Mig Welding Wire Speed settings affect amperage and penetration

This mig welding video illustrates the effect that wire speed has on amperage and penetration.

I used a Lincoln power mig 210mp with .030" er70s6 wire and kept the voltage constant at 19 volts.

Shielding gas was c25 (75/25 ---argon/co2) at aroung 15-20 cfh

Powermig 210mp default settings

Lots of machines have setting charts on the inside of the wire cabinet.

Some of the newer machines also have default settings that go along with a certain thickness of metal.

I selected 10 ga carbon steel, and the machine set itself at 19 volts and 280 inches per minute for .030" wire.

So I welded the first test weld at 19 volts and 280 ipm

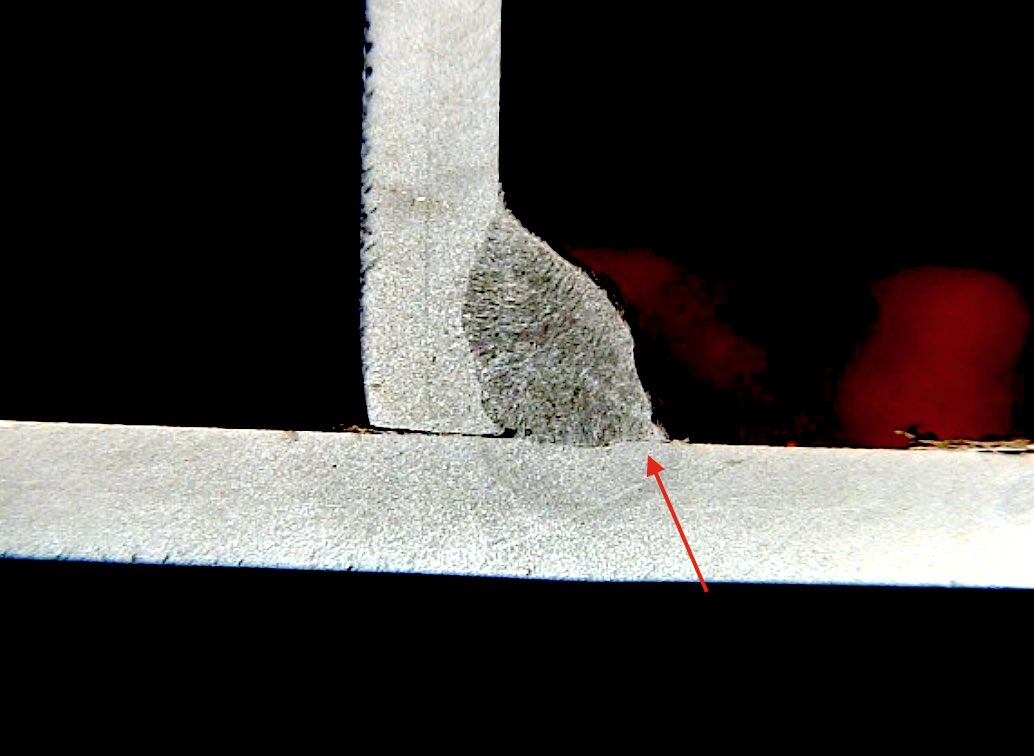

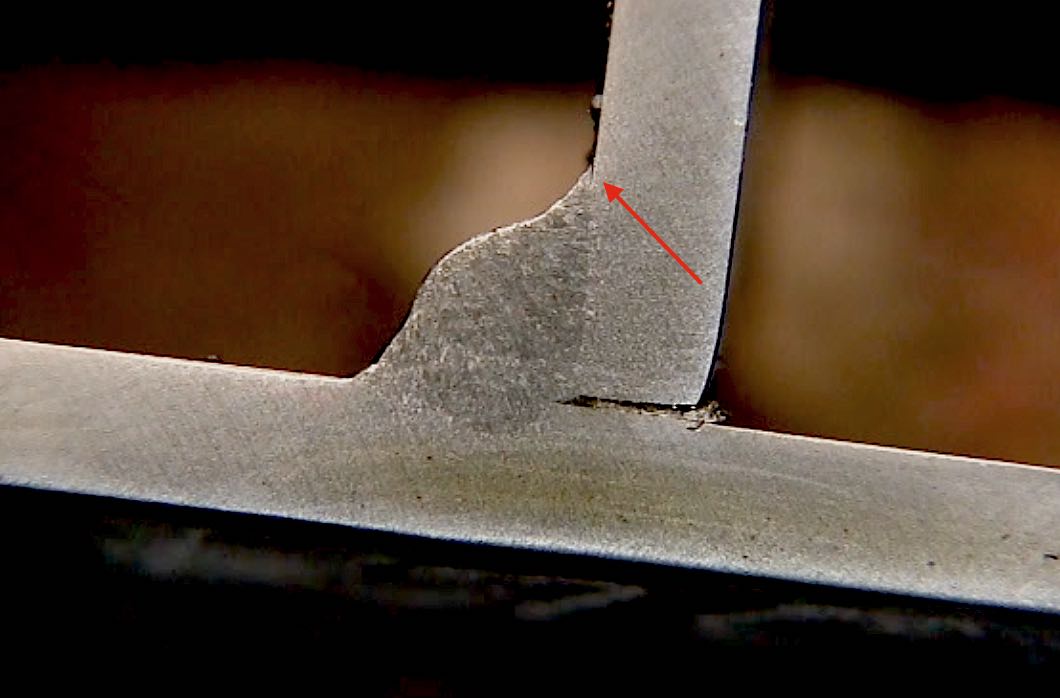

here is the macro etch result at 280ipm

The Lincoln power mig 210mp default setting of 19v and 280 ipm was pretty good.

Remember that chart settings and mig welding machine settings are intended for flat and horizontal fillet welds.

Trying to use these same settings on the same thickness going vertical uphill would make it difficult to control the puddle.

mig welding at 19 volts and 250ipm

I lowered the wire speed to 250ipm and not much changed but I did notice more small spatter.

