TIG Welding Aluminum D17.1 Certification Test

see more tig welding aluminum videos or go to the main TIG welding page

...Introducing the New WeldMonger Challenger TIG kit that includes the most frequently used Cups.

There are 7 main metal groups listed in D17.1 and a few sub groups but aluminum alloys is group 4 and aluminum is one of those metals used a lot in aerospace welding.

A 2f tee joint is a simple joint but the AWS D17.1 acceptance criteria for .063" and thinner is strict...so it has one of the highest failure rates of any test used for aerospace welding certification.

The standard for aerospace welding certification used to be mil std 1595a.

Mil Std 1595a allowed a certain amount of lack of fusion in tee joints .063" and thinner. The limit was .3 of the actual throat size of the fillet weld on a tee joint weld.

Around 2001 AWD D17.1 was approved and published and was written to replace mil std 1595a as well as mil std 2219. ( both had been converted to ams documents as many mil standards were converted during that era)

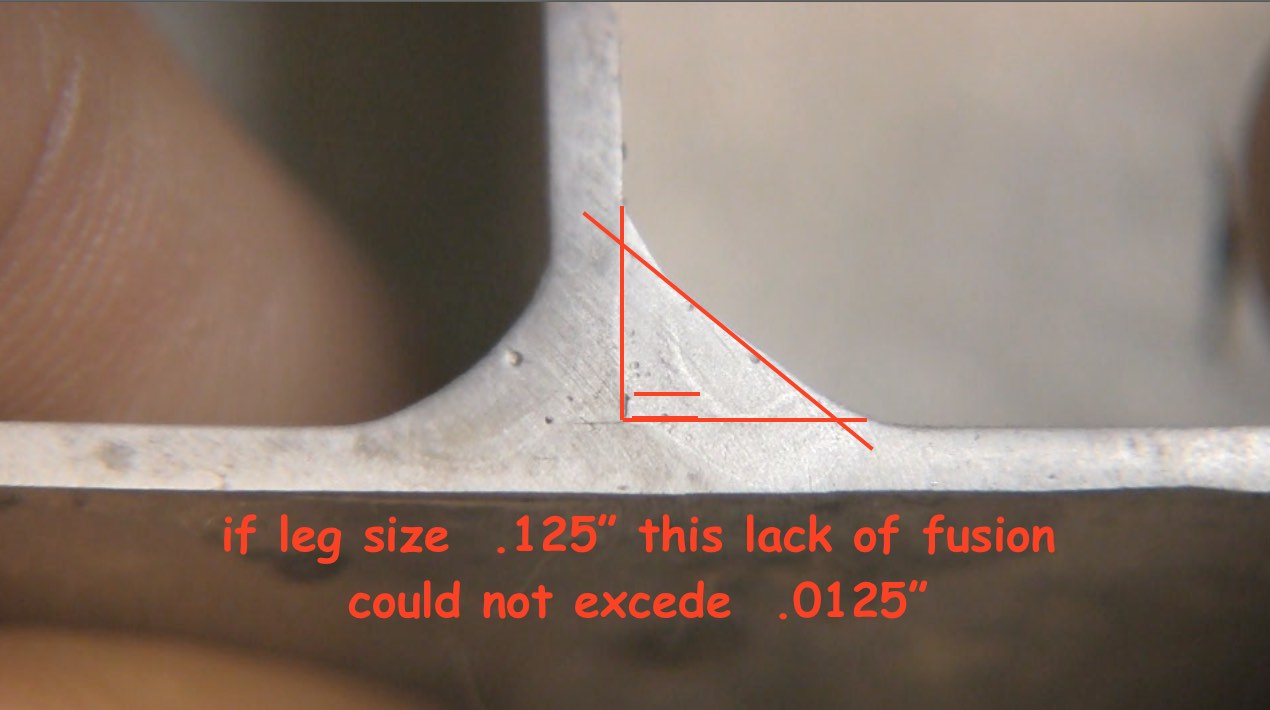

During the process of many tedious committee meetings,( I attended several of these myself) the lack of fusion limit for fillet weld tee joints went from .3 of actual throat...to .1 of leg size by a fluke.

Yes a fluke. and once if was proposed, it was approved and published.

right or wrong, it is a requirement now.

So that is why I recommend a larger than necessary weld size on the aluminum tee joint fillet weld test...because if you lay down the minimum leg size, and have the tiniest bit of lack of fusion, you will almost certainly fail the test.

