Tig Welding Aluminum and How to make a Simple prop stand

Video Shows 7 Tips for TIG Welding Aluminum

- HOME

- TIG WELDING ALUMINUM

- How to Tig Aluminum

- Tig Welding Aluminum

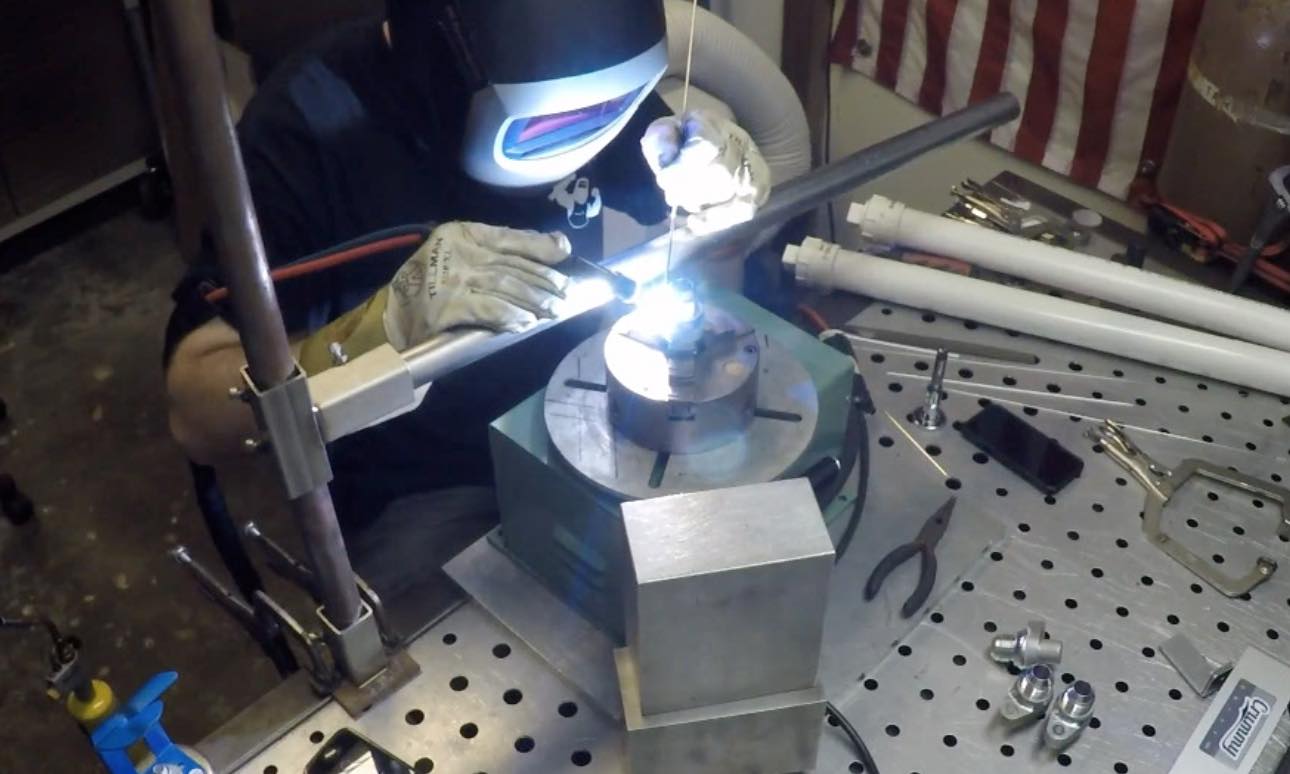

This weekly video is about Tig welding Aluminum Parts on a turntable, Preheat, and how to make a simple prop stand that can be used for welding parts on a turntable or for a place to prop your hand on long straight welds.

see more tig welding aluminum videos or go to the main TIG welding page

Why Preheat?

