Stick Welding Question

On Sat Apr 19 10:08:51 2008, the following question was submitted from the "Stick welding questions" on weldingtipsandtricks.com:

------------------------------

How do you tell when you're welding too hot? People can tell me that I am but they don't really know how they tell. And also I saw you said that 7024 can be used with a dragging technique, but I didn't see it for 7018. I was taught that you use a dragging technique with 7018

Reply to Stick Welding Question

Answer to Stick welding question,

One clue that you are welding too hot is when things are just out of control. Kind of like when you are driving a car too fast in the rain. But I would say for Stick welding in the flat position, that no matter how hot you are welding, if you are not getting undercut and the weld looks good, you are probably ok. But if you are welding out of position like a vertical uphill weld, welding too hot will be pretty obvious. You will have undercut on the toes of the weld and the weld puddle will be too hot to control and will usually be crowned up in the middle. Another clue is if you burn a rod down to about 3 inches long and your stick welding rod is glowing red, you are too hot. The problem then is that the first half of the rod runs different than the last half. When a stick rod gets that hot it acts funny and melts at a different rate than when its not hot.

Rods are all different as to the perfect amperage setting and machines are different too.

Stick Weding Amerage rule of thumb

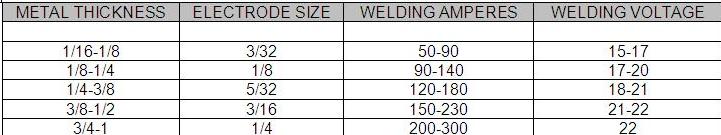

Roughly 30 amps per 1/32" of stick rod diameter will get you in the ball park. For some Stick rods, this will be a little hot. For example, 90 amps on a 3/32" 7018 will be a tad hot. The rod will probably glow before you get it used up. But for a 1/8" 7018 120 amps will work great for flat welding. The best thing to do is start with this 30 amps per 1/32" dia rod, and then get a piece of scrap metal that is roughly as thick as what you will be welding and fine tune things.

Here is a chart you can refer to also.

7018 and 7024 Stick Rods

7024 welding rods are also known as "Drag Rods". They are ony designed to be run flat or horizontal and are best run with a straight drag technique. 7024 stick welding rods have a lot of iron powder in the flux that adds to the weld. Thats why they lay down a bunch of weld fast.

7018 welding rods can also be run using a straight drag technique. They can also be manipulated with a slight weave technique or with a full on wide weave. Some welding codes limit the size of the weave due to concerns of added shrinkage sress and heat input. But that doesnt mean it wont work.

Turn an old pipe welder loose with a 7018 and he will weave 9 times out of 10.

Leave stick welding and view home page