Stainless Steel Shaft Repair using Tig overlay

Written by Jonathan Lewis - contributing author

How do you save an expensive Stainless steel shaft that has been bent and worn down?

Overlay it using TIG welding and then machine it down.

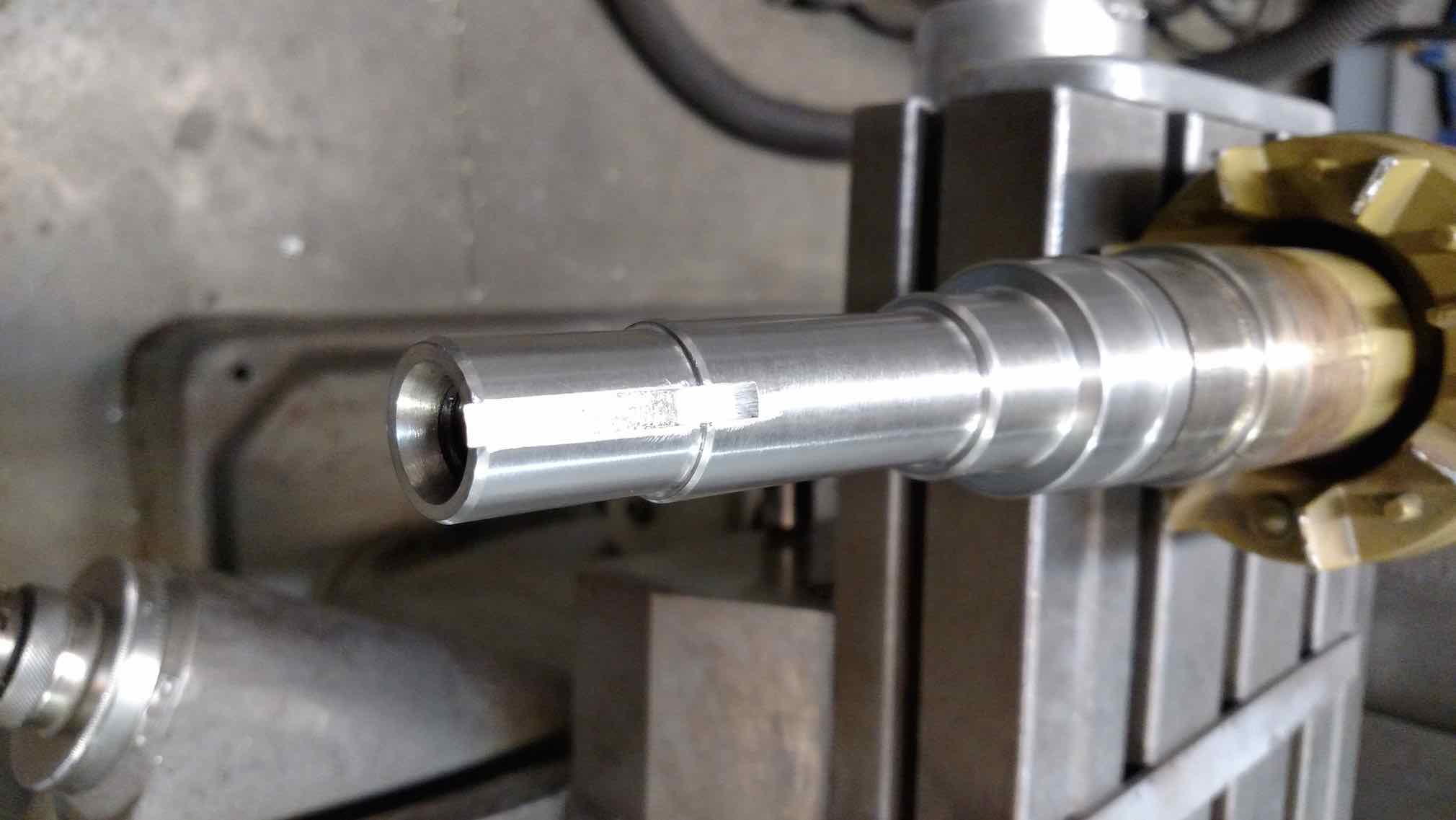

Today we are going to look at a 304 stainless steel rotor shaft that was bent, and grooved out on the seal surface in places needing to be built back up to within specifications...

There are several things to consider when doing a repair like this. What is the base material and what filler do I need to use?

- How much

overlay do I need to put on so the machinist has enough to hit the

final dimensions without trouble?

- How much overlay is too much?

- What

about interpass temperature, keeping the heat input down so the

characteristics of the SS are not ruined?

- How do I price out a job like this?

Stainless steel shaft weld repairs are pretty common

I get to do quite a few of these shaft buildups for 4D Machine in West Salem, OH and we have developed a system that works well for both of us. The shaft today was believed to be 304 Stainless Steel so 308L filler wire was selected. This is probably the most common SS filler we use. The customer needed a total of .120 “ added to the shaft to provide adequate material to hit final dimensions after machining and because the end of the shaft was actually bent and I had to fill in the key way so a new one could be cut. I choose 3/32” 308L filler because with the slower travel speed on the positioner and a consistent dipping I know using 3/32” filler I can get around .060 in one pass (.120 total for the shaft) and I would not have to put multiple passes on. This also limits the heat I put into the shaft. When I repair these shafts I normally set them in “v” blocks and turn the shaft by hand but today we selected a positioner to speed up the process and make sure we get a consistent overlay. There is also the debate of welding linearly or laterally. Welding linearly can amplify the shafts bending and caution should be used when using this method. I have done shafts in the past like this and sometimes have to redo them because I put too much heat in one spot and bent the shaft from welding. Laterally welding is preferred by me since is creates an even heating and as the shaft is rotated the pulling can be reduced.

I used a Miller Diversion 180 set around 150 amps but actually used an average of 120 amps. I used a large diameter gas lens with a #12 cup and 1/8” 2% Thoriated tungsten sharpened to a needle point. This set up has given me the best results for these shafts so far. I tried to keep the interpass temp no higher than 300 degrees F which meant that I had to let the shaft cool down quite a lot. This is important because I did not want to destroy the mechanical properties of the SS. Several things to watch out for when doing these types of repairs. When doing small diameter shafts really watch the heat input. Too much heat can bend the shaft or melt it away destroying it beyond repair. Take measurements before welding and after with a caliper to make sure you have enough filler. When in doubt add more. It is better to have too much filler on the shaft than not enough. It can be embarrassing and costly when you have to add a little more filler because you didn’t put enough on the first time. Get comfortable. I made several props and slider bars for me to rest on. This keeps me more stable when doing shafts, or any welding really, and helps keep fatigue down.

So the question we are most often asked is how to price out a job like this. Well, for these specific repairs I charge per hour instead of by the inch. This makes it fair to everyone. I get paid for the time I put into it and I don’t overcharge the customer. Also, it can be difficult sometimes to exactly calculate how many inches you will actually weld a times. Maybe you get almost done and realize there is not enough on and have to put more passes on. Getting a good idea of how much filler will build up in a pass would help if you want to charge per inch though. At the end of the day these repairs are a perfect example of #regularwelds.

to contact Jonathan Lewis...

Instagram https://instagram.com/superiorwelding/

Website http://www.superiorweldandfab.com/