7010 Overhead Branch practice

see more overhead welding videos

In this video you will see Andrew Cardin weld a 7010 overhead branch practice plate.

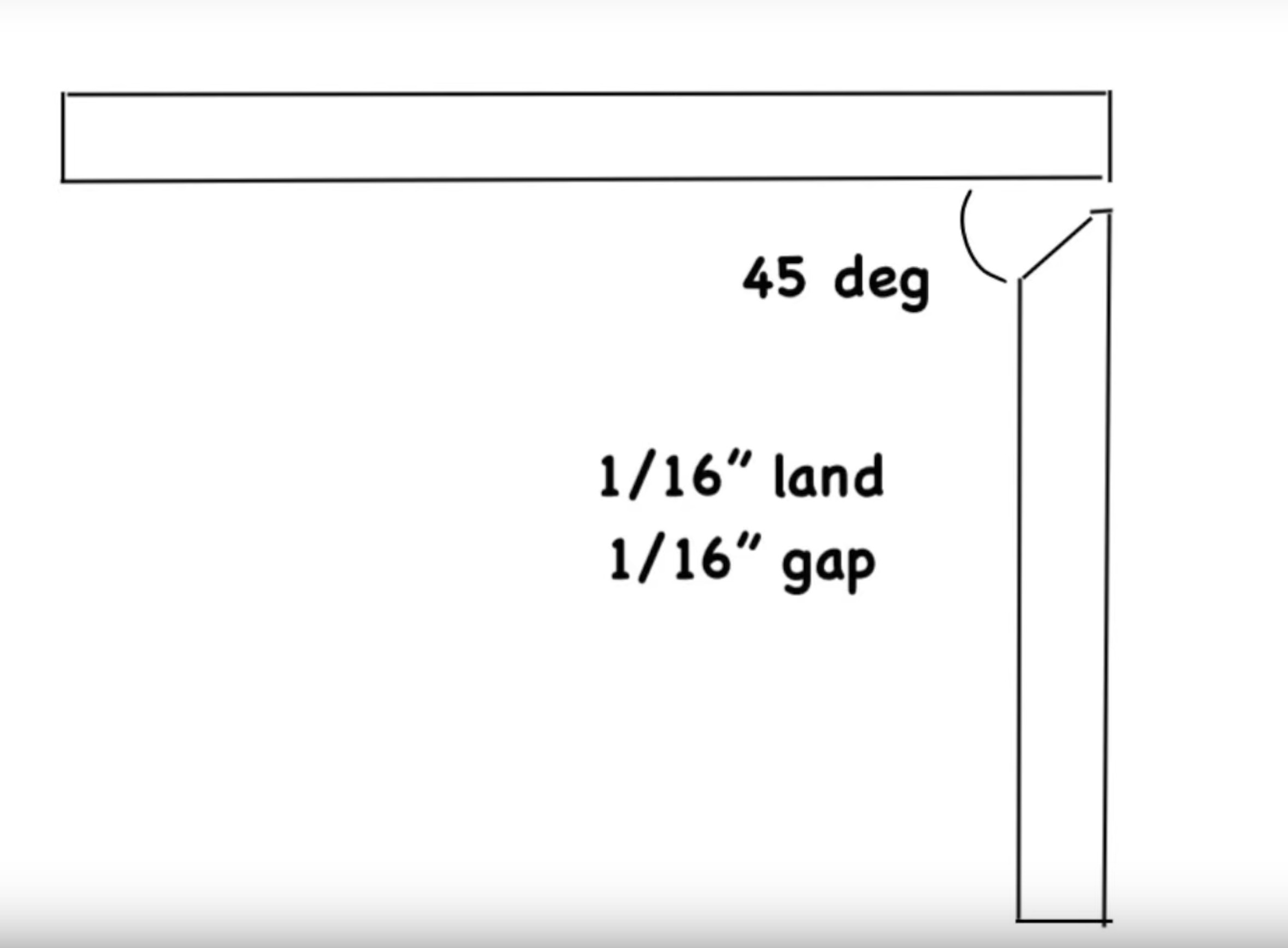

The joint configuration is as follows:

3/8' A36 plate (from Trieng.com)

one piece beveled to 45 degrees and one piece with no bevel.