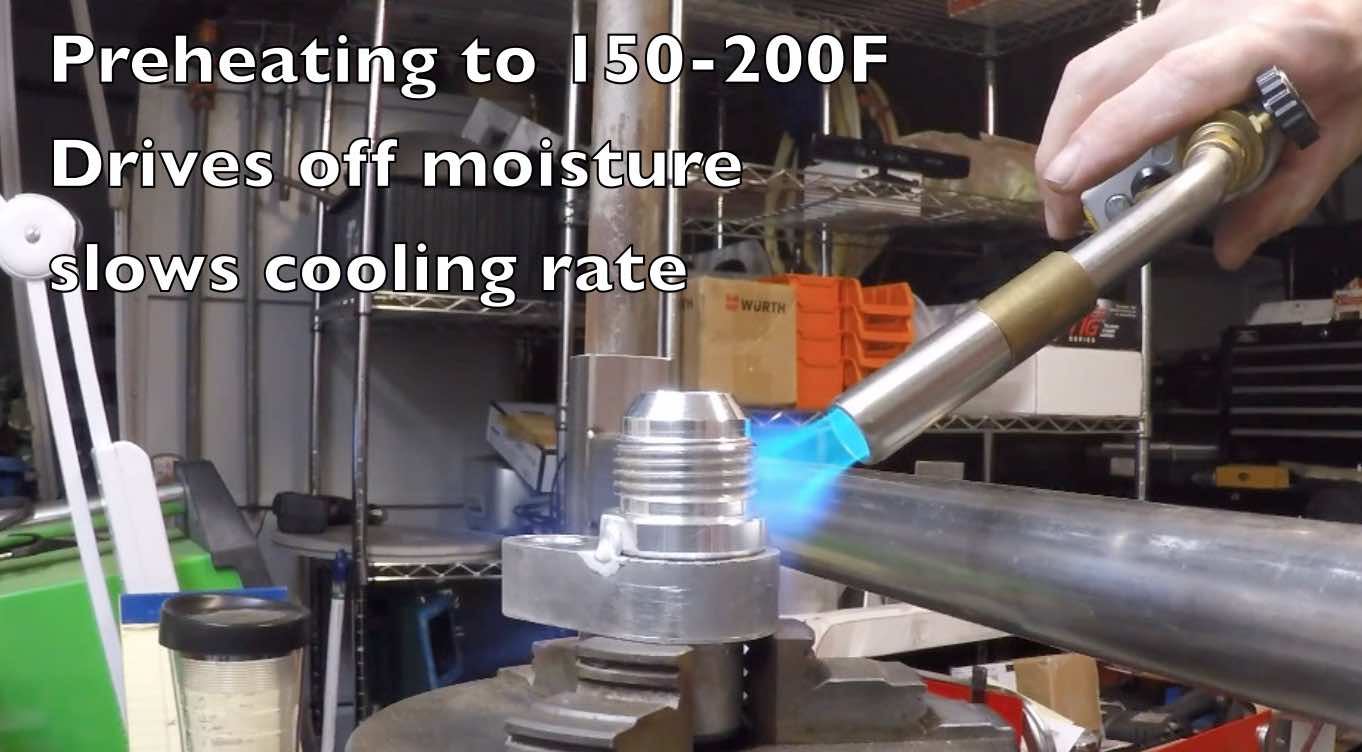

Preheating Aluminum accomplishes 3 things...

- drives off moisture

- slows cooling rate

- lessens thermal shock

When you first light up on thick cold aluminum with a tig torch, you will most likely see some small porosity.

Once the metal heats up, porosity usually goes away.

Since porosity is gas bubbles...and when those gas bubbles dont have time to escape due to fast cooling rates, a preheat really helps to eliminate porosity in aluminum.

So how much of a preheat is needed?

Usually about 200f does the job.

...much higher than that and you risk compromising the mechanical properties of the aluminum.

A 200f degree preheat may not sound like much, but it can make a big difference.

Why use 4943 Aluminum Filler rod instead of 4043 for tig welding aluminum?

For years 4043 was the main standard in aluminum filler rods for welding 3003, 6061, and aluminum castings.

But now there is a relatively new filler rod available ...4943.

4943 flows better than 4043 and has better mechanical properties...and its also heat treatable.

I think 4943 it will gradually replace 4043.

