TIG Welding 50 parts using 3 different Tig Welders

- HOME

- TIG WELDING

- Tig Welding

If you are still using the standard TIG cups and hardware that came with your machine or TIG torch, I can just about guarantee you will get better results if you upgrade to a weldmonger® stubby gas lens kit.

I just finished TIG welding an order of 50 parts for my machinist friend.

And

I used three different Tig welders to complete the job. Mainly because I

make YouTube videos about welding and I wanted to make it interesting

and also get some time on the AHP tig machine before sending it off to

the winner of the giveaway

This is one of those jobs where the

machinist does some work then gives the parts to me, I do some welding

then give the parts back to the machinist so he can do some machining,

then I get the parts back again for some more welding etc.

TIG Welder 1...AHP alpha tig 200x

The first work I did was using the ahp alpha tig 200 x.

It comes with a torch switch and a foot pedal but I used the torch switch for quick tack welding at around 195 to 200 A

Torch switches are handy for tack welding and it also came in handy for welding on the turntable.

I

welded the first run of parts somewhere at around 180 amps and using 1

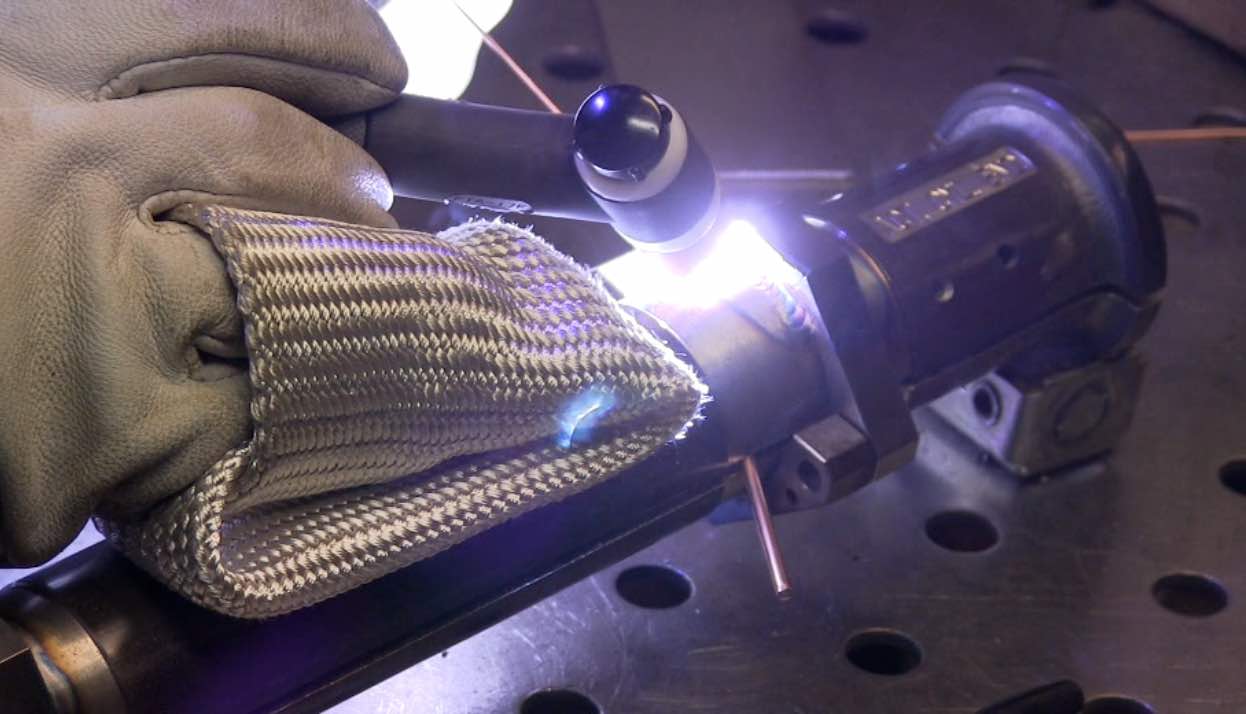

to 2 pulses per second just propping my finger on the part using a TIG

finger XL...

And on the other end that had a flange, I walked the cup using a number 6 cup using about 15 to 20 CFH of argon flow.