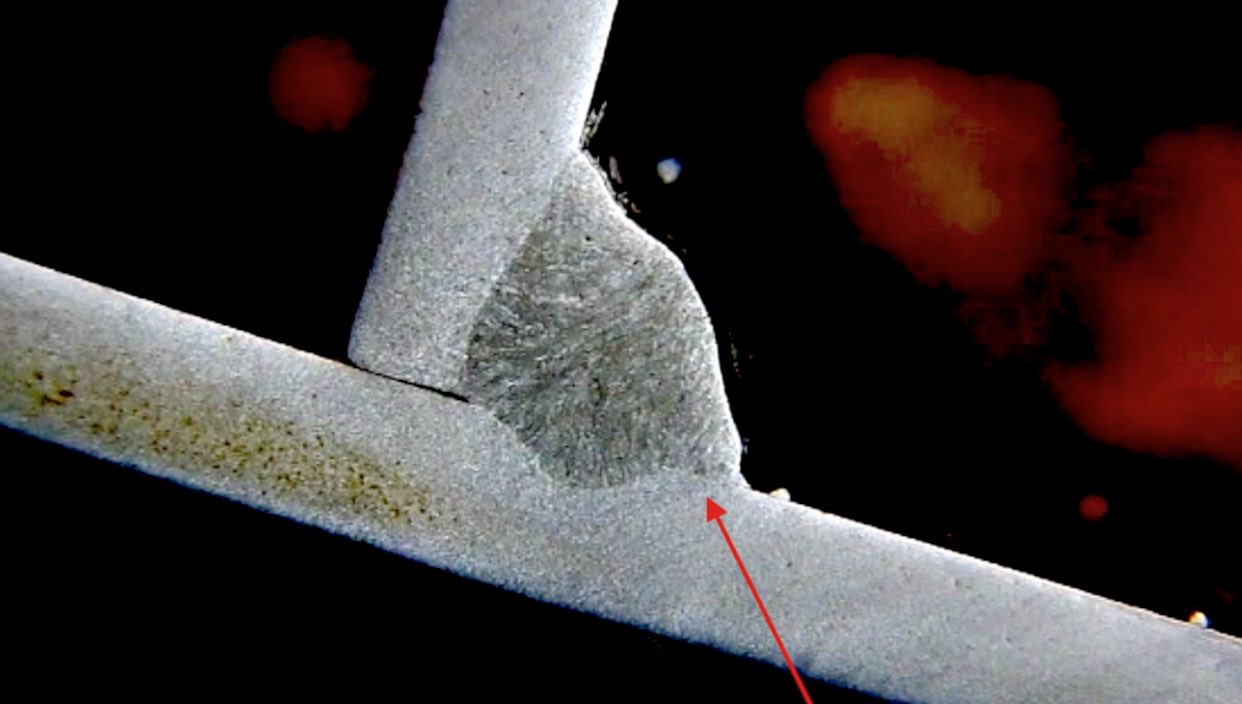

here is the macro test from that weld

Not a huge difference in the arc but notice that there is a straight line near the toe of the weld. I think the mill scale is having an effect