Whereas if you lay down a fillet weld that is a bit larger than the minimum fillet weld required by AWS D17.1, a small amount of lack of fusion has a chance of passing the acceptance criteria.

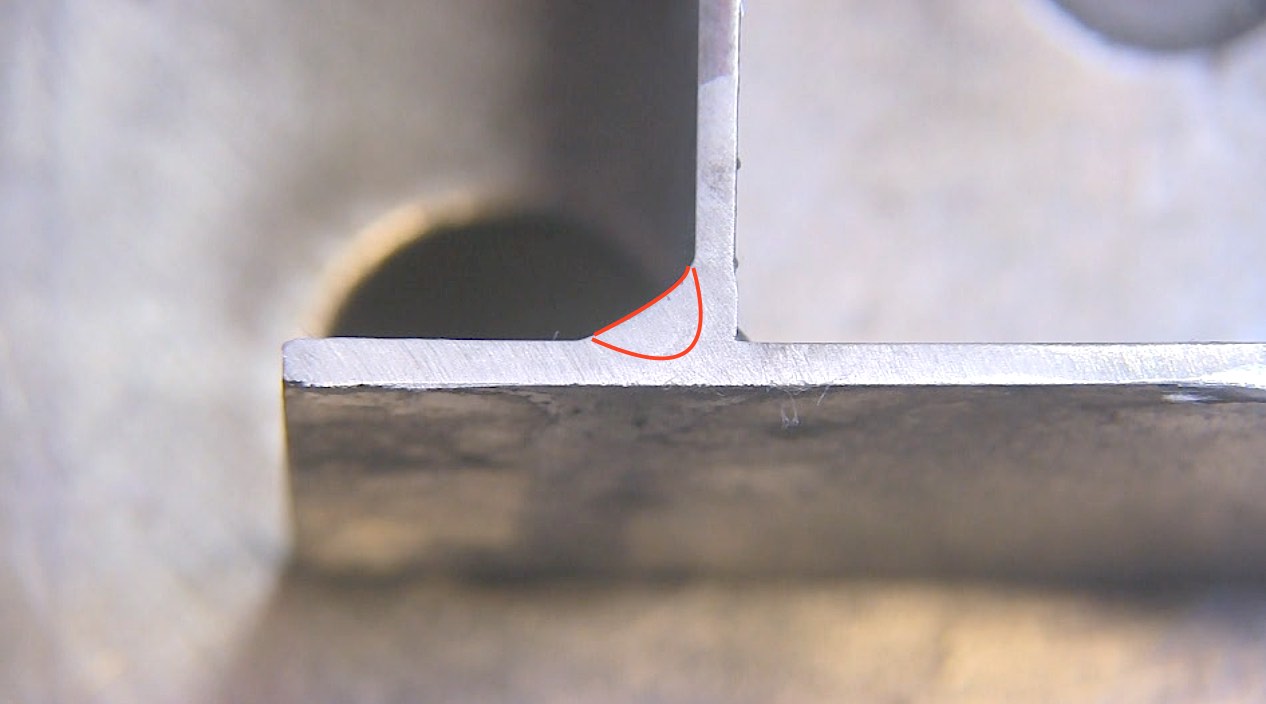

Suck Back aka Melt Back in Tig Welding Aluminum Tee joints

What is Suck Back? what is Melt Back?

They are the same thing.

When you are tig welding aluminum, specifically a thin tee joint fillet weld-.063" and thinner, you walk a fine line between achieving fusion all the way into the root of the joint...and melt back or suck back which happens when you melt all the way thru.

Melt thru is slighty different than melt back. Melt thru is when you penetrate all the way thru the back side.

It is usually permissible to have some melt thru on aluminum tee joints .063" and thinner but its not desirable.

Melting thru is not automatically a defect..in fact there are limits for how much you can melt thru on a tee joint and as long as you protrude with reinforcement, the joint can still be ok.

But melt back or suck back is when the back side is below flush.

When the effect of melt back or suck back is that the overall cross sectional thickness is reduced below the thickness of the base metal, that is considered a failure.

So in order to increase your chances of passing the D17.1 aluminum tee joint certification test, I recommend going for a larger than minimum leg size and I also recommend using a forward a back technique that minimizes lack of fusion and also minimizes melt back/suck back.