I

was welding at such a high amperage with an air cooled 150 amp torch

that it got really hot and that caused the Collet to get soft and

corkscrew. So I switched over to a water cooled set up using an

TIG welder 2...EVERLAST 210 EXT machine and the Weldcraft 280 torch

A water cooled torch is the way to go for high amperage repetitive parts.

Without a water cooled torch, you are limited on amperage and how long you can weld without the torch getting too hot to hold.

So after the first run of 10 or 20 parts, I switched over to a water cooled weldcraft wp280 tig torch.

It uses small 2 series hardware and so I put a #6 gas lens on it.

Then I set up my welding lathe. (a welding lathe typically has a turntable, a torch holder, and tailstock...I got mine used off ebay)...

It has a turntable with the three jaw chuck a tail stock that is air operated and an air operated torch holder too.

It takes a few minutes to set up and get dialed in but man is it worth it for a job like this.

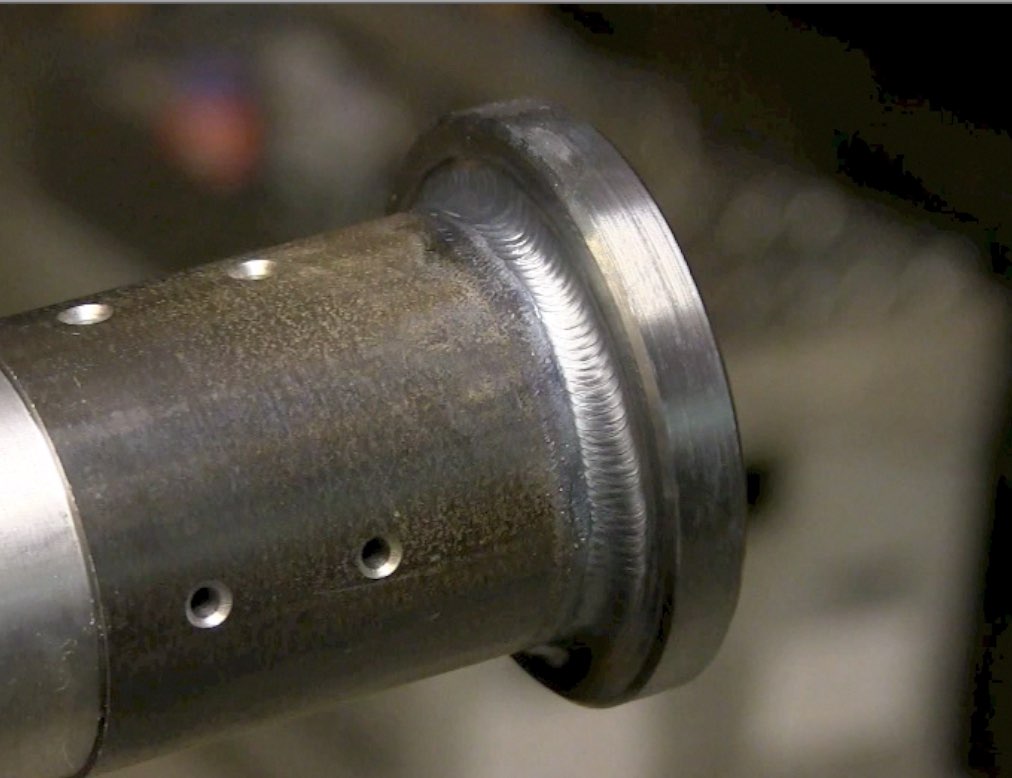

My final optimum settings using the Everlast 210ext were 210 A 50% pulse on time 40% background. for the end without the flange.

And for some of the flange welds I just walked the cup at around 180 A using at 3/32 rod...for others I used the torch holder and used 210 amps with 2 pulses per second and both pulse and background set to 60%.

Lincoln Square Wave TIG 200

'The final welds were hinge pieces and I used the Lincoln SquareWave 200 at 140-160 amps.

I had a Lincoln 17 style air cooled torch again for these welds but since the welds were short runs, it didnt get terribly hot.

for the most part, I set the machine to 160 amps but also went as low as 140 amps using .045" (1.1mm) er70s2 wire.

These parts got really hot with 8 total welds so using a TIG Finger XL really helped to give me a place to prop as I rotated the torch to keep the angle good.