7010 Overhead 5/32" root and hot

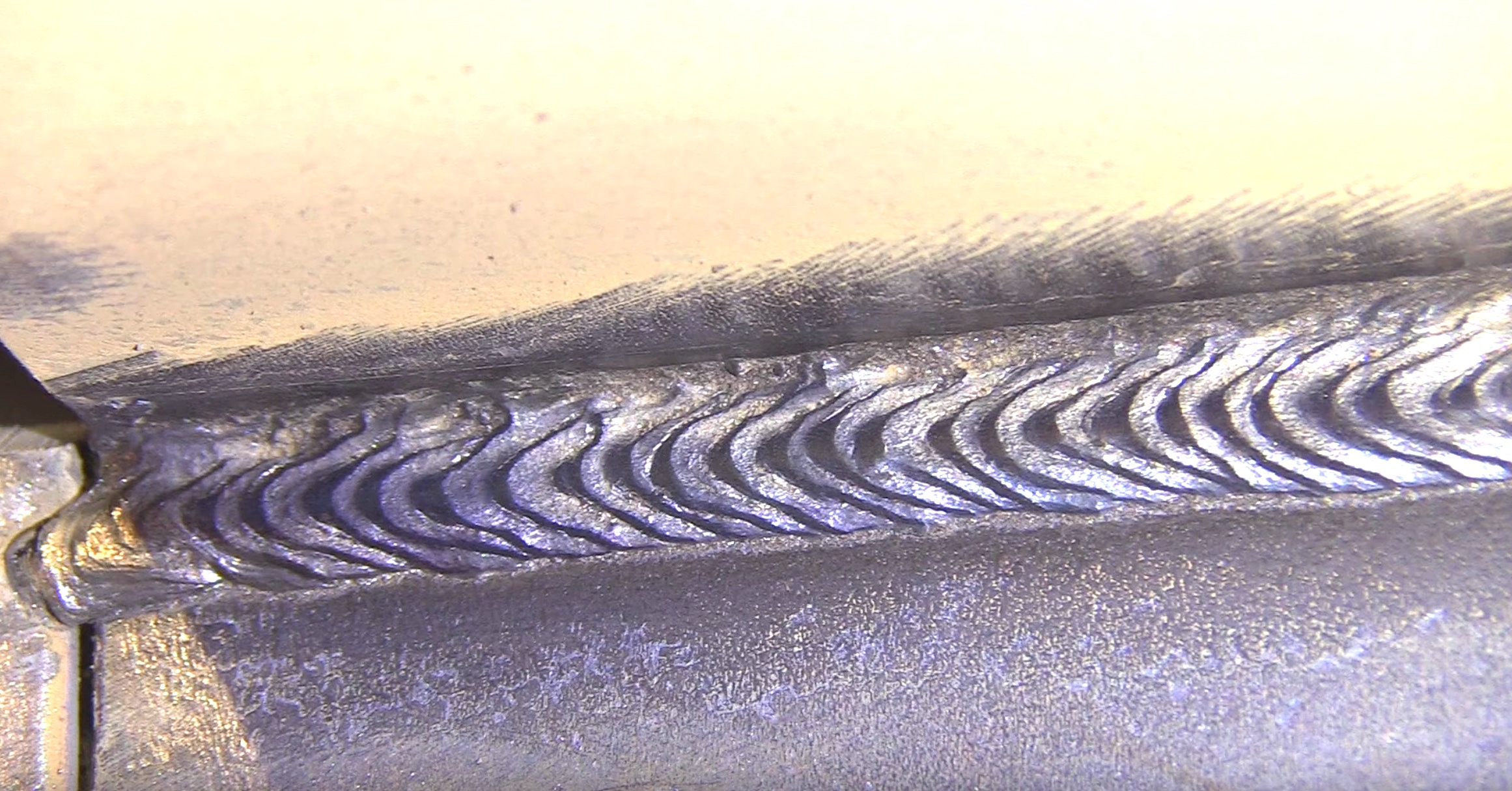

Andrew welded the overhead 7010 root pass using 5/32" electrodes at around 135 amps using an Esab Rebel 285.

After the root pass, Andrew increased amps to 145 amps still using the 5/32" electrode.

7010 fill and cap

For the rest of the joint he changed up to 3/16" 7010 electrodes and around 155 amps.

When on the job welding gas piping, Andrew is usuall using a Lincoln Vantage engine drive welder or other engine drive but since we were at JD's shop, we used the Esab Rebel and it actually has a pretty darn good 6010/7010 arc.

Not all machines burn a cellulose 6010/7010 electrode well so its worth noting that Esab did their homework in making a machine that not only will burn a 6010, but does so with an arc that works well for open roots.

Watching this 7010 overhead root go in was pretty impressive.

Of course Andrews eyes and hands are the biggest factor.

CLAMS

At the risk of sounding like a broken record...

The Acronym CLAMS is a great checklist for anyone learning to stick weld and I find it especially helpful in teaching to help me cover all the bases.

CURRENT

The word Current can be used to remind you of not only amperage, but voltage and polarity. 7010 and 6010 electrodes can be used on both dcep and dcen polarity. For this video, we followed the procedure that Andrews company most often uses and polarity was set to dcep.

Voltage is controlled by arc length and the power source and definitely has an affect on how a 6010 or 7010 burns.

LENGTH OF ARC

Controls voltage, and is a variable that can be manipulated to make the root pass go in better. On certain power sources, there is a feature called "arc control" or "dig" that also affects the arc by sensing voltage changes due to arc length.

ANGLE OF ELECTRODE

Angle of travel and electrode makes a difference also but fortunately, electrode angle can be very forgiving. I say its fortunate because sometimes there are things in the way that preven an optimal electrode angle

MANIPULATION OF PUDDLE

with fast freeze cellulose electrodes like 6010 and 7010, manipulation of the electrode allows the molten puddle to freeze and that is what makes this type of elecrode so useful for open roots.

SPEED OF TRAVEL

travel speed is another important thing to consider. Travel speed varies a lot depending on whether a root pass is being welded , or the last bead on a cover pass.