I did a weld repair on a cast aluminum outboard jet pump a while back and used 4043 for the actual repair and if worked out fine...but a few days later, I got a sample of 4943 and used it to do some arc shots for that video and I was very impressed at how it flowed on dirty oil soaked aluminum.

(but my favorite rod for cast aluminum is still 4047)

Making a DIY Prop Stand for turntable welds and for long runs

For the small amount of time and material it takes, I highly recommend making a prop stand for turntable parts and even for making long straight runs on parts.

Roy and I both take in work on round parts and we both have turntables to make those jobs go quicker and better.

A prop stand is worth its weight in gold.

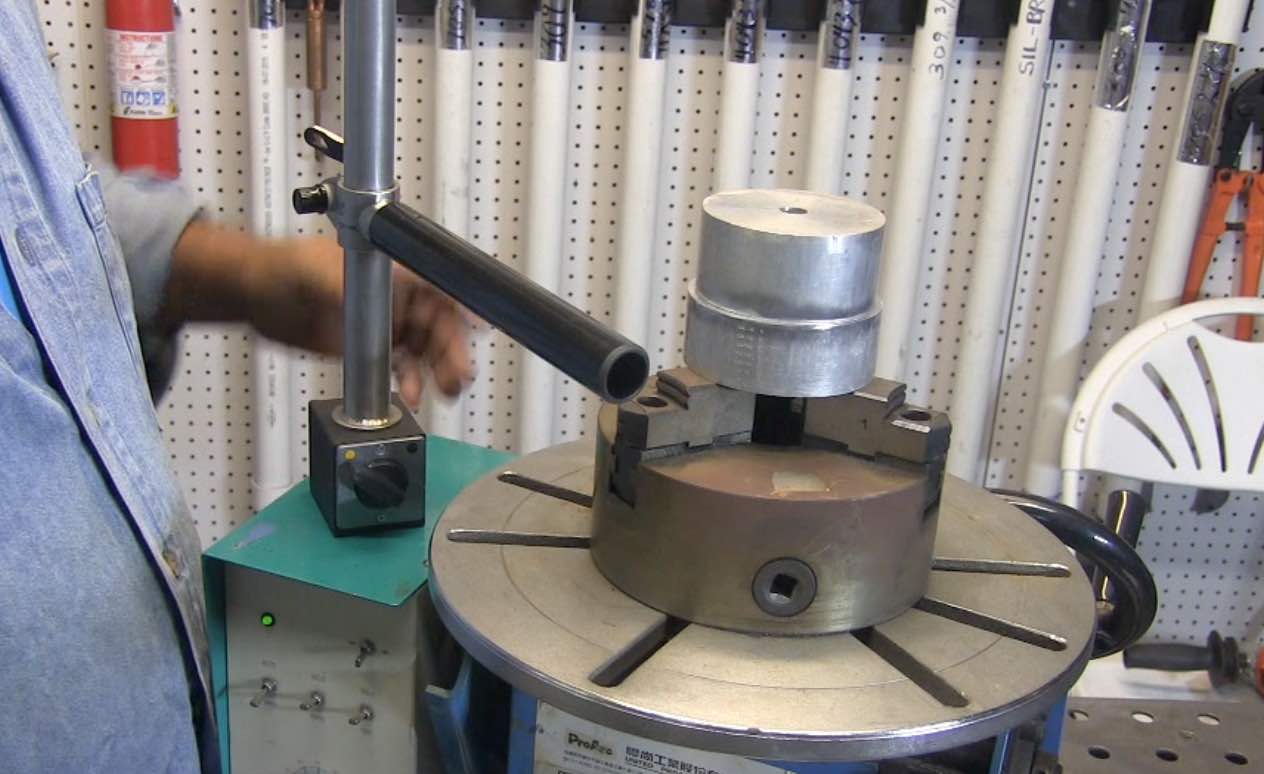

Steady Rest with Magnetic base

If you are not in the mood to build your own prop stand, you can just order one.

Bill Ellert sent me his "Steady Rest" product with a magnetic base.

Its the same type of setup a machinist would use to hold a dial indicator.

I found it very useful and easy to use.

You can see Bills Steady Rest at wcedesigns.com

For more detailed videos and information on tig welding cast aluminum visit welderskills.com