld than 304. The commonly used tig rod for this is 308 or 308L ( L is for low carbon). I wouldn't waste money on 316 rod . It might flow a little better but any real benefit is mostly just personal preference. I have gotten myself into trouble before by trying to use one grade higher on welding rods. I am an aviation welder myself and one of the most commonly specified rods for welding stainless steels and disimilar metal welds is hastelloy W. But I have seen instances where hastelloy W was used to repair a cleaning solution tank made from 304 ss and the weld degraded prematurely due to the acidic solution in the tank. Even though the hastelloy W was a higher grade alloy it wasn't as good a choice as simply using good ole 308L. 316 is not any "purer" it just has a little more nickel and about 3% molybdenum added. Its more corrosion resistant but also more expensive and if 304 has been specified for base metal, then the corresponding 308L filler metal will be the safe choice and will work just fine.

thanks for taking the time to submit a question and feel free to email anytime

Jody

Your Question,,,i have a 140hd lincoln electric welder. I am trying to weld a quarter panel of a nissan altima. What do you think will be the best setting and wire to use on it? thank you

Answer:…. On thin sheet metal like you are asking about, .023-.025" e70s6 bare wire with 75/25 argon/co2 is the best. The wire feed speed will probably be not much over 100 imp (inches per minute). All you have to do to figure out wire feed speed is press the trigger and count ...thousand one...thousand two...thousand three..... count to six , and measure the wire that came out. Round to the nearest whole inch and add a zero. That is your ipm. for example, 12 inches = 120 ipm. Voltage should be set to match using a piece of scrap as close as possible to the thickness of your actual job. Just adjust the voltage to get a nice bacon frying sound. Another big big factor will be a good ground. Just clamping a crappy ground clamp just anywhere will give you crappy starts. Make sure to sand an area somewhere to clean bright metal free from paint or undercoat. If you cant find a good place to ground, use the technique on this link and tape the copper braided wire to a bare metal place. https://www.weldingtipsandtricks.com/mig-welding-ground.html The ground is really important. All vertical welds should be downhill. and You should only weld about 1/2" at a time skipping around in order to avoid distortion.

If all you have is flux core wire, you just need to get some scrap sheet metal or a fender from a junk yard to set the machine.

Good luck. and feel free to email this address with more questions.

jody

Your question is hello i started welding pipe 6 months ago, i started just rolling them out and starting from the middle up. As of today i tried my first position weld, i had a hard time to get cap to build up. Instead i had undercuts along the sides. i have tried the 6g position and found it easier to weld then the vertical position.i run my root 3/32 gap with 1/8 landing with 1/8 6010 rod at 110amps, my hot pass is with 3/32 7018 h4r at 100amps and my cap is the same rod the only difference is that i try run a stringer on my hot pass and weave my cap to tie in the sides. my root went in pretty good my hot pass seemed kind of shallow so i added a filler pass. when i started my cap the rod seemed to gouged my weld and stopped immediately, and tried again with more angle it suck and thought it was going good until i removed the slag it looked like crap with undercuts along both sides and was really shallow i dont know whats going on but i am going to keep practicing oh the pipe i was welding was 4inch schedule40. any advise will help i am a young welder willing to learn and listen

Answer..I was reading the miller website the other day and this comes to mind...In stick welding remember the word CLAMS: Current setting, Length of arc, Angle of electrode, Manipulation of the electrode and Speed of travel. If you're just learning the Stick process, technically called Shielded Metal Arc Welding, remembering these five points will improve your welding technique.

now this might sound goofy but it gives me a good launching pad to talk about what might be going wrong with your pipe welds. first of all everything sounds really hot. Your root pass, if you are welding uphill, would need to be around 90 amps. Since the wall thickness is only around 1/4" on 4 " sched 40 pipe, I would run the root, then a hot pass also with the 6010. and then only one pass with 3/32" 7018. I like to be about 1/16" below flush when I weld the cover pass. I am guessing your 3/32" 7018 is glowing red when you burn down the rod to where it is about 4" long. If that is right, you are just too Damn hot. The rod runs totally different when it gets that hot and you start to have arc blow and its hard to control the arc. There is not much wall thickness to take the heat either so the heat build up and causes extra problems. Welding on red hot metal is like adding an extra 30 amps. Also I would wait a few minutes between passes. Once you get the current set right, For me, arc length and rod angle are the two biggies on pipe welding. Coming off the bottom at 6 oclock keep the rod dead nuts straight in. If the current is set right, you should be able to hold a tight enough arc to actually feel the rod rubbing the metal without the rod sticking. for a 3/32" 7018 that should be about 85-90 amps. I will be throwing up a YouTube video explaining how to maintain rod angle welding pipe pretty soon. And it will be on the Stick welding page on www.weldingtipsandtricks.com I hope some of this helps. There is no feeling better than having a skill

thanks , jody

feel free to email anytime

Lennard, you submitted the question:

Hey i am Lennard I am from the netherlands i am an 16 year old student with some mig welding skills i have mig weldings skills for around 1 and a half year experience and i need to weld up hill i for my certification its on friday the 22th the examinator comes and i wanne graduate so couldt u help me i need to weld uphill i got an Cebora welding machine i dunno excatly what type cause i am at home now but if i go welding uphill my voltage is 18 and my amps are at seperating from 89 till 98 so i dont know if thats good but i couldt use so some help with this one Welding Above my head its really hard thanks to check this e-mail and if u couldt help me i wouldt really appreciate it ......

