TIG Brazing steel tubing with Silicon Bronze filler

GOOD PRICES ON SILICON BRONZE TIG ROD AT WELDMONGER.COM

GOOD PRICES ON SILICON BRONZE TIG ROD AT WELDMONGER.COM

This video is about pulse tig brazing steel tubing with silicon bronze filler rod....on a Star project from Precision Tube Laser company.

I also wanted to experiment with a blackening treatment to highlight and contrast the silicon bronze joints to the blackened steel.

see more videos about silicon bronze filler rod

- HOME

- TIG WELDING

- Tig Welding

- Silicon Bronze Filler

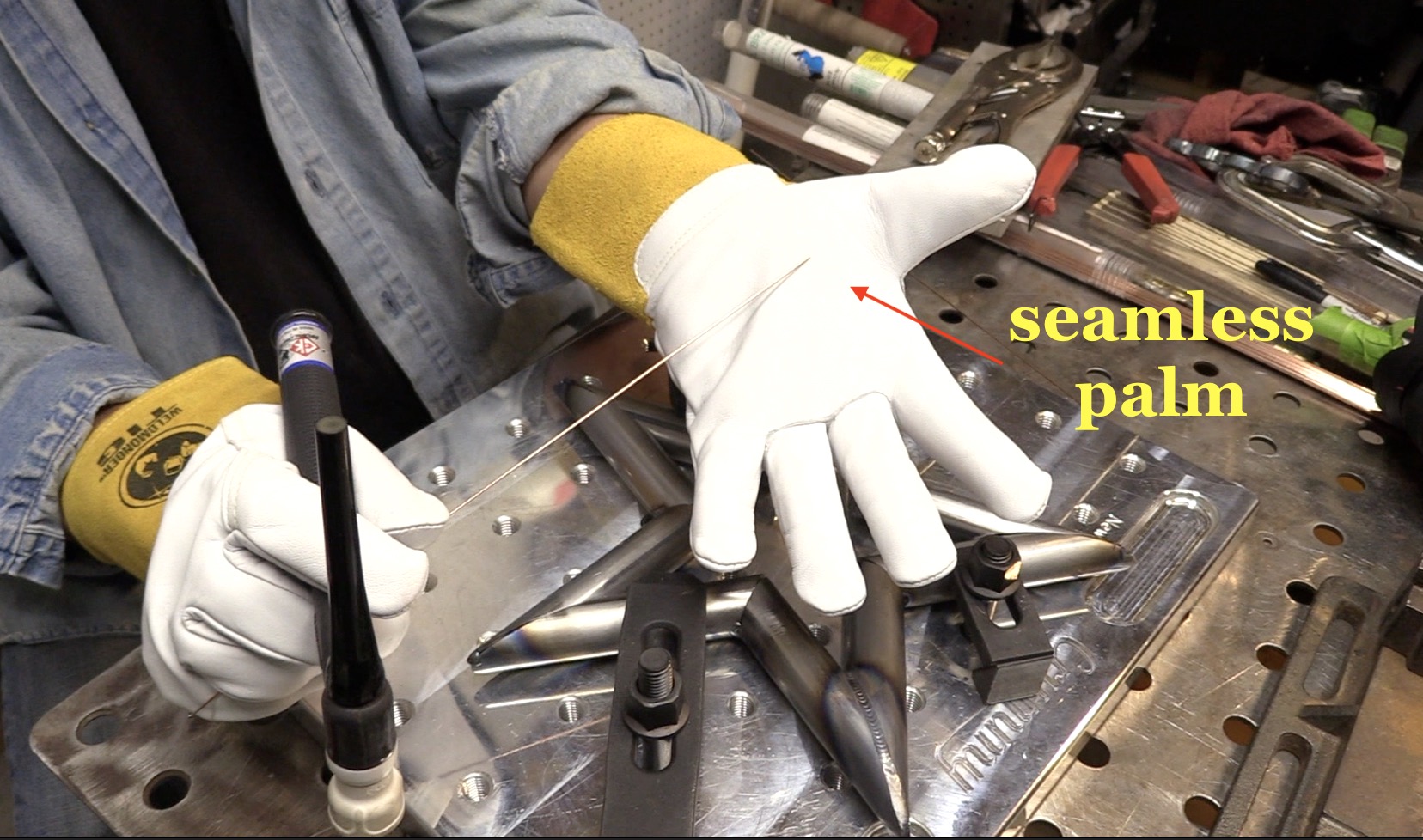

click here to learn more about my new TIG gloves

They are Both Soft and Durable

Uses for Silicon Bronze filler metal

One common use for Silicon bronze tig rod is for art work.

The bronze color of a brazed joint on steel just looks nice.

Especially on industrial furniture.

Structurally speaking, it is not usually as strong as a welded joint but when the design is right, it can be very strong....especially when joining thin wall tubing and using large fillets.

Silicon Bronze filler metal ERCuSi-A has a tensile strength of 51,000 psi and the melting point is listed as 1866F.

It is a very useful filler metal to have in the shop as it can be used to join carbon steel, stainless steel, cast iron, brass, copper, or any of these metals to each other.

I like to use Silicon bronze for temporary fixtures, prototypes, artwork, thin wall tubing, galvanized sheet, some simple cast iron repairs ( but for cast iron, I prefer aluminum brone using AC tig)

Why Pulse?

Why use pulse tig brazing?

like most tig welding, pulse settings are a nice to have feature but not absolutely necessary.

You dont need pulse in order to use silicon bronze but it helps.

Because of the low melting point of silbro filler metal, it can be very runny and can run or sag when overheated.

Pulse tig brazing just helps the puddle to momentarily solidify in the same way a fast freeze electrode like a 6010 works.

Pulse settings

I have tried a lot of different pulse settings.

I settled on 2 pps (pulses per second) because it was easy on my eyes and it seemed to work and make a nice ripple pattern.

I dont use pulse all the time. But I do like to experiment with it.

I have found that I really dislike pulse settings in the 4 to 30 range.

But only because it hurts my head.

So I usually pulse from between 0.7pps to 3 pps ...or jump all the way up to 33pps and higher.

and to make things simple, I often use my rule of 33 .

33pps, 33 background, 33 pulse time.

Miller Electric recommends background current set to 25% and pulse time to 40%.

Those are considered by Miller to be "Pro settings" but anywhere close to that seems to work fine.