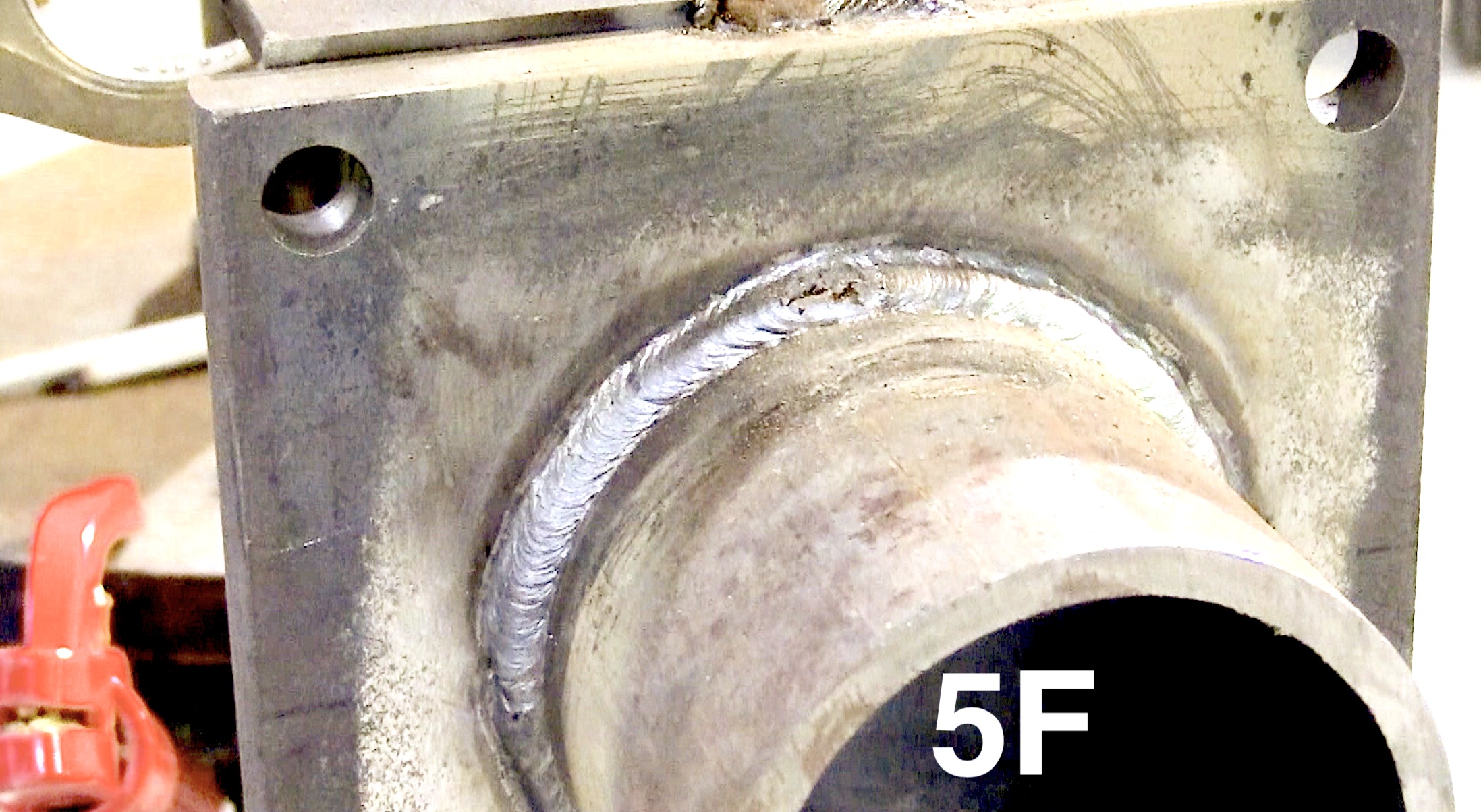

5F Welding Position with 7018 5/32"

This is a 5F welding video using 7018 5/32" low hydrogen electrodes .

A 5F weld joint is a tube welded to a plate where the axis of the tube is horizontal and the plate is vertical.

A 5F weld joint is a bit more challenging than a 2F.

...and the thing that makes it difficult is mainly body positioning.

maintaining a tight arc along with a favorable rod angle while constantly repositioning your body can be a challenge.

I would prefer to weld this joint with a 1/8" 7018 but there are some procedures that demand using a 5/32" 7018 so that is why we are using 5/32".

when the procedure specifies 5/32", that is what you use.

5/32" 7018 is a bit more difficult for 5f welding position like this but only slightly more difficult.

And one thing is for sure....If you can do this 5f joint with a 5/32" rod, you can certainly do it with a 1/8".

Amperage was set to 145 which is on the lower end of the amperage range for 5/32" 7018. ( amperage range for 5/32" 7018 is around 130-210).

With newer inverter welders like the 210mp used in this video, there is usually a setting called "arc control" or "Dig".

Because a fairly low amperage of 145 was used, it helps to set the Dig setting high to prevent sticking the electrode.

see a video of this same tube to plate weld in 4F overhead position

Low hydrogen Electrodes 5f welding

When to use a low hydrogen electrode...

- when a procedure specifies a low hydrogen electrode

- high strength steels

- thick steel

low hydrogen electrodes like 7018 are specified in qualified weld procedures to prevent hydrogen induced cracking.

Hydrogen atoms have the ability to enter the molten puddle and then also to diffuse into the base metal in the heat affected zone (HAZ).

When hydrogen diffuses into the HAZ, it causes stress and cracking.

7018 and other low hydrogen electrodes are specified to prevent hydrogen induced cracking but they most be maintained in a rod oven at a specified temperature in order to remain low hydrogen.

7018 can be used fresh out of their sealed containers but can only be left out in the atmosphere for a few hours before they must be baked in a rod oven. And there are even stipulations for how many times they can be reheated.

Otherwise, they are no longer low hydrogen electrodes.

Hydrogen is especially problematic with high strength steels.

In fact, there are documented failures of high strength steel lowboy trailers where 6010 electrodes were used for a repair instead of low hydrogen electrodes.