Mig Welding Downhill

Hidden problems Revealed

Why does mig welding downhill prompt so many arguments?

Can you tell a weld is good just by looking at it?

When it comes to MIG, How clean is clean enough?

This video answers a few of these questions and probably prompts even more questions about mig welding downhill and when uphill is better.

click here to see part 2 of downhill mig

mig welding 1/8" (3.2mm) cold rolled

The first joints I welded in this video were cold rolled finish and roughly 1/8" (3.2mm) thick.

I used the Hobart recommended settings for .024" (.6mm) wire.

One joint test ok, but on a second joint ...using a slightly different gun angle and technique, the results were not that great.

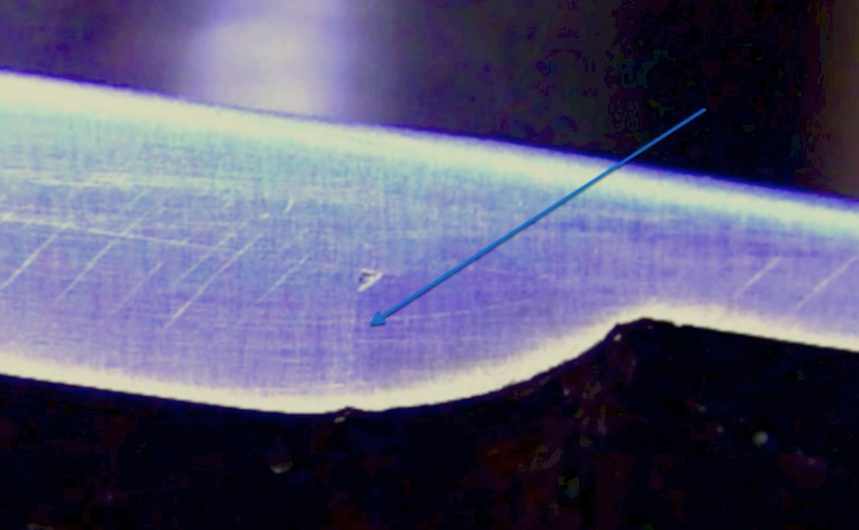

Downhill MIG of 1/4" (6.2mm) hot rolled steel

Just to demonstrate that a visually acceptable weld can be a cold weld with plenty of lack of fusion, I used the same settings as I used for the 11 ga (3.2mm) thick cold rolled steel.

I purposefully hung back in the puddle so that the arc would not reach the root.

Just as suspected, the root of the joint had considerable lack of fusion when I tested the weld by cutting, polishing, and etching.

But cant you just weld hotter and burn thru all that mill scale?

Switching to a heavier machine with .035" (.9mm) wire, I expected better results.

But in fact, the test revealed severe lack of fusion due to the thick mill scale coating.

In fact, the hotter settings yielded a weld worse than the one using small diameter wire and lower amperage.

I suspect cleaning the mill scale would have helped a lot.

But I didn't clean the metal at all because I wanted to show real world conditions welders are up against.

Mig welding Downhill is definitely easier and faster, but...

Not always the best way.

This objective of this video is not to say all downhill mig is bad.

But rather just to show a few things like...

- the need for testing to establish good procedures.

- the need to utilize a welding technique that adequately keeps the arc at the leading edge of the puddle

- the need to remove heavy mill scale prior to welding downhill

- even on 1/8" (3.2mm) cold rolled metal, lack of fusion is possible

My rule of thumb is to weld uphill on 1/4" (6.2mm) and thicker.

I have built lots of metal racks, shelves, and fixtures using hot rolled angle.

Did I clean the hot rolled mill scale from every joint before welding?

Nope.

But I also once welded a manlift work trolley using Mig.

You better believe I ground that clean and welded it hot.

See more videos on MIG