Dual Shield Flux Core Welding Part2

This is part 2 of Dual Shield Flux core welding.

I am using Boehler E71t-1 .045" (1.1mm) wire.

In part one, I experimented using some electrode manipulation to help a vertical weld to flatten out...to help control the puddle.

But I soon learned that using more wire speed was the key to welding uphill.

click here for part 1

visit the weldmonger store to see gloves,tig fingers, gas lens kits, and more...

Andrew Cardin took me to School

Andrew Cardin is a friend of mine and I interviewed him in shortly after he placed 5th in the World Skills welding competition held in Brazil in 2015.

I knew that dual shield flux core welding was part of the pressure vessel project Andrew had to complete for the competitions he was in and ...

From keeping in touch with Andrew, I knew that he had recently taken a dual shield flux core welding test.

So I called Andrew and he took me to school.

Here are 2 tips from Andrew Cardin for dual shield flux core

- First of all, Dual shield flux core wires are all different. Even Different brands that conform to a classification require different settings... and taking time to dial in the best settings takes some work.

- For vertical uphill, less wire

speed does the opposite of what you might think. More wire speed

actually can translate into a flatter uphill bead. ( I increased wire speed from 260ipm to 333ipm with good results)

You might think that increasing wire speed for vertical uphill welds would only make it harder to make a flat face weld.

But actually the opposite is true.

Too little wire speed makes for less arc force and also a puddle that is too fluid.

Increasing the wire speed from 260 to 333ipm made a distinct difference on a vertical uphill fillet weld.

Why is that?

From the look of the arc, increasing wire speed to 333 from 260ipm changed the arc quite a bit.

The tip of the wire looked like a sharp pencil...Instead of soft droplets of molten metal melting into the puddle there were small droplets of metal transferred into the puddle with force...and that arc force caused the puddle to fan out instead of piling up.

Same thing is true when overhead welding with stick or mig.

Your first guess might lead you to turn down the amperage or wire speed for fear of the welding falling out due to gravity.

But the opposite is true.

Settings that work for flat and horizontal also work for overhead.

you need some arc force to help the weld bead to fan out.

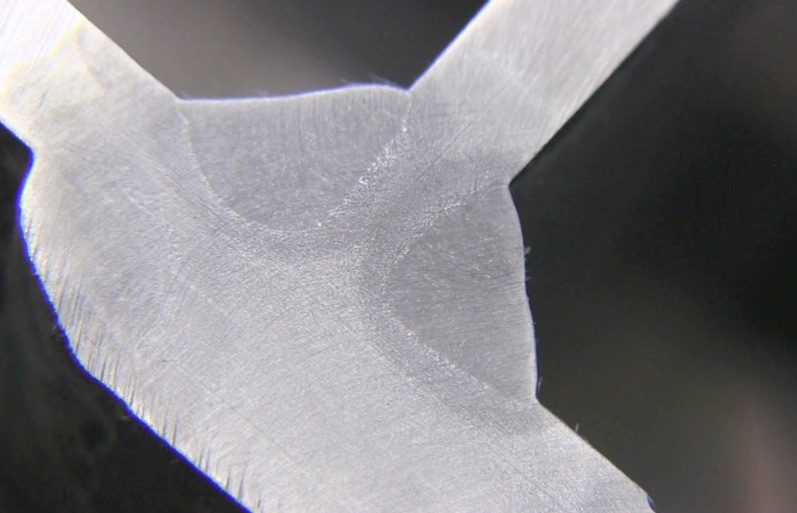

The etch test revealed exactly what the arc seemed to convey.

A nice weld nugget profile...nice penetration while maintaining a flat weld face.

Related pages:

Self Shielded Flux Core welding part 1