on penetration as the wire speed is lowered

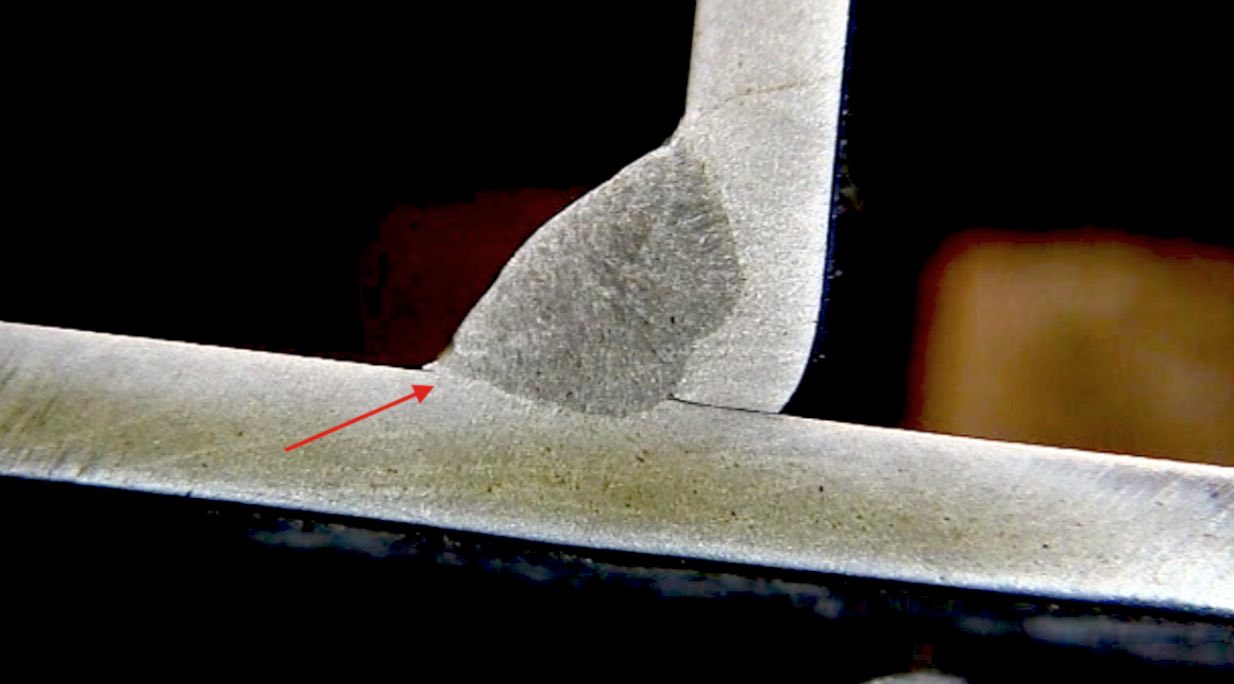

220 inches per minute

lowering the wire speed to 220 definitely produced more spatter and seemed to slow the travel speed a bit.

