AC Waveforms and Advanced AC Tig

Some newer inverter tig welders have a setting called "AC Waveforms".

Typically, those are advanced square wave, soft square wave, sine wave, and triangle wave.

All these AC Waveforms have different characteristics and provide different bead profiles and penetration.

Nothing is carved in stone as to which waveform is best for what application. Its up to the weldor to use the best waveform for each application.

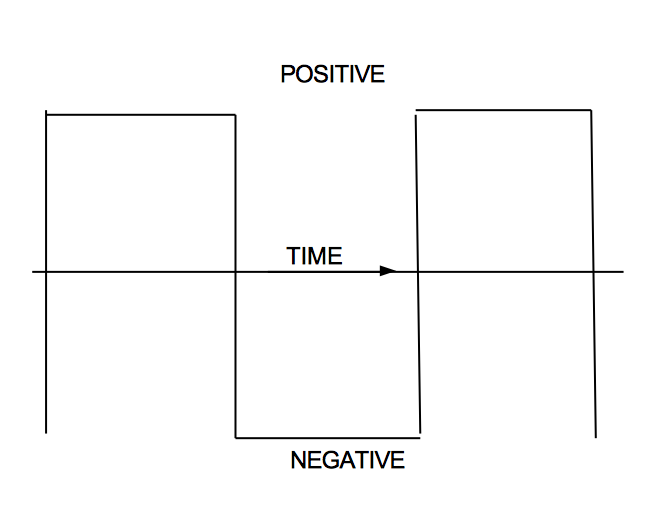

Advanced Square Wave

I usually use advanced square wave for everything. It seems to me that I can get more heat input out of advanced square wave form.

I am often welding with 200 amp inverters machines and sometimes I am full pedal. Advanced square wave seems to provide the most heat input.

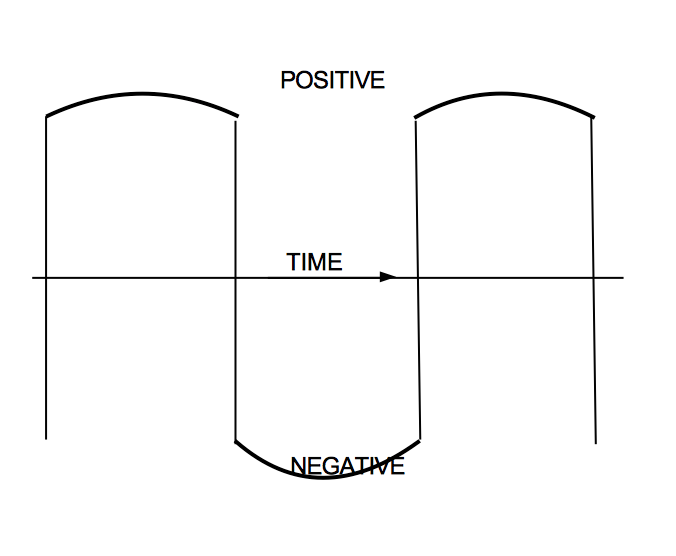

soft square wave

This AC Waveform is the default setting on some tig inverters.

It is said to have a bit smoother arc than advanced and is even described as more "buttery" by some welders.

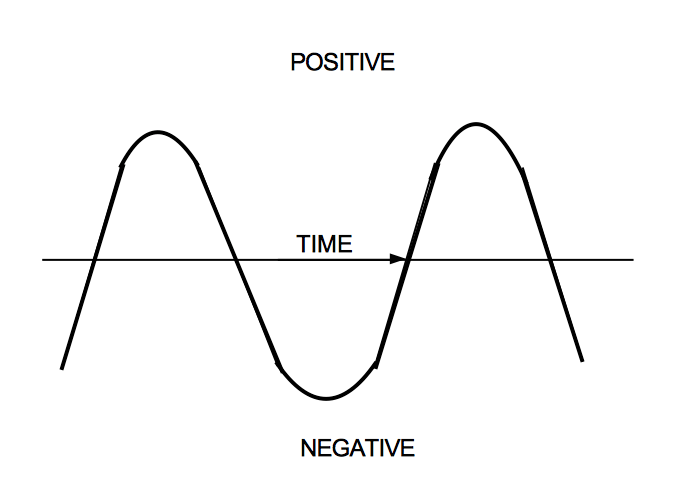

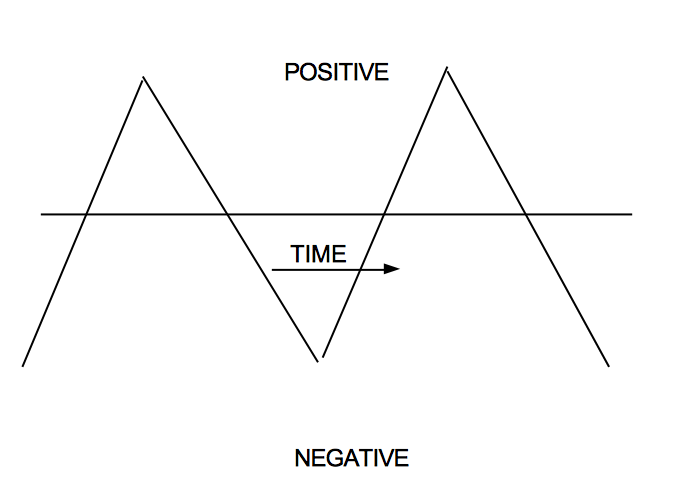

AC Waveform - Sine Wave

The Sine Wave AC Waveform is like older transformer type machines.

