Tig Welding 4140 offset Sockets using hastelloy W tig rod

Furick #8 clear cups now available at weldmonger.com click here to learn more

Whats all this talk about hastelloy W tig rod?

I once had a job welding aircraft engine parts and next door to the weld shop was the main engine shop where they assembled jet engines.

It was very common for a mechanic to walk into the weld shop and ask you to weld a socket to a bar, cut a box end wrench to weld a socket on one end, make an offset in a wrench, or even make some type of specialty wrench.

All these tools involved mixing metals.

4140, chrome vanadium steel, 4130, 17-4 ph, and whatever snap on sockets are made out of.

We welded all of it using hastelloy-W filler rod...

and it always worked.

But Hastelloy W is expensive!

Hastelloy-W as well as most other nickel alloys can cost over 100 dollars per pound. and that is just too much for the average Joe to spend for some versatile rods.

Good news, there are other rods that are almost as good for the type of job I did in this video.

309 stainless is a very affordable rod that can be used effectively for tig welding steels of unknown composition.

312 is very good also.

I just happen to have several pounds of hast W tig rod that I was able to buy for cheap at a scrap yard.

Otherwise, I probably would have selected 309 or 312 tig rod for this little tooling job.

***just remember for critical applications, you need to know the metal type and follow approved welding procedures.

Hastelloy W is a nickel based alloy and is used extensively for repair of jet engine parts.

It is often specified for welding metals that are similar but not quite for example welding 321 stainless to 17-4ph stainless.

all weld metal tensile specimens can go as high as 120ksi.

and that was high enough that when I welded randomly selected scrap pieces to use as a breaker bar on a 1/4" socket welded to 4140 ht steel...the 1/4" drive failed first and that was all the info I needed to know the welds would last just fine in service.

Whats in Hastelloy W?

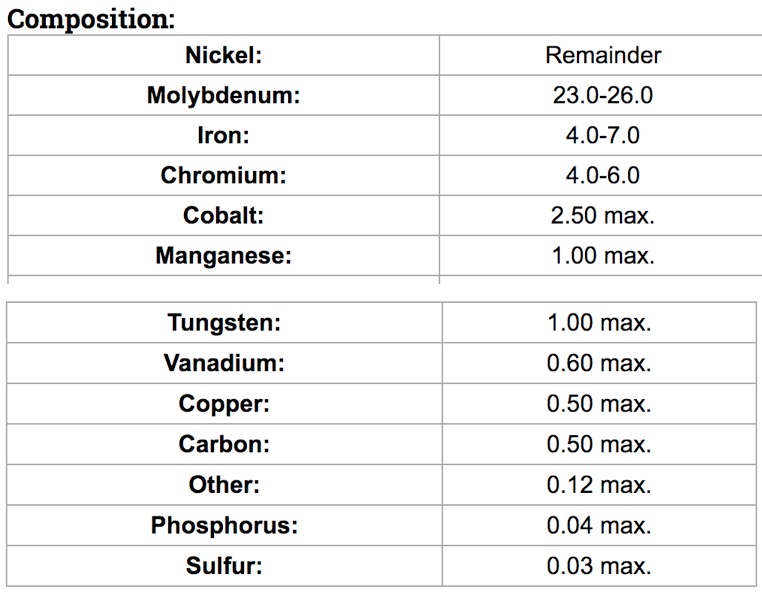

With over 60% nickel, this alloy also contains a 23 -26% molybdenum.