overall , not a bad result but on the bottom toe, it looked a little cold

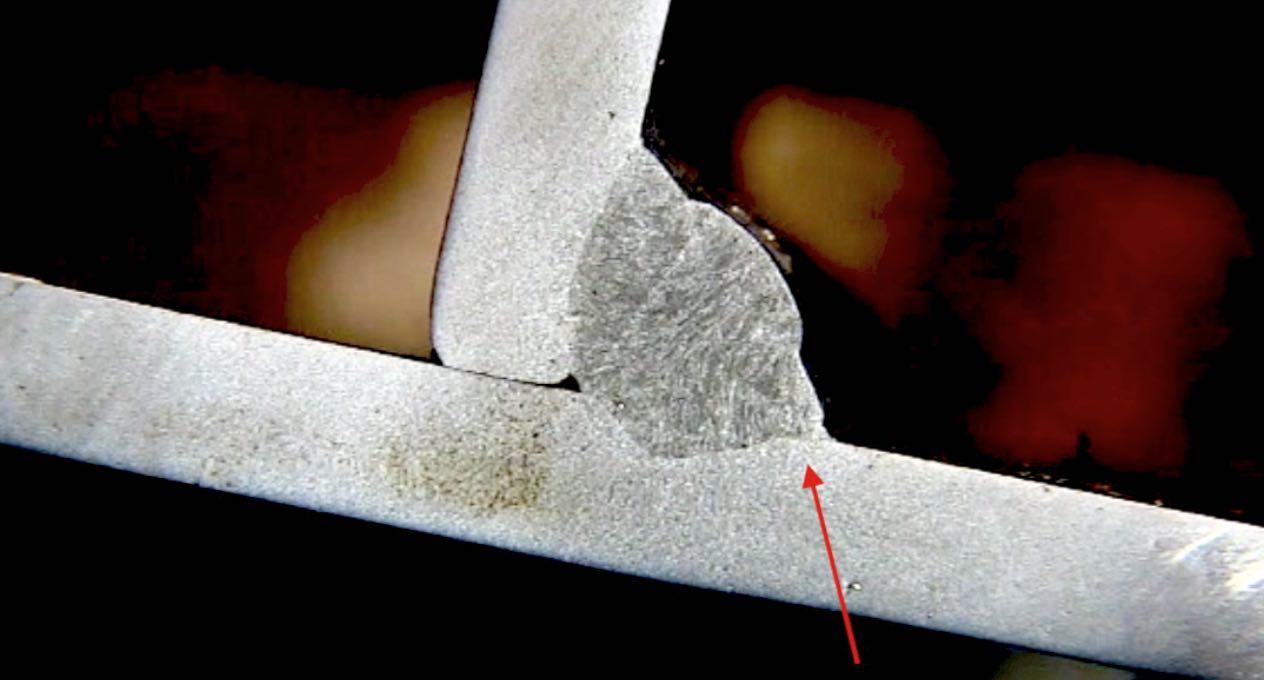

200 ipm

200 inches per minute slowed the travel speed quite a bit.

Since I am not a robot, I think I manually compensated for the lower wire speed by slowing down my travel speed.

Slower travel speed increases heat input and that might explain why at 200ipm, the resulting weld penetration was not that bad.

straight lines are always a red flag. Mill scale is becoming a factor.

170 inches per minute of wire speed

ridiculously low wire speed of 140 ipm

at 140 ipm, the wire was hissing and sputtering and barely welding.

any lower wire feed speed and the wire would melt back to the contact tip.