I think companies added the sine wave form to mimick the old machines for older welders who prefer older machines.

Nothing wrong with sine wave at all.

triangle wave

see what miller electric has to say about ac wave forms

Triangle waveform is said to work well on thin sheet metal.

but it is also said that it puddles the metal quicker than other waveforms.

Not sure which is true but I have used it on thin aluminum with good results.

here is a link to an aluminum pie cut project where triangle wave form was used.

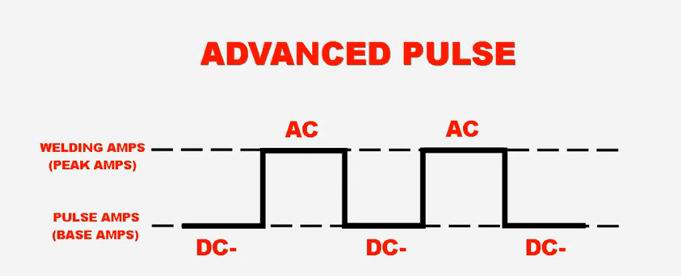

What is Advanced AC Pulse and how does it compare to AC Waveforms

Advanced AC Pulse alternates between DCEN and AC and it provides deeper penetration than all the other AC waveforms.

I set the pulses per second to 2pps , the pulse time to 50%, and the background current to 100% because the background current is the DCEN pulse and I wanted maximum heat input and penetration.

When I cut, polished, and etched to compare the AC waveforms I didnt see much difference at 175 amps.

But using the same 175 amps and advanced pulse, penetration was much deeper.

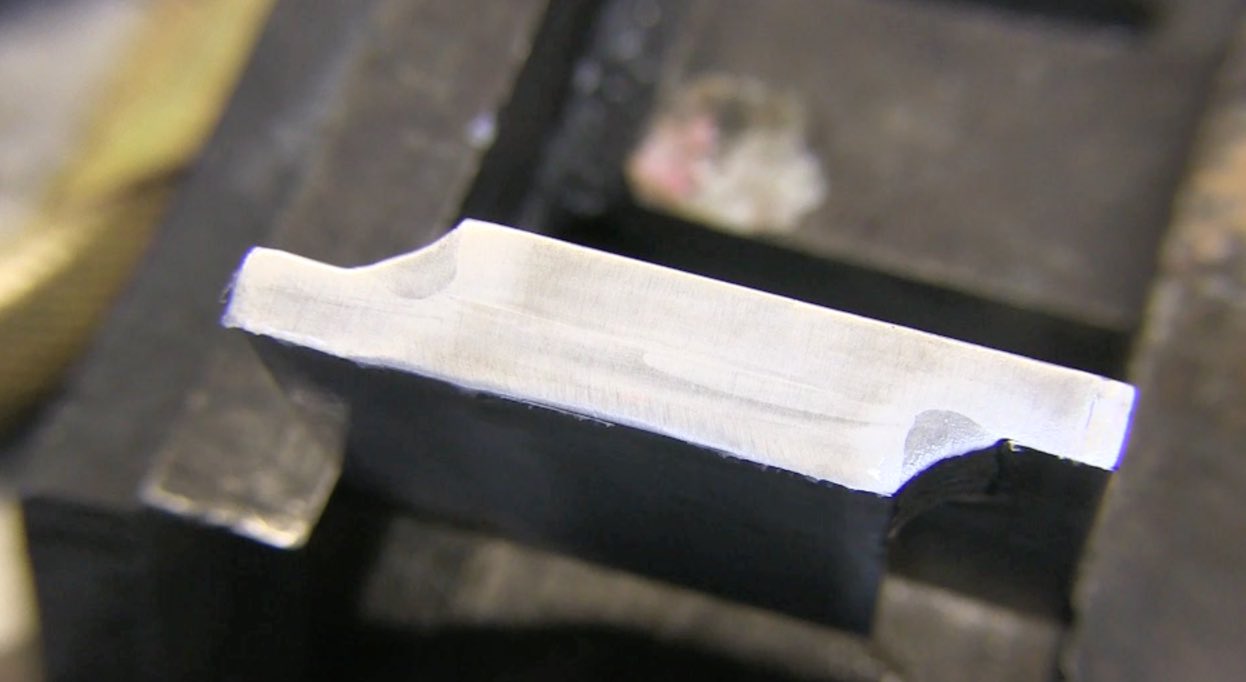

Lap joint on 1/4" (6.2mm) 6061 aluminum using advanced AC pulse

I increased amps to 200 for the lap joint used 3/32" (2.4) 2% lanthanated electrode and 1/8" (3.2mm) 4943 filler metal.

Using 2 pps, I dipped filler rod every other pulse.

A quick cut and etch revealed good penetration into the root.