Answer, ….. I would be happy to help you Lennard. But first I really need to know a few more things:

• Is this carbon steel? and what thickness?

• are the joints you will be tested on open butt v groove welds or fillet welds?

• what gas mixture are you using?

• filler metal? e70s6?E70s3?...flux core? bare wire? what size wire?

I will give you some advice as soon as I get this information

jody www.weldingtipsandtricks.com

sorry i didnt told u yet the thickness is 1 centimeters also like 10 milimeters lenght 250 milimeters wide 50 milimeters its normal steel welding with co2 and argon gas on the v grove they have to be filled but not above the mothermaterial and can u tell me how i can weld above my head when i do that i tune the machine on 143 amps 21 volts i use the same material for it ill take some pics to morrow what i need to weld to

answer.... The best advice I can give you for welding overhead with Mig is pay attention to 3 things: 1. Make sure and have the machine set hot enough...I use the same settings I would use welding flat. 21 volts sounds pretty good but is probably too hot for an open butt root. 2. Make sure your stickout it right...Stickout being the distance between the arc and the copper contact tip. Make sure the contact tip is at least flush with the nozzle and preferably protruding about 1/16". Even if you have to trim the nozzle to get this it is well worth it..... and keep the stickout to 1/2"--3/8"...this is really important. 3. keep the torch angle to a minimum. Dead nuts straight in is good . if you are welding an open butt v groove weld, use about a 5 degree drag angle for the root...and a 5 degree push angle for the fill passes.Stay on the front of the puddle all the while keeping your stickout no more than 3/8" The Two problems I see most often on overhead mig is too much stickout and too much torch angle..number three is not hot enough. Using a long stickout along with not enough amperage just makes the weld pile up high. Using enough amperage, good stickout, and correct angle lets the arc force punch the weld and helps it flatten out.

If you have more questions , I will answer your emails. Dont be afraid to ask...GOOD LUCK www.weldingtipsandtricks.com

your question is: what is the thumb rule for the ampere range in different welding processes?

answer....There are many "rules of thumb" this is probably oversimplifying but..... for Tig welding, one amp per one thousandths of thickness up to .250" and for single pass welds.

For Stick (SMAW) its really more by the diameter of the electrode, 25-35 amps per 1/32" of electrode diameter IE. 1/8" rod =100-140 amps

For Mig (GMAW) short circuit, too many variables to have one rule of thumb but here is a link to an excellent guide.

http://www.airgas.com/documents/pdf/MIGWire.pdf

thanks for your question

jody www.weldingtipsandtricks.com

Your Question is for the welder qualification as per asme sec 9, qualification in plate qualifies in pipe or not?qualification in pipe qualifies in plate or not?

Answer, I dont have access to a copy of ASME section IX, but found this link that has the information you want. basically pipe qualifies for plate (with position and thickness limitations) but not plate for pipe (except for equal to or larger than 24 inch diameter pipe) but there are positional and thickness limitations to consider here also. here is the link. http://www.weldinginspectionsvcs.com/qw461p9.htm

thanks for sending a question

Jody

www.weldingtipsandtricks.com

Your question is... I have a Millermatic 180 and have been using a argon/CO2 mix. There appears to be a leak in the system and if I happen to forget to shut the tank off when done for the day, I often find my tank empty. I am thinking of trying out the flux core wire. Are there any pros/cons to using this?

I would try to find the leak with a spray bottle of soapy water... Even though I really like Miller machines, My Dynasty 200dx has some pretty chincy hose clamps on the inside of the machine. Make sure the machine is unplugged first, and pressurize the system. Then take the cover off and check at each hose clamp with a little soap solution.

I would definitely get a roll of flux core just to have on hand. I really like the Hobart Fabshield 21b . If you are currently running .035 wire, You can get fabshield 21B in .035 diameter also so you don't need new drive rollers or a new liner.

There are 4 main drawbacks....1. more smoke, 2. some slag on the weld that needs to be cleaned off, 3. you will need to change the polarity to DCEN. (this is pretty easy) 4. really thin sheet metal will be really hard..but you will have your gas on hand or those situations anyway

The pros are: you can weld outside in the wind, you don't need any gas, you can take the nozzle off the gun and really see what you are doing. and you will get better penetration.

All in all , getting some flux core will make your machine more versatile.

thanks for submitting your question.

Jody www.weldingtipsandtricks.com

Question I want to be a pipe welder and i am gonna go to a school and get a certificate. How should i go about breaking out being a pipeline welder.

answer...... If at all possible, Go to either Hobart welding school ( HIWT Hobart institute of welding technology) or Tulsa welding school ( they now have a campus in Jacksonville FL). Hobart has excellent job placement services and if you decide to get into a pipefitter apprenticeship program, you will get a good bit of credit for time served at Hobart. Local Tech schools used to have pipe welding programs but many of them have been watered down and dont have instructors qualified to teach pipe welding. I would also recommend learning tig welding mig welding as well as stick welding. You will be more valuable and hirable. Wouldnt it be great to be able to tig weld,stick weld, and mig weld and be able to pass a tig welding test, mig welding test, or stick welding test, no matter what was thrown at you?

Question what is a 6g position , What is the g6 welding test , what is the difference ? Thank you

Answer.... 6g position means that a pipe that is positioned at a 45 degree angle. A g6 welding test is probable just someone getting "6g" backwards. 6g test means a Pipe test on a pipe that is positioned at a 45 degree angle. It is also called an "Arkansas bellhole" test. The reason for the test is that it is considered the most difficult position to weld because it involves welding in all positions and because it tests your right handed and left handed versatility. Virtually all welding codes recognize this position as more difficult and use it for an all position qualifier. Another reason it is used for certification is because it really simplifies things. Instead of welding 3 or 4 different tests to certify in horizontal, vertical, and overhead positions, The 6g welding test gets it done with one test.

Question Can Chrome Moly Steel be welded with Shelf-Shielding Flux Core Wire and still be strong?

Answer..... Yes it can... but it depends on the thickness being welded and a lot of other things. If it is thin wall tubing, under .100" the cooling rate might be slow enough for the weld and heat affected zone to be ductile enough. Flux core is probably not the best choice, but it could probably be done. There is quite a bit of tig welding information for welding chromoly tubing without a preaheat or post heat treatment as long as the wall thickness is around .100 or less. If it is thicker, probably not. at least not without a good preheat.A lot of times when the subject of welding chromoly comes up, it is for home built or experimental aircraft. That is pretty scary. For any aircraft application, get a professional welder to tig weld it for you and don’t use flux core. For heavens sake, it’s your ass way up there.

Question I was just wondering what type of a weld is stronger Mig welding or Oxyfuel (gas welding)

Answer....... If done right, mig, tig, and stick welds will be pretty close in strength. The area around the weld will probably be much stronger on the mig weld. Oxyfuel welding heats up a large area and for cold rolled steel parts that means a large area that got softer and weaker. Mig welding done right has a pretty small heat affected zone. So does tig welding.

Question........ My question since I am new to tig welding and Tig aluminum welding, is can I use carbon dioxide as an inert gas.???? or do I need Argon only....how about argon/c02 mix?

Answer....... Use only pure argon for tig welding or you will cuss....a lot!!. When you get some seat time and get really proficient you may find a mix of 50/50 argon/helium to be useful. I know I use it all the time and it really makes a big difference when tig welding thicker aluminum.

Question.....HELLO, IM LEARNING HOW TO WELD, MY TEACHER SAYS THAT IN VERTICAL WELDING I SHOULD ALWAYS WELD FORM BOTTOM TO TOP, BUT I WAS WATCHING A INSTRUCTIONAL VIDEO AND IT SAYS THAT IT CAN BE DONE FORM TOP TO BOTTOM WICH FOR ME IS MOR EASY, PLEASE ADVICE.

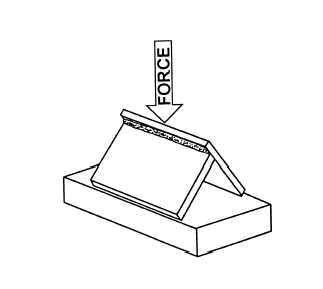

Answer..... if your instructor is telling you to weld uphill, I am going to assume that we are talking about short circuit mig welding. Short circuit MIG Welding downhill on anything ¼” and thicker just will not penetrate consistently. For sheet metal thicknesses like automotive body panels, downhill is better, but for thicker metals, uphill welding is necessary. If you want proof, set the mig welding machine to 18 volts with 200 inches per minute of wire feed speed. Weld a ¼” tee joint downhill on one side. Don’t change the machine settings and then weld another ¼” tee joint uphill. Now try to break the weld by either putting the welds in a vise or on a heavy table and applying force. (I will post this answer on www.weldingtipsandtricks.com with an image of how to test the weld)

Vertical Uphill Mig weld

99 times out of 100 the downhill will break easily with evidence of lack of fusion in the root of the tee joint. The vertical uphill joint will be much harder to break and sometimes will not even break. It is that much stronger even if it is uglier. The trick is to learn a technique to make the uphill look good not ugly.

Welding Questions and FAQS. (what are FAQS?)

Question: Why downhill welding is preffered for pipeline welding? apart from the high production rate what are the technical reasons if any?

There really are no technical reasons for the downhill welding aside from the fact that so much of pipeline welding is done outdoors that stick welding has been favored for years. Root passes are usually done downhill with 6010 rods and then it takes a 6010 hot downhill pass to burn the slag out of the root pass. After that I think its strictly a "getterdone" kind of thing...like you said ....PRODUCTION.

there are some companies making the switch to uphill flux core mig. In fact, I recently read an article about a company that uses a welding procedure where the root pass is done downhill with a 5/32 6010, then the hot pass was done downhill using a 3/16 9010 rod..The rest of the fill passes were done using flux core mig uphill. The base metal was high strength x80 steel.

I have worked with quite a few pipeline welders and they are just like the rest of us...a lot of what they do is because it works...and they have always done it that way.

thanks very much for your question.

question...Whats the best kind of welder to use for car body panel repair & replacement...or does it depend on what ur trying to repair?

answer....Are you asking whether a mig or tig welder is best? or what brand of mig welder is best? If you are an accomplished tig welder, and have the funds for a machine, I think thats the best. Less grinding, less heat, etc... but if you are asking about what brand of mig welder is best I think your best bet is a lincoln 110v mig with 75/25 argon/co2 gas and .023" e70s6 wire. Normally I recommend Miller welding machines but for price, value and performance all considered, the little lincoln machines are really a good value. you can easily score one on Ebay or Craigslist for less than 300 bones.

thanks for your question.

your question is.... How do I make a test coupon for 7018 stick and for the mig with argonco2 mix. I know that 3/4" is unlimited, but how do I make and set it up. I'd like to be certified bothways and up to a vertical cert-3g?

Answer....qualification limitations are different depending on which welding code or spec your are certifying to. AWS D1.1 for example requires using a 1 inch thick plate for a groove weld in order to have an unlimited thickness range on groove welds. Welding a 3/8" plate will qualify up to 3/4" on groove welds but goes to unlimited on fillets. Here is the joint setup for the AWS D1.1 3/8 plate test : 3/8 thick by 3" by 7" A36 or plate with a 22 1/2 degree bevel. gap it 1/4" and use a 1/4" thick by 3 inch wide backing. weld it in the 3g vertical position ( 3g qualifies for flat, hor, and vert. if you want to be qualified in all positions, do a 3g and a 4g). For mig you might want to use a 30-37 1/2 degree bevel with no backing . It gets kind of complicated on MIG because most codes are leary of mig with short circuit transfer (GMAW-S) and require you to qualify the procedure as well as the welder. Whereas for the 7018, there are prequalified procedures.

Where I work, we have some AWS D1.1 requirements to live by and we test on stick and mig using 22 and a half degree bevel for the stick and 37 and a half degree bevel for the mig. The stick is with backing and the mig is open butt . The Vertical mig is done with a 1/8 open root gap welded downhill. The rest of the vertical joint is done uphill. We require the welder to pass both 3g vertical and 4g overhead in order to be certified in the process.

Here's the thing: if you just want a certification paper for bragging rights or to help you get a job, just locate a AWS accredited test facility near you and pick a test that is not too difficult and knock it out. I have only had a few jobs that ever recognized a previous certification. they always made me test to their specs and the test was different every time.

here's a link to a list of AWS accredited test facilities and good luck with your tests link to accredited aws test facilites If there are not test facilities convenient to you, test coupons can be ordered from Triangle Engineering welding test plates for around 20 bucks per test. (for the 3/8 plate)

PS. feel free to email me if you have more questions

Jody

www.weldingtipsandtricks.com

Question: I was wondering Im just starting tig welding and wanted to know How to get the beads? Like do I move the torch or do I move the welding filler rod to create my beads? Please e mail me back and let me know.

--------------------------

answer....The way I teach TIG is to create a puddle about 4 to 6 times as big as the thickness of what you are welding.(up to a max of about 3/8") then dip some rod into the puddle and take it back out. Now move torch ahead about 1/8" and stop and dip some rod again. The bead will be made by doing this over and over:

move the torch, add some rod, move the torch, add some rod, etc..

Once you get some experience under your belt, you may find other tig welding techniques that you like better but I have found this works the best for beginners because you are using one hand at a time.

good luck

Question: I was just wondering if you had a uphill vertical welding with stick video or know of any? I'm currently in a welding school and i just acquired my flat position and horizontal position tickets, so I'm on to vertical and overhead now. Thanks

answer....Don’t have a stick video done yet.... But here are some pointers: For both Vertical and overhead, Keep a real tight arc length and watch your rod angle....try to keep it pretty much straight in. For vertical uphill 7018, I like the same technique as on the YOUTUBE video for mig uphill. Just pause on the sides a little longer to fill undercut and don't spend much time across the middle of the puddle. I run overhead almost as hot as I run flat. I keep the rod tight in the puddle and don’t use much angle. The arc force helps the bead to flatten out.

question: I am going to be taking a tig test on 321 stainless, inconel, and hastelloy.It is on 24 or 26 gauge material. Never done any welding on metal that thin before. Have done stainless and inconel welding, but not hastelloy, and not that thin. Any help would be greatly appreciated. By the way it is a 1g plate test.

answer.....Well , you are in luck. I have a lot to say about welding this stuff. Sounds like the test is for Aerospace work and if it is, its probably administered to the AWS D17.1 spec. If so, your test pieces should only be 5 inches long and most likely will be done in a fixture that provides argon shielding and a heat sink. The Hastelloy is probably Hastelloy X but I am just guessing. For these thicknesses (.019-.025") there are some tips and tricks to keep in mind:

-you will only need around 12-18 amps so don't set the machine much higher than around 30

-don't use a steep filler rod angle and feed the rod gently or you will poke filler rod right thru the back side

-add a little extra filler on the end tacks so you wont melt them away when starting or finishing

-if you get a tig machine with A/C balance control make sure to set it to balanced. (I know this sounds crazy but miller syncrowave 250's start really hot if you forget to do this...even on DCEN)

-don't set the fixture shielding gas too high. most fixtures used for these type of tests have a very small argon trough with one row of flow holes. too much flow will disturb your torch gas on the ends.

-a bead width of 4 times the thickness of the plates (in this case around .080") will penetrate as long as you don't add excessive filler metal.

-keep the hot tip of the filler rod shielded by torch gas at all times.

-if the fixture allows, locate the chill bar hold-down plates very close to the joint to prevent warpage.

-electrode should either be .040" or 1/16". use a good sharp one and keep it clean...hold a tight arc (no more than electrode size)

I wish you luck and you are more than welcome to ask more questions by just replying to this email. I would really like to know more .I work in Aerospace and am very familiar with this kind of testing.

thanks

Jody, thank you for the advice! My overall visual was great on all three metals!!! I actually surprised myself. Just waiting for the feedback on the x-ray and FPI test.

Thanks again!

That just makes my day!..About 90% of the time on these metals and thicknesss, if visual is good, all else is good too.

Hey Jody, got my results back on my weld test. I passed the 321 Stainless and the Cobalt, but busted out on the Hastelloy X. He told me that I passed the x-ray on the Hast-X but he said that I had surface porosity on the sides of the weld. I have heard that you can "drag" the torch on Hast-X to keep from getting any purosity. When I welded it, I use a ocelating or side to side motion. Anymore advice? My thanks,

What was the thickness of the hast x? Personally , if it is as thin as you mentioned previously, I would not use a side to side motion. (but theres always more than one way to be right) I would just follow the joint in a straight line. Just create a puddle about 4 times as big as the thickness of what you are welding.( and then dip some rod into the puddle and take it back out, then move torch ahead about 1/16" and stop and dip some rod again. Do this over and over : about once per second .....move the torch, add some rod, move the torch, add some rod, etc.. Sounds like you have a pipe welding background..,So do I. I had to leave the weave behind for this thin stuff.

As far as the porosity goes, how did you clean the metal? 2 main things that i see all the time are:

1. not filing the sheared edge of the joint (use a clean file.. not any abrasive, or sanding disc, )

2. cleaning the weld area with the wrong stuff...3m scotchbrite pads and abrasive tootsie roll type sanders are the 2 worst I have seen for causing porosity.

If it was surface porosity, looks like they would have seen it on the visual.

Hast x doesnt usually present porosity issues. I have to believe it was in the cleaning method. Also going just a little slower sometimes helps on porosity cause it has more time to outgas.

hope this helps and good luck on the retest.

PS. the more you can tell me the better.

regards, Jody

question, what percent is the nickel silver content of welco 14fc nickel silver welding rods?

I could not find the answer but l left a message for Harris-Welco and if they answer, I will send you the info. Are you using them for brazing or just trying to get a good scrap price? Thanks for submitting your question.

Jody

Jody, thanks for answering This may be Interesting or helpful to you.. We interstatesurplus.com have a bussines arangement with a large welding supply company here in the south east they have been buying out small company 2-20 branches for their customer list, we have been getting all of their inventories and getting all of the larger company's dead inventories which has set on the shelf for 1 year (thats what they call dead inventory) all of it is BRAND NEW which in turn we are able to sell for half price or less But we have to find out what it cost and what its used for some of the precious metal fillers we may or may not scrap, but we still need to find out what it is.. if you need any welding supplys of any thing else for that matter let me know you cant buy it any cheaper any where else in THE WORLD. look at our website and our ebay store interstate industrial surplus we buy out plants, factories, and inventory's in the carolinas, we never know what we might have next, but thanks again Rob Gainey interstate surplus 704-827-6449

Rob, This is what I received from Harris although I am not sure its completely exact because it was listed welco 14, 17, and 170. (the fc you referenced indicates flux coated) NOMINAL CHEMICAL COMPOSITION of Welco 14 fc:

Copper-- 46 %-50 % Silicon --- 3.5 % max Nickel ---- 9 %-11 % Silver ---- .07 % Manganese---- 1.5 max Iron ---- 1.5% max Tin --- 3 % max Zinc ---- Remainder

I would be interested in putting your email on my website along with your phone number if you dont object. I know there is lot of consolidation in the welding biz. in the last couple of years I went from dealing with Holox,to Linde GAS, to Airgas.....to "what a pain the ass."

Question: I am looking for the best welding school to attend. I currently live in Idaho, but I'm willing to go anywhere in the U.S. in order to receive the best welding instruction. Based on accreditations, Tulsa Welding School and Hobart Institute of Welding Technology look like the best options. However, I'm looking for a professional opinion on which school is THE BEST WELDING SCHOOL IN THE UNITED STATES. Please help me out!

answer...I don't know a lot about Tulsa welding school other than they also have a location in Jacksonville, FL. Tulsa has been the home of Pipeline welders for years and I have worked with quite a few welders from local 798. I am sure their program is solid but I can’t speak with any firsthand knowledge about the school. But I am very familiar with Hobart. In fact, I visited Hobart for the first time around 2001. And then again in 2007. I have to say I am pretty impressed with the school. But..It’s in a quiet little town called Troy Ohio so if night life is important to you, it’s not going to happen in Troy. I believe their curriculum is as solid as they come and I am completely impressed with Ron Scott-President. (Ron went through the whole program twice; once right handed and once left handed) Since he does the hiring of instructors, I am confident that Hobart has some of the best instructors in the world. But here's where the decision lies: What programs to take. There are lots of choices. I will say this. If you can do it, get all you can get. I mean take Stick, Mig, Flux Core, Tig, Learn to weld pipe. And when you think you’re done, take the Tig course as well as the Titanium Tig course. That will open up your options to work in everything from Aviation to Nuclear power house construction. Hobart offers a Tig course that is 2 weeks long and that allows you to then take a titanium Tig course. Just being able to say you can weld aluminum and titanium will open a lot of doors for you. Can you imagine being proficient in Stick, Mig, and Tig, on Pipe and sheet metal and also being able to Tig weld aluminum and titanium???

I hope this helps. You seem ambitious, and I wish you all the good fortune in the world.

I have a dynasty 200 miller and weld mostly light gauge 4130 steel. The puddle seems to splatter and I get porosity. It only happens sometimes, other times, exact same setup, it is smooth and calm puddle and almost effortless. What is up?

answer..... If it is 4130 tubing you are welding, when you seal up the joint, often times pressure builds up and blows a hole and disrupts the gas shielding and causes porosity. You can either drill a small vent hole in a place that will allow or stop right before you seal it up and let cool for a minute before coming back and hitting it quick to close it up...or 309 stainless rod will let you overcome the porosity..if the application will allow for this. I had a bit of a shielding issue when I first got my Miller Dynasty 200 also. It cleared up and I suspect my argon was to blame. I am not convinced the smaller owners bottles are as pure as the full size rentals. Since your problem is hit and miss, its probably not the argon.

I like to use a gas lens setup with a #7 (7/16) cup. around 15-20 cfh is plenty . electrode extension around 3/8". too much argon flow with a small cup is as bad as not enough argon.

I would like to know if any of this rings true..if not, can you give me more information?

Question... My MIG welding looks bad, I mean really bad...kind of like Crow shit on a barb wire fence. Do I suck? Should I give up? Every now and then I get a good weld...could my welder be the problem? Are there any exersices that you would recommend for practicing?

Answer... I would like to know more details like: gas type, gas shielded or flux core, size and type of wire and whether you are welding with a 110v or 220 volt machine..But I will go ahead and tell you what I think are the 2 main things peple get wrong in mig welding.

1. Bad ground. Sounds simple I know but the ground clamps I see on machines these days suck. It appears the companies are trying to save a dime on the ground clamp to stay competitive with China. Problem is your wire feeder doesnt care that you have poor ground and just keeps on pumping wire. This will get you off to a bad start and its hard to recover. In short, makes the weld look like ass. ( or like your barbed wire metaphor). get a better ground clamp or find a piece of copper to slip under one of the jaws. Also, grind a small area clean and attache the clamp there. Paint or mill scale will not allow for a good ground.

2. Way too much stickout.(distance from the arc to the contact tip) Check out your mig gun. if the contact tip is recessed way back in the nozzle, thats a problem. Adjust the mig nozzle so that it is flush with the tip, or if the mig nozzle is not adjustable,Even if you have to trim the nozzle with a hack saw, it will weld better immediately with only about a half inch stickout.

As far as practice goes, if you can get a piece of scrap angle iron thats a good start. Once you fix your stickout problem, and ground problem, just practice stacking beads halfway on top of one another.

good luck

Is it better to Mig uphill or downhill?

What a loaded question! Here is my take on it: for ¼” thick and thicker, uphill is better. Now there are all kinds of exceptions here like open butt roots on pipe welds etc… but it’s a rule of thumb anyway. If the weld is being done to a welding code, that will dictate whether uphill or downhill.

Which Mig welding technique is better, Pushing or Pulling?

Don’t get me started… don’t even get me started! I think this welding question got started because some welders working in a railroad boxcar factory where they were using spray transfer mig got to shooting the breeze with a welding instructor teaching short circuit/short arc welding who read in a text book that pulling the puddle got better penetration. Here’s my take on it: Who gives a rat’s ass?! You know what’s hard to argue with? Results! that’s what. So when someone passes a welding test using a push angle, while at the same time another welder fails the test that he pulled, how do you argue that pulling is the way to go? Please!. I have tested hundreds of welds doing both and they all pass if done right.

Do I really need pure tungsten for Tig welding aluminum?

the answer to this welding question is No. Hell No. pure tungsten is crap! It makes a nice pretty ball on the end. That’s about it. It won’t carry much current before said ball quivers and dumps in the weld. Is that worth a nice pretty ball? I use 2% thoriated for everything. That’s right…everything.

Why am I getting porosity?

Odds are you didn’t clean the metal. But there are other possibilities. Porosity is gas bubbles plain and simple. But what causes them? Oxidation, paint, oil, grease, lack of shielding from the atmosphere, and about a hundred other things depending on what process your are using and what metal you are welding.

Why Does Tig welding have to be so slow?

What kind of a welding question is that? Tig is always slower if you do it by the book. But why not think outside the box and break the rules? On some metals you can weld pretty fast. Especially if you consider there is no cleanup afterwards.

How do you weld clear anodized aluminum tubing ?

Most guys that weld tuna towers and marine parts can give you some tips on this. Most of them hook up a switch on the torch and pulse weld manually by going from on to off again and again slightly overlapping puddles. This seems to break though the anodized coating. Boat owners will not put up with ugly welds or welds with a bunch of sanding or wire brush marks.

More welding questions...

Which rod is the best one for the job?

That’s a really broad question. But here is some good basic information: Carbon steel? But you are not sure exactly which grade? , use e70s2, 3, 4 or 6

Stainless? But not sure which grade? use er308L

Aluminum but not sure what alloy? use 4043

Steel to copper? Silicon bronze

Cast iron? Nickel rod

Carbon steel to stainless steel? ER 309 or inconel 625 or Hastelloy W

If the weld is critical, you need to find out exactly what you are welding and use substantiated engineering recommendations for welding rod used.

How can I tell what type metal I am working on?

There are a few good ways to get an idea of what metal type you are dealing with. First off use a magnet. If the metal is magnetic it is either carbon steel, cast iron, cast steel, a magnetic grade of stainless steel or severely cold worked stainless steel, or pure nickel. Not magnetic? Could be practically anything else. Aluminum, titanium magnesium, copper, cobalt, nickel alloy? Spark test is another way to narrow it down, but it takes a lot of practice.

Who makes the best machines?

Now that is a welding question to my liking... Miller because all of them tear up eventually and miller will treat you right when that happens.

Why do I need alternating current for Tig aluminum?

The positive half of the alternating current cycle breaks up the aluminum oxide on the surface of all aluminum.

What are the best and worst jobs?

The best job I ever had welding was welding aircraft engine parts in an air conditioned shop. The worst welding job I had was knee deep in coal fly-ash in a Power-Plant Boiler in Alabama.

How do I get certified?

One of the most common welding questions ever... Look on the American Welding Society site for accredited test facilities More welding questions...

American Welding Society site for accredited test facilities and give the one closest to you a call. There are a lot of other ways but this is the simplest.

What is the best way to weld aluminum, mig or Tig?

1/8” and under TIG is the bomb…Over 1/8” and MIG might be better. Notice I said “might be better” if it’s a dirty casting I would go with TIG and just preheat it to around 200f.

Which is better flux core or bare wire?

Apples and Oranges. Flux core is not as good on really thin sheet metal like you find on car bodies. But it penetrates better so if you are pushing the limit while using a 115 volt mig welding machine, flux core can get you over the hump. Also for welding outside, some flux core wires don’t need shielding gas.

I heard you can’t weld cast aluminum. Is that true? As long as its not one of the unweldable 7000 series, you can weld it. Most aluminum castings are 355, 356, or 357 alloys and are readily weldable using 4043 rod. But Honestly, 4047 rod works better and flows like wine.

What is the best all around Tig rod for dissimilar metals? 4043 for aluminum, 309 stainless for stainless to carbon steel or 300 series to 400 series, Hastelloy W when you know its steel but you are not sure exactly what.

Can you weld pot metal? If so how? Yes you can. Use Aladdin 3 in 1 aluminum zinc alloy or durafix rods . Tig weld on a/c and just when it starts to run good , get off of it or it will completely melt and fall on your toes. Seriously, weld it in really short spurts.

How do you know what to set the amperage for a stick rod? For a starting point about 30 amps for every 1/32” of diameter if you are welding flat and the metal is pretty thick. Less for vertical uphill.

Can you stick weld stainless steel? Yes, but if it is out of position, you had better be a pretty good stick welder. My arms are full of scars from stainless stick welding, from when I was dumb but tough. And a slow learner

TIG Welding Questions

Why choose an inverter Tig welding machine? Because they are bad ass! Not a good enough reason? Ok, Portable, (my Miller dynasty 200dx only weighs about 40 pounds) Pulsing… my miller dynasty 200dx can pulse 499 times per second. While you might think to yourself , that is so fast it’s like no pulse, you would be wrong. There are plenty more reasons to choose an inverter. If you have more questions submit them on the form and I will personally answer them.

More welding questions...

What is the best all around tungsten electrode? 2% thoriated. Now here is the disclaimer…I am not saying it is safe, just the best. My personal opinion is that because I don’t make a habit of snorting electrode grinding dust, I am ok.

What are the best all around Tig rods? 4043 for aluminum, 4047 for aluminum castings, 309 stainless for stainless to carbon steel or 300 series to 400 series, Hastelloy W when you know its steel but you are not sure exactly what.

Can you Tig weld aluminum on DC reverse polarity? Yep, but you need a bigger electrode and helium helps, I wouldn’t try it on anything thicker than 1/8”

Can you Tig weld aluminum on DC straight polarity? Yep, buy you need high purity straight helium…not the stuff you fill balloons with…and the aluminum has to be pretty clean. This is not the way to weld a bikers Harley crankcase.

What is the best Tig welding machine? This is a Ford Chevy thing. I like Miller. But what I really like is the Miller people that I know will help me when I need help.

MIG Welding Questions

More welding questions...

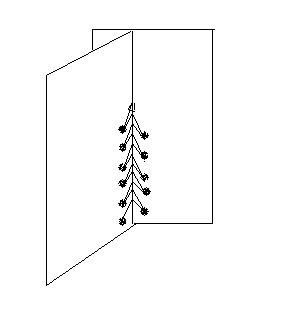

What is the trick to mig welding uphill? I have found using an upside down V technique to work well to keep the bead flat and penetrate all the way into the corner of a joint. Look at the diagram below to see what I mean.

What's wrong with mig welding downhill? Click on this link Mig Welding LOF (lack of fusion ) to see a cross section of a mig weld on 3/8” thick hot rolled A36 material. If you are welding sheet metal downhill is the way to go. Or if you are welding metal less than ¼” thick and the design is not critical, downhill might be ok. It is definitely easier but easier is not always better.

Is 75/25 argon co2 better than straight co2? Honestly, for most applications straight co2 would be fine. I like the 75/25 because it lets you run a soft arc when you turn down the machine for really thing stuff.

Why does my mig welding machine stutter when I start welding? Bad ground clamp… take a look at it and see what I mean. Ground clamps have gotten chincy and in mig welding it critical to have a good clamp. Buy a really good one and watch your welding improve.

Who makes the best mig welding machines? I like Miller. But For 115v mig machines, Lincoln is cheaper and pretty good.

Stick Welding Questions

Question: Do they make stick electrodes for welding aluminum..I dont have a tig welding machine?

It is possible and they do make stick electrodes for welding aluminum. But.... it’s kind of a last resort. The rods have to be kept really dry in a rod oven or used right out of the box. Porosity is a problem and trapping slag is also a problem. Especially if you are trying to fill a misdrilled hole. For a simple fillet weld in the flat or horizontal position, they work ok for non critical applications. One thing is for sure, aluminum Stick electrodes take some getting used to. They burn off really fast. You can get the rods at this website: http://store.cyberweld.com/alel40.html

Question: When welding in the vertical position with a 7018 rod, what angle do you want to maintain if you’re traveling from the bottom to the top?

Anything from "dead nuts straight in" to 20 degrees push will work. People have a tendency to get more angle as the rod burns down so I think if you attempt to hold the rod straight in; you end up having a little angle without even realizing it. You definitely do not want to have any drag angle when welding vertical uphill

Does anyone really stick weld anymore? You would be surprised. Pipe welds made in the field, structural welds like on bridges and high rises, all are largely made with stick welding.

Who makes the best stick welders? Lincoln or Miller take your pick... It really boils down to customer support and service

Can you weld downhill with stick? Pipeline welds are mostly made downhill with 6010 or 7010 rods. One of the best downhill setups I have found is a Lincoln a/c 225 buzz box with 6011 rods.

What is better, 6010 or 7018? As long as you keep your 7018 rods in rod oven, their welds will always be stronger and less likely to crack. 6010 penetrates a lot deeper.

I keep my stick rods dry in an old fridge with a 100 watt bulb inside. Is that cool? if you are on the farm that might be ok. But For critical welds, a rod oven is the way to go, If you don’t have a rod oven, buy the 10 lb sealed packs and don’t open them until you are ready to use.

tig welding gas shielding remote amperage control for tig welding choosing the right shielding gas for tig tig welding info tig welding rods tungsten